Graphite lubricant offers superior adhesion and long-lasting lubrication compared to graphite powder, making it ideal for applications requiring reduced friction and wear. While graphite powder is effective for dry lubrication and prevents metal-on-metal contact, it can be messy and less durable in high-stress environments. Choosing between graphite lubricant and powder depends on the specific needs of the project, such as exposure to moisture and the desired ease of application.

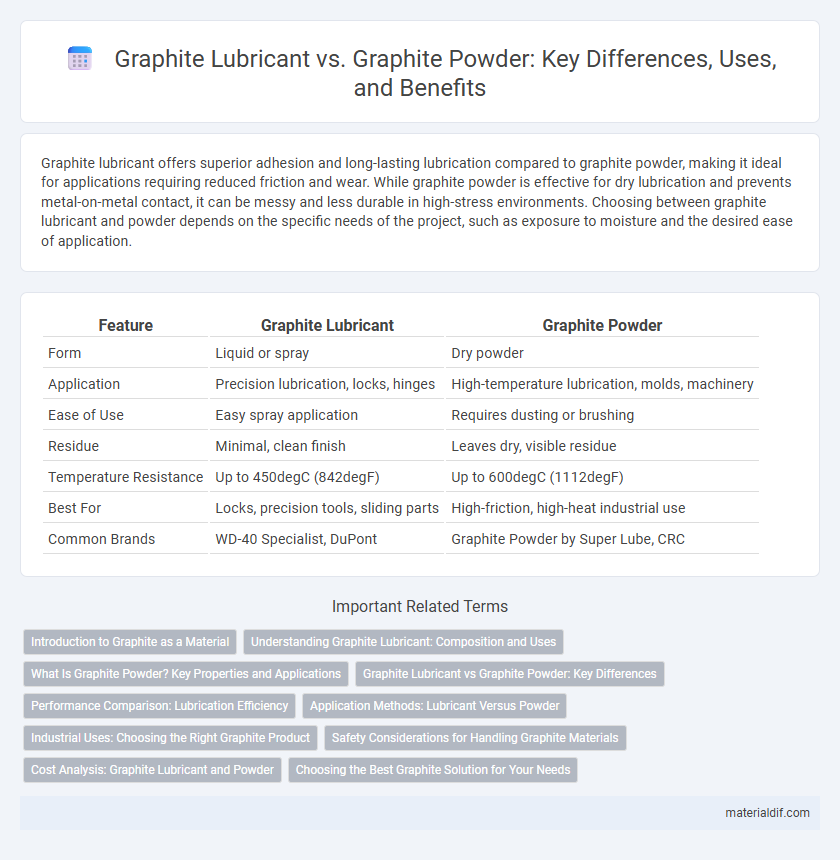

Table of Comparison

| Feature | Graphite Lubricant | Graphite Powder |

|---|---|---|

| Form | Liquid or spray | Dry powder |

| Application | Precision lubrication, locks, hinges | High-temperature lubrication, molds, machinery |

| Ease of Use | Easy spray application | Requires dusting or brushing |

| Residue | Minimal, clean finish | Leaves dry, visible residue |

| Temperature Resistance | Up to 450degC (842degF) | Up to 600degC (1112degF) |

| Best For | Locks, precision tools, sliding parts | High-friction, high-heat industrial use |

| Common Brands | WD-40 Specialist, DuPont | Graphite Powder by Super Lube, CRC |

Introduction to Graphite as a Material

Graphite, a naturally occurring form of carbon, exhibits a layered structure that provides excellent lubricating properties due to its low friction and high thermal stability. Graphite lubricant contains finely dispersed particles suspended in a carrier fluid, ideal for applications requiring smooth motion and reduced wear on moving parts. In contrast, graphite powder is a dry, granular material favored for penetration into tight spaces and high-temperature environments where liquid lubricants might evaporate or degrade.

