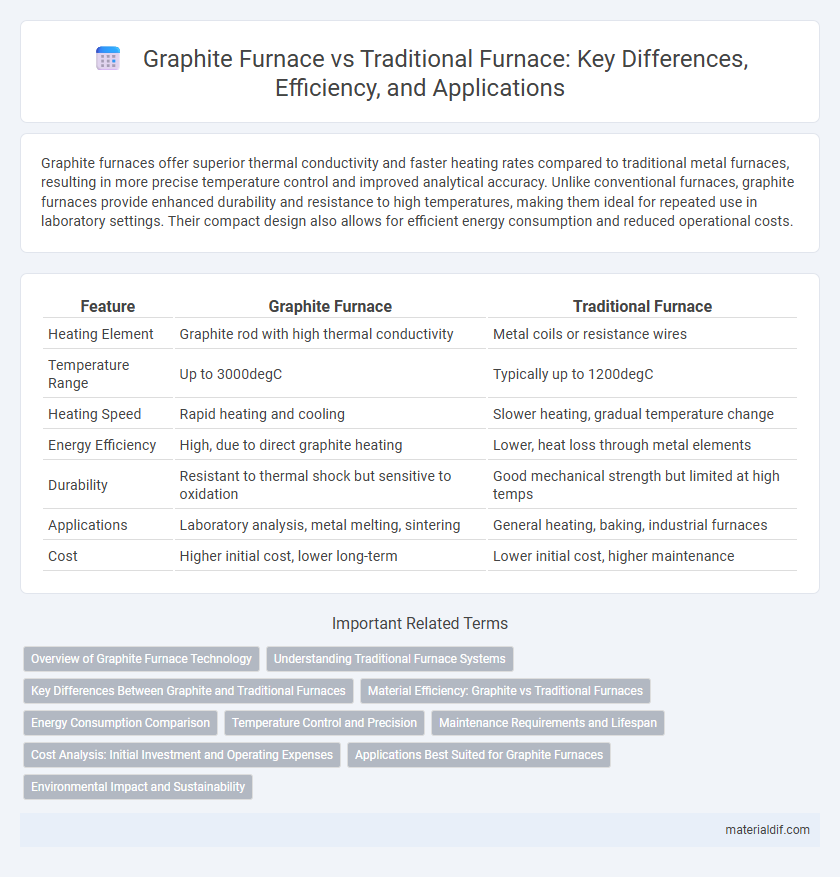

Graphite furnaces offer superior thermal conductivity and faster heating rates compared to traditional metal furnaces, resulting in more precise temperature control and improved analytical accuracy. Unlike conventional furnaces, graphite furnaces provide enhanced durability and resistance to high temperatures, making them ideal for repeated use in laboratory settings. Their compact design also allows for efficient energy consumption and reduced operational costs.

Table of Comparison

| Feature | Graphite Furnace | Traditional Furnace |

|---|---|---|

| Heating Element | Graphite rod with high thermal conductivity | Metal coils or resistance wires |

| Temperature Range | Up to 3000degC | Typically up to 1200degC |

| Heating Speed | Rapid heating and cooling | Slower heating, gradual temperature change |

| Energy Efficiency | High, due to direct graphite heating | Lower, heat loss through metal elements |

| Durability | Resistant to thermal shock but sensitive to oxidation | Good mechanical strength but limited at high temps |

| Applications | Laboratory analysis, metal melting, sintering | General heating, baking, industrial furnaces |

| Cost | Higher initial cost, lower long-term | Lower initial cost, higher maintenance |

Overview of Graphite Furnace Technology

Graphite furnace technology employs a small graphite tube as a high-temperature heating element, enabling highly sensitive atomic absorption spectrometry for trace metals detection. Unlike traditional furnaces that rely on larger, less uniform heating sources, graphite furnaces offer rapid temperature ramping, precise control, and minimal sample volume requirements. This technology enhances analytical accuracy and efficiency in applications such as environmental testing, clinical analysis, and materials science.

