Polyolefin foam offers superior chemical resistance, excellent moisture barrier properties, and enhanced durability compared to polyurethane foam, making it ideal for outdoor pet products and applications requiring long-term exposure to environmental elements. Polyurethane foam provides better cushioning and flexibility, which is beneficial for pet bedding and comfort-focused products but is more prone to degradation from moisture and UV exposure. Choosing between polyolefin and polyurethane foam depends on balancing durability and comfort based on the specific needs of pet applications.

Table of Comparison

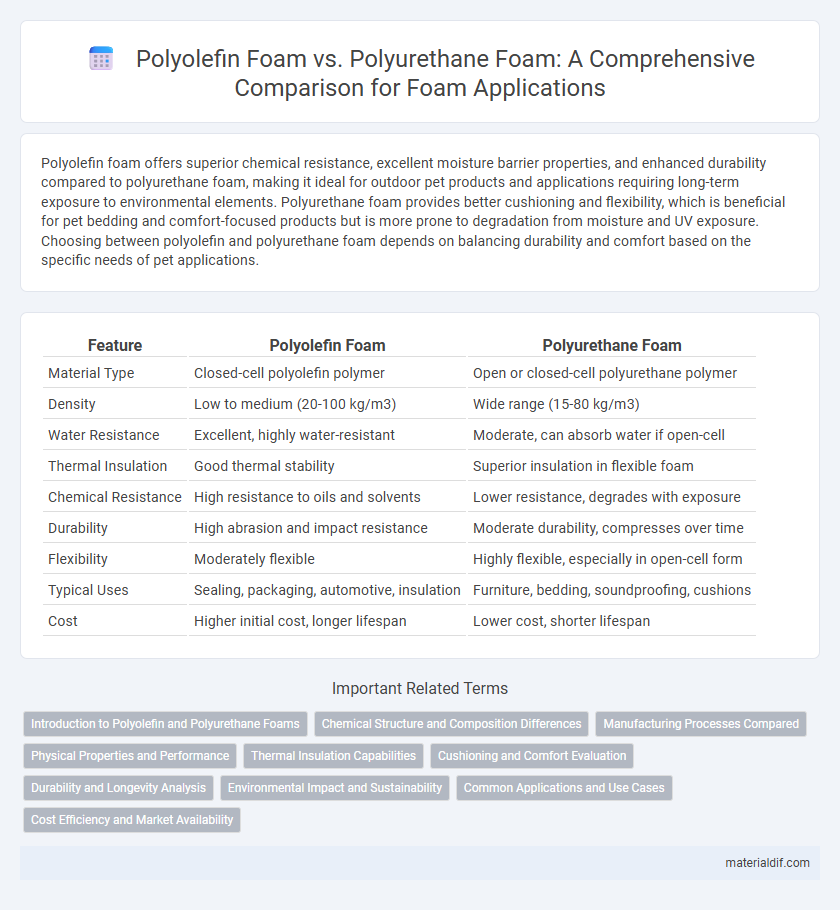

| Feature | Polyolefin Foam | Polyurethane Foam |

|---|---|---|

| Material Type | Closed-cell polyolefin polymer | Open or closed-cell polyurethane polymer |

| Density | Low to medium (20-100 kg/m3) | Wide range (15-80 kg/m3) |

| Water Resistance | Excellent, highly water-resistant | Moderate, can absorb water if open-cell |

| Thermal Insulation | Good thermal stability | Superior insulation in flexible foam |

| Chemical Resistance | High resistance to oils and solvents | Lower resistance, degrades with exposure |

| Durability | High abrasion and impact resistance | Moderate durability, compresses over time |

| Flexibility | Moderately flexible | Highly flexible, especially in open-cell form |

| Typical Uses | Sealing, packaging, automotive, insulation | Furniture, bedding, soundproofing, cushions |

| Cost | Higher initial cost, longer lifespan | Lower cost, shorter lifespan |

Introduction to Polyolefin and Polyurethane Foams

Polyolefin foam, derived from polymers such as polyethylene and polypropylene, offers lightweight, closed-cell structure with excellent chemical resistance and durability ideal for packaging, insulation, and automotive applications. Polyurethane foam, composed of polymers formed by reacting polyols and isocyanates, provides versatile open or closed-cell structures featuring superior cushioning, thermal insulation, and flexibility widely used in furniture, bedding, and soundproofing. Both foams serve diverse industrial needs but differ significantly in mechanical properties, density, and resistance to environmental factors.

Chemical Structure and Composition Differences

Polyolefin foam is primarily composed of polyethylene or polypropylene polymers, characterized by a simple hydrocarbon backbone with repeating ethylene or propylene units, making it chemically inert and resistant to moisture and chemicals. In contrast, polyurethane foam consists of urethane linkages formed by the reaction of polyols and isocyanates, resulting in a more complex polymer network with urethane bonds that contribute to its flexibility and cushioning properties. These structural and compositional differences impact their thermal stability, chemical resistance, and application suitability across various industries.

Manufacturing Processes Compared

Polyolefin foam is produced through a physical or chemical blowing agent that expands the polymer, typically using extrusion or bead sintering methods, resulting in a closed-cell structure with high durability and moisture resistance. Polyurethane foam manufacturing involves a chemical reaction between isocyanates and polyols, often created through batch or continuous processes that yield either flexible or rigid foam with tunable properties. The manufacturing of polyolefin foam emphasizes energy efficiency and recyclability, while polyurethane foam production offers greater customization of density and resilience but involves more complex chemical handling.

Physical Properties and Performance

Polyolefin foam offers superior chemical resistance, higher tensile strength, and lower density compared to polyurethane foam, making it ideal for applications requiring durability and lightweight properties. Polyurethane foam provides excellent cushioning, higher compressive strength, and better thermal insulation due to its open-cell structure, suitable for comfort and shock absorption uses. In terms of water absorption, polyolefin foam exhibits minimal moisture uptake, while polyurethane foam tends to absorb more water, affecting long-term performance in wet environments.

Thermal Insulation Capabilities

Polyolefin foam exhibits superior thermal insulation properties due to its closed-cell structure, which effectively minimizes heat transfer by trapping air within its cells. Polyurethane foam, while also providing good insulation, tends to have an open-cell structure that allows more heat conduction and reduces overall thermal resistance. In applications requiring high energy efficiency and moisture resistance, polyolefin foam is often preferred for maintaining consistent thermal performance.

Cushioning and Comfort Evaluation

Polyolefin foam offers superior cushioning with enhanced resilience and durability, making it ideal for applications requiring consistent support under repeated compression. Polyurethane foam provides excellent initial comfort due to its softer, more flexible structure but tends to lose cushioning effectiveness over time with prolonged use. Evaluations highlight polyolefin foam's longer lifespan and better shock absorption, whereas polyurethane foam excels in immediate comfort and adaptability to body contours.

Durability and Longevity Analysis

Polyolefin foam exhibits superior durability compared to polyurethane foam due to its higher resistance