Understanding Graphite Lubricant: Composition and Uses

Graphite lubricant typically consists of finely powdered graphite suspended in a liquid carrier such as oil, water, or solvent, enabling easy application and enhanced adhesion to surfaces for effective lubrication. Its composition allows it to form a thin, durable film that reduces friction and wear in mechanical parts, bearings, locks, and electrical contacts. Common uses include automotive maintenance, industrial machinery, and precision instruments where clean, dry lubrication and corrosion resistance are essential.

What Is Graphite Powder? Key Properties and Applications

Graphite powder is a fine, dry form of graphite known for its excellent lubricating properties, high thermal conductivity, and resistance to chemical corrosion. Key applications include use as a dry lubricant in locks, bearings, and molds, as well as in batteries, brake linings, and lubricants for environments where wet lubricants are unsuitable. Its unique ability to reduce friction without the mess of oil-based lubricants makes it essential in industrial and mechanical settings requiring contamination-free lubrication.

Graphite Lubricant vs Graphite Powder: Key Differences

Graphite lubricant contains a liquid carrier that enhances application ease and provides long-lasting lubrication, while graphite powder is a dry substance ideal for high-temperature environments and dust-sensitive applications. Graphite lubricant reduces friction more effectively on moving parts due to its adhesive properties, whereas graphite powder excels as a dry film lubricant for mechanisms exposed to contaminants. The choice between graphite lubricant and graphite powder depends on specific operational conditions such as temperature, exposure to dust, and the need for wet or dry lubrication.

Performance Comparison: Lubrication Efficiency

Graphite lubricant outperforms graphite powder in lubrication efficiency by providing a consistent, uniform coating that reduces friction more effectively under varying loads and temperatures. The lubricant formulation enhances graphite's inherent layered structure, allowing better film formation and longer-lasting protection against wear and corrosion. In contrast, graphite powder often suffers from inconsistent application and susceptibility to displacement, leading to less reliable and shorter-term lubrication performance.

Application Methods: Lubricant Versus Powder

Graphite lubricant is applied as a liquid or spray, allowing it to penetrate tight spaces and provide long-lasting lubrication on mechanical parts, hinges, and locks. Graphite powder, in contrast, is typically dusted or sprinkled, making it suitable for dry environments where a clean, residue-free lubrication is required, such as in firearms or precision instruments. Choosing between graphite lubricant and powder depends on the specific application method and the desired level of moisture and residue control.

Industrial Uses: Choosing the Right Graphite Product

Graphite lubricant offers superior adhesion and long-lasting lubrication ideal for heavy machinery and high-friction environments in industrial settings. Graphite powder provides excellent dry lubrication and conductivity, making it suitable for applications requiring precision and minimal residue such as in electrical contacts and locks. Selecting the right graphite product depends on the specific industrial application's need for durability, lubrication type, and contamination sensitivity.

Safety Considerations for Handling Graphite Materials

Graphite lubricant offers enhanced safety in handling due to its reduced dust generation compared to graphite powder, minimizing respiratory hazards and inhalation risks. Graphite powder presents increased airborne particle potential, necessitating strict use of personal protective equipment (PPE) such as masks and gloves to prevent skin irritation and respiratory issues. Proper ventilation and dust control measures are essential when working with graphite powder to maintain a safe environment and reduce exposure to fine particles.

Cost Analysis: Graphite Lubricant and Powder

Graphite lubricant generally incurs higher upfront costs due to its formulation with additives and carriers, whereas graphite powder is more cost-effective as a raw, purified material. The longevity and reduced maintenance requirements of graphite lubricant can offset the initial expense, making it economically viable in high-friction or load-bearing applications. In contrast, graphite powder suits budget-sensitive projects requiring basic lubrication without complex application needs.

Choosing the Best Graphite Solution for Your Needs

Graphite lubricant offers superior wear reduction and corrosion protection ideal for mechanical parts requiring smooth motion, while graphite powder excels in dry lubrication applications where residues must be minimal. Selecting the best graphite solution depends on factors such as operating temperature, environmental conditions, and the specific machinery involved. For high-load or high-speed environments, graphite lubricant ensures durable performance, whereas graphite powder suits lightweight applications and electrical conductivity needs.

Graphite Lubricant vs Graphite Powder Infographic

materialdif.com

materialdif.com