PVC foam offers superior rigidity and chemical resistance compared to PE foam, making it ideal for applications requiring structural strength and durability. PE foam provides excellent flexibility and cushioning properties, suited for packaging and insulation where shock absorption is critical. Both materials have distinct advantages, with PVC foam favored for construction and automotive uses, while PE foam excels in protective and thermal applications.

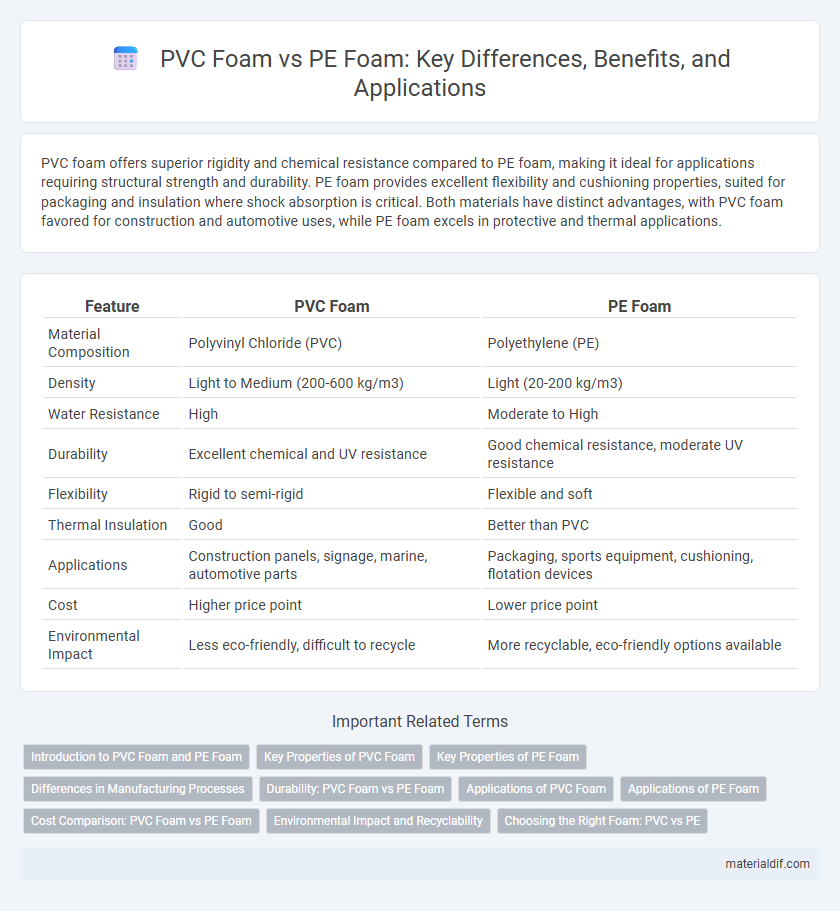

Table of Comparison

| Feature | PVC Foam | PE Foam |

|---|---|---|

| Material Composition | Polyvinyl Chloride (PVC) | Polyethylene (PE) |

| Density | Light to Medium (200-600 kg/m3) | Light (20-200 kg/m3) |

| Water Resistance | High | Moderate to High |

| Durability | Excellent chemical and UV resistance | Good chemical resistance, moderate UV resistance |

| Flexibility | Rigid to semi-rigid | Flexible and soft |

| Thermal Insulation | Good | Better than PVC |

| Applications | Construction panels, signage, marine, automotive parts | Packaging, sports equipment, cushioning, flotation devices |

| Cost | Higher price point | Lower price point |

| Environmental Impact | Less eco-friendly, difficult to recycle | More recyclable, eco-friendly options available |

Introduction to PVC Foam and PE Foam

PVC foam is a lightweight, rigid material known for its excellent chemical resistance, durability, and fire retardant properties, commonly used in construction, signage, and automotive applications. PE foam, or polyethylene foam, offers superior flexibility, impact absorption, and water resistance, making it ideal for packaging, insulation, and cushioning products. Both foams have distinct molecular structures influencing their performance, with PVC being a closed-cell foam offering rigidity, while PE foam's cellular structure provides greater elasticity and shock absorption.

Key Properties of PVC Foam

PVC foam demonstrates superior rigidity, excellent chemical resistance, and high durability compared to PE foam, making it ideal for structural applications and outdoor use. It features enhanced fire retardancy and UV stability, ensuring longevity under harsh environmental conditions. Its closed-cell structure provides good insulation and low water absorption, contributing to excellent mechanical strength and lightweight characteristics.

Key Properties of PE Foam

PE foam is characterized by its excellent density range, typically between 20 to 60 kg/m3, providing superior cushioning and shock absorption compared to PVC foam. It exhibits high resilience, low moisture absorption, and excellent chemical resistance, making it ideal for marine, automotive, and packaging applications. Its closed-cell structure also enhances thermal insulation and buoyancy properties, setting it apart from the denser, less flexible PVC foam.

Differences in Manufacturing Processes

PVC foam is produced through a chemical blowing process involving the mixing of polyvinyl chloride resin with blowing agents and stabilizers, followed by heating and molding to create a rigid, closed-cell structure. PE foam is typically manufactured using physical blowing agents such as gas or steam in an extrusion or molding process, resulting in a lightweight, flexible, and open or closed-cell structure depending on the specific method. The key differences lie in PVC foam's chemical blowing approach and rigid composition versus PE foam's physical blowing technique and versatile flexibility.

Durability: PVC Foam vs PE Foam

PVC foam exhibits superior durability compared to PE foam due to its higher resistance to abrasion, impact, and chemical exposure. Its closed-cell structure enhances strength and prevents water absorption, making it ideal for outdoor and marine applications. PE foam, while lightweight and flexible, tends to degrade faster under prolonged UV exposure and mechanical stress.

Applications of PVC Foam

PVC foam is widely used in marine, automotive, and construction industries due to its excellent rigidity, chemical resistance, and durability. It is ideal for outdoor applications such as signage, wall panels, and boat interiors where weather resistance and structural strength are crucial. Compared to PE foam, PVC foam provides superior dimensional stability and fire retardancy, making it preferred for high-performance applications.

Applications of PE Foam

PE foam is widely used in packaging, cushioning, and insulation due to its excellent shock absorption and moisture resistance properties. It is commonly applied in sports equipment padding, automotive interiors, and flotation devices where lightweight and durability are critical. PE foam's chemical resistance and flexibility make it suitable for sealing, gaskets, and protective cases across various industries.

Cost Comparison: PVC Foam vs PE Foam

PVC foam generally costs more than PE foam due to its higher density and enhanced durability, making it suitable for applications requiring structural strength. PE foam is more economical, offering lightweight cushioning and insulation properties, ideal for packaging and thermal protection. The price difference reflects their material composition and performance, guiding users based on budget and functional needs.

Environmental Impact and Recyclability

PVC foam generates significant environmental concerns due to its chlorine content, which can release harmful dioxins during production and disposal processes. PE foam offers better recyclability, being a non-chlorinated thermoplastic that can be melted and reprocessed multiple times with lower environmental risks. The biodegradability of PE foam is limited but still preferable to the persistent environmental pollutants associated with PVC foam.

Choosing the Right Foam: PVC vs PE

PVC foam offers higher rigidity, excellent chemical resistance, and better durability, making it ideal for structural applications and outdoor use. PE foam provides superior cushioning, flexibility, and impact absorption, preferred for packaging, insulation, and sports equipment. Selecting between PVC and PE foam depends on the required balance of strength versus softness and environmental exposure.

PVC Foam vs PE Foam Infographic

materialdif.com

materialdif.com