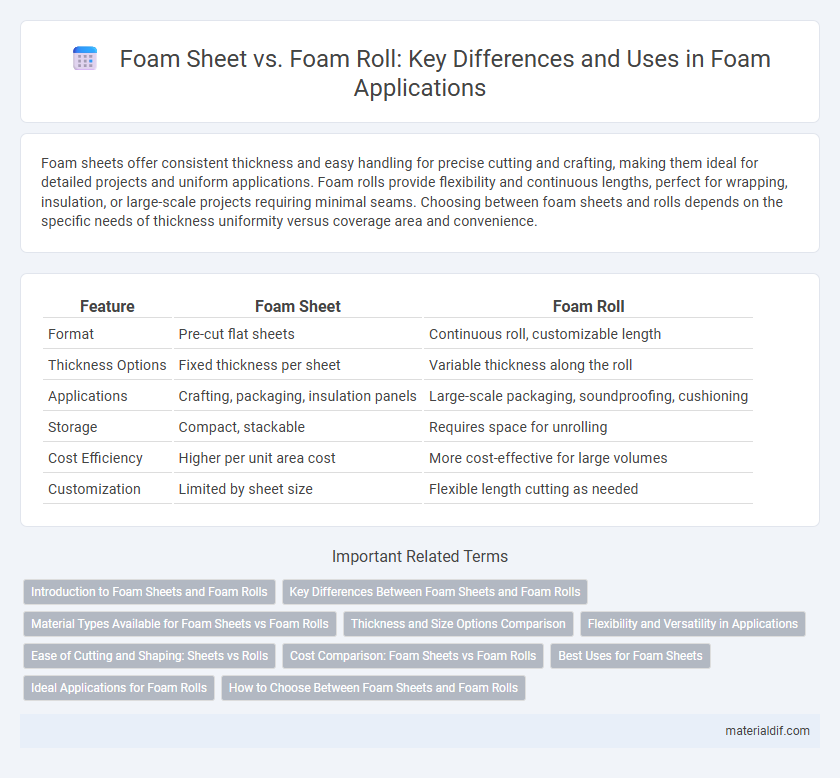

Foam sheets offer consistent thickness and easy handling for precise cutting and crafting, making them ideal for detailed projects and uniform applications. Foam rolls provide flexibility and continuous lengths, perfect for wrapping, insulation, or large-scale projects requiring minimal seams. Choosing between foam sheets and rolls depends on the specific needs of thickness uniformity versus coverage area and convenience.

Table of Comparison

| Feature | Foam Sheet | Foam Roll |

|---|---|---|

| Format | Pre-cut flat sheets | Continuous roll, customizable length |

| Thickness Options | Fixed thickness per sheet | Variable thickness along the roll |

| Applications | Crafting, packaging, insulation panels | Large-scale packaging, soundproofing, cushioning |

| Storage | Compact, stackable | Requires space for unrolling |

| Cost Efficiency | Higher per unit area cost | More cost-effective for large volumes |

| Customization | Limited by sheet size | Flexible length cutting as needed |

Introduction to Foam Sheets and Foam Rolls

Foam sheets and foam rolls are versatile materials commonly used for cushioning, insulation, and packaging applications. Foam sheets offer uniform thickness and easy handling, making them ideal for precise cuts and flat surface coverage, while foam rolls provide flexibility and continuous length, suitable for wrapping or large-scale projects. Selecting between foam sheets and foam rolls depends on the specific requirement for dimension control and installation convenience.

Key Differences Between Foam Sheets and Foam Rolls

Foam sheets offer precise dimensions and a uniform thickness, making them ideal for projects requiring exact measurements and flat surfaces. Foam rolls provide continuous length, allowing for seamless coverage in large areas and reducing waste through customizable cutting. The choice between foam sheets and foam rolls depends on the application's need for size consistency versus flexibility in length.

Material Types Available for Foam Sheets vs Foam Rolls

Foam sheets and foam rolls come in various material types, including polyethylene, polyurethane, EVA, and PVC, each offering distinct properties like cushioning, insulation, and durability. Foam sheets are typically available in rigid or semi-rigid forms, ideal for precision cutting and structural applications, while foam rolls are more flexible, suited for wrapping, padding, and continuous insulation uses. Material choice impacts factors such as density, compressibility, and moisture resistance, influencing whether a sheet or roll better meets project requirements.

Thickness and Size Options Comparison

Foam sheets offer precise thickness options ranging from 1/8 inch to 2 inches, available in large, uniform dimensions such as 24x36 inches, ideal for projects requiring flat, stable surfaces. Foam rolls provide versatility with thickness typically between 1/4 inch and 1 inch, available in continuous lengths up to 50 feet, allowing customization to specific size requirements without seams. The choice between foam sheet and roll depends on the application's need for consistent thickness or adaptable sizing for cutting and wrapping.

Flexibility and Versatility in Applications

Foam sheets offer structured flexibility ideal for consistent, flat surfaces, making them perfect for insulation, cushioning, and protective packaging. Foam rolls provide unmatched versatility in length and thickness, allowing customization for wrapping irregular shapes, soundproofing, and craft projects. Selecting between foam sheets and rolls depends on the required application precision and adaptability.

Ease of Cutting and Shaping: Sheets vs Rolls

Foam sheets offer precise, straight edges that simplify cutting and shaping for detailed projects, making them ideal for tasks requiring accuracy and uniformity. Foam rolls provide flexibility and continuous length, allowing for customized sizes but may require more effort to achieve clean cuts and consistent shapes. The choice between sheets and rolls depends on the specific precision needed and the ease of handling during the cutting process.

Cost Comparison: Foam Sheets vs Foam Rolls

Foam sheets generally offer a higher cost per unit area compared to foam rolls, making rolls more economical for large-scale or continuous projects. Foam rolls provide versatility in length and can reduce waste, while foam sheets are pre-cut and convenient for smaller, precise applications. Choosing between sheets and rolls depends on project size, budget constraints, and desired foam thickness uniformity.

Best Uses for Foam Sheets

Foam sheets are ideal for precise cutting and crafting applications, providing a firm and uniform surface perfect for model making, packaging, and insulation tasks. Their flat, rigid structure allows for easy customization in automotive padding, soundproofing panels, and medical cushioning, where consistent thickness and shape are critical. Foam rolls excel in large-scale wrapping and cushioning jobs but foam sheets remain the top choice for detailed projects requiring clean edges and specific dimensions.

Ideal Applications for Foam Rolls

Foam rolls are ideal for applications requiring continuous, customizable lengths of foam, such as cushioning in packaging, insulation in construction, or padding in automotive interiors. Their flexibility allows for easy cutting and shaping to fit irregular surfaces and large-scale projects. Foam rolls also provide a cost-effective solution for covering extensive areas without seams, enhancing durability and performance.

How to Choose Between Foam Sheets and Foam Rolls

Choosing between foam sheets and foam rolls depends on the project's size and shape requirements. Foam sheets provide precise, uniform thickness ideal for cutting custom shapes and smaller tasks, while foam rolls offer continuous lengths suitable for large-scale insulation or cushioning applications. Consider density, thickness, and ease of handling to match the foam type with specific use cases such as packaging, upholstery, or soundproofing.

Foam sheet vs Foam roll Infographic

materialdif.com

materialdif.com