Understanding Traditional Furnace Systems

Traditional furnace systems rely on resistance heating elements to raise temperatures gradually, which can result in longer warm-up times and less precise temperature control compared to graphite furnaces. These systems typically use ceramic or metal elements that heat the sample indirectly, often causing uneven temperature distribution and limited maximum temperatures. Understanding these limitations highlights why graphite furnaces offer improved efficiency and accuracy in analytical applications.

Key Differences Between Graphite and Traditional Furnaces

Graphite furnaces offer superior thermal conductivity and rapid heating capabilities compared to traditional furnaces, enabling more precise temperature control and energy efficiency. Unlike conventional furnaces that rely on metal or ceramic heating elements, graphite furnaces use graphite electrodes which withstand higher temperatures and reduce contamination risks during processing. These advantages make graphite furnaces ideal for applications requiring fast heating cycles and high-purity environments, such as advanced semiconductor manufacturing and material testing.

Material Efficiency: Graphite vs Traditional Furnaces

Graphite furnaces exhibit superior material efficiency compared to traditional furnaces due to their enhanced thermal conductivity and rapid heating capabilities, which reduce energy consumption and minimize material waste. The high thermal stability and uniform temperature distribution in graphite furnaces enable precise control over processing conditions, leading to less degradation of raw materials. Traditional furnaces often suffer from slower heating rates and uneven temperature profiles, resulting in higher material loss and lower overall efficiency.

Energy Consumption Comparison

Graphite furnaces consume significantly less energy compared to traditional furnaces due to their efficient heat transfer properties and rapid temperature ramp-up times. The high thermal conductivity of graphite reduces energy loss, allowing precise control over the heating process with minimal power input. This energy efficiency translates to lower operational costs and a reduced environmental footprint in industrial applications.

Temperature Control and Precision

Graphite furnaces offer superior temperature control and precision compared to traditional furnaces, utilizing rapid electrical resistance heating that enables precise temperature ramping and uniform heat distribution. This advanced control minimizes thermal gradients and enhances analytical accuracy, especially in applications like atomic absorption spectroscopy. Traditional furnaces, relying on less responsive heating methods, often exhibit slower temperature changes and less uniform heat, limiting their precision in temperature-sensitive processes.

Maintenance Requirements and Lifespan

Graphite furnaces require less frequent maintenance due to their high thermal conductivity and resistance to thermal shock, which minimizes wear and extends component life. Traditional furnaces often experience faster degradation of heating elements and insulation, necessitating more regular repairs and inspections. The lifespan of graphite furnaces typically surpasses traditional models, with graphite elements lasting significantly longer under consistent operational conditions.

Cost Analysis: Initial Investment and Operating Expenses

Graphite furnaces typically require a higher initial investment compared to traditional furnaces due to advanced technology and material costs. Operating expenses for graphite furnaces are generally lower, benefiting from improved energy efficiency and reduced maintenance requirements. Over the long term, the total cost of ownership often favors graphite furnaces because of savings in energy consumption and extended service life.

Applications Best Suited for Graphite Furnaces

Graphite furnaces excel in atomic absorption spectroscopy for trace element analysis due to their high sensitivity and low detection limits, making them ideal for biological, environmental, and geological sample testing. Unlike traditional flame furnaces, graphite furnaces allow precise temperature control and require smaller sample volumes, enhancing accuracy in detecting metals such as lead, cadmium, and arsenic. Their application is particularly suited for scenarios demanding high precision in metal quantification where sample availability is limited or analyte concentrations are extremely low.

Environmental Impact and Sustainability

Graphite furnaces significantly reduce energy consumption compared to traditional furnaces, lowering greenhouse gas emissions and carbon footprint in metal processing industries. The precise temperature control of graphite furnaces enhances product quality and reduces waste generation, contributing to sustainable manufacturing practices. Their longer lifespan and recyclability of graphite components further support environmental sustainability by minimizing resource depletion.

Graphite Furnace vs Traditional Furnace Infographic

materialdif.com

materialdif.com