EVA foam offers superior cushioning and flexibility compared to PE foam, making it ideal for pet beds that require enhanced comfort and support. PE foam is denser and more rigid, providing durability and resistance to impact but less softness for pets seeking plush resting surfaces. Choosing between EVA and PE foam depends on the balance desired between comfort and firmness in pet products.

Table of Comparison

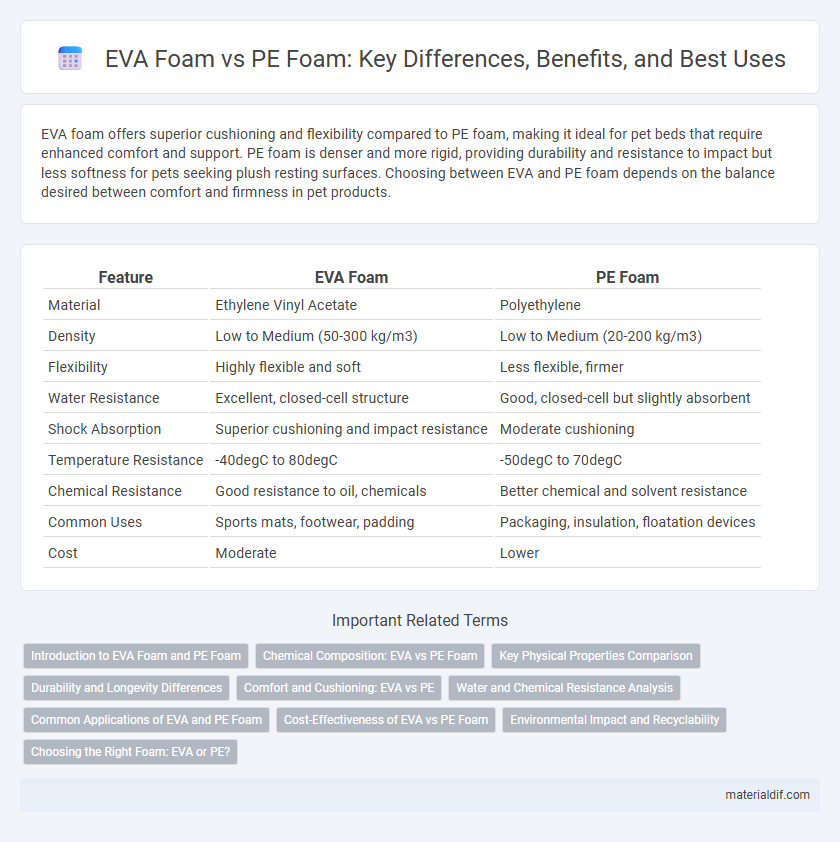

| Feature | EVA Foam | PE Foam |

|---|---|---|

| Material | Ethylene Vinyl Acetate | Polyethylene |

| Density | Low to Medium (50-300 kg/m3) | Low to Medium (20-200 kg/m3) |

| Flexibility | Highly flexible and soft | Less flexible, firmer |

| Water Resistance | Excellent, closed-cell structure | Good, closed-cell but slightly absorbent |

| Shock Absorption | Superior cushioning and impact resistance | Moderate cushioning |

| Temperature Resistance | -40degC to 80degC | -50degC to 70degC |

| Chemical Resistance | Good resistance to oil, chemicals | Better chemical and solvent resistance |

| Common Uses | Sports mats, footwear, padding | Packaging, insulation, floatation devices |

| Cost | Moderate | Lower |

Introduction to EVA Foam and PE Foam

EVA foam (ethylene-vinyl acetate) is a soft, flexible material known for its excellent shock absorption, water resistance, and durability, making it ideal for sports equipment and footwear. PE foam (polyethylene foam) offers a lightweight, closed-cell structure with high impact cushioning, frequently used in packaging, insulation, and flotation devices. Both foams provide effective cushioning but differ in density, resilience, and water resistance, which influences their application suitability.

Chemical Composition: EVA vs PE Foam

EVA foam is primarily composed of ethylene-vinyl acetate copolymer, combining flexibility and softness due to vinyl acetate content ranging typically between 10-40%, which enhances elasticity and stress-crack resistance. PE foam, made from polyethylene polymer chains, offers higher density and rigidity with excellent moisture resistance and chemical stability, attributed to its semi-crystalline structure. The distinct chemical compositions result in EVA foam's superior cushioning and shock absorption, while PE foam excels in insulation and durability for industrial applications.

Key Physical Properties Comparison

EVA foam offers higher elasticity and resilience with a Shore A hardness range between 15-70, making it ideal for cushioning and impact absorption applications. PE foam typically has lower density and stiffness but excels in thermal insulation and buoyancy due to its closed-cell structure and lower moisture absorption. Both foams vary significantly in tensile strength and compression set, with EVA often providing superior durability and flexibility compared to the more rigid and lightweight PE foam.

Durability and Longevity Differences

EVA foam offers superior durability and longevity compared to PE foam due to its higher resistance to cracking, UV exposure, and chemical degradation. PE foam tends to compress and break down faster under continuous mechanical stress and environmental exposure. The closed-cell structure of EVA foam enhances its resilience, making it ideal for applications requiring extended wear and impact resistance.

Comfort and Cushioning: EVA vs PE

EVA foam offers superior comfort and cushioning due to its softer, more flexible structure, making it ideal for footwear midsoles and sports equipment. PE foam is denser and provides firmer support with less elasticity, which suits applications requiring durability and impact resistance. The choice between EVA and PE foam depends on prioritizing either enhanced comfort or structural support.

Water and Chemical Resistance Analysis

EVA foam exhibits superior water resistance due to its closed-cell structure, preventing water absorption and maintaining buoyancy in wet environments. In contrast, PE foam offers moderate water resistance but tends to absorb chemicals like oils and solvents, causing degradation over time. Chemical resistance tests reveal that EVA foam withstands a broader range of acids and alkalis, making it ideal for applications requiring enhanced durability against harsh substances.

Common Applications of EVA and PE Foam

EVA foam is frequently used in sports equipment, footwear insoles, and protective padding due to its excellent shock absorption and flexibility. PE foam finds common applications in packaging, insulation, and flotation devices because of its lightweight and closed-cell structure that provides water resistance. Both materials are chosen for their unique properties tailored to specific industry needs, optimizing performance and durability.

Cost-Effectiveness of EVA vs PE Foam

EVA foam generally offers higher durability and flexibility but comes at a higher price point compared to PE foam, making it less cost-effective for large-scale or budget-sensitive projects. PE foam is more affordable with decent cushioning properties, providing an economical solution for packaging, insulation, and padding applications. Evaluating specific use cases, PE foam often delivers better cost-effectiveness in terms of price-to-performance ratio in industries prioritizing budget constraints.

Environmental Impact and Recyclability

EVA foam is derived from ethylene-vinyl acetate copolymers, offering moderate recyclability and relatively low environmental toxicity compared to petroleum-based materials. PE foam, made from polyethylene, is widely recyclable through established plastic recycling streams but poses higher environmental risks due to its non-biodegradable nature and potential microplastic pollution. Both foams require improved recycling infrastructure to minimize landfill accumulation and reduce their ecological footprint.

Choosing the Right Foam: EVA or PE?

EVA foam offers superior elasticity, shock absorption, and durability, making it ideal for sports equipment and footwear. PE foam excels in lightweight cushioning and thermal insulation, commonly used in packaging and construction. Selecting the right foam depends on application needs such as flexibility, impact resistance, and environmental exposure.

EVA foam vs PE foam Infographic

materialdif.com

materialdif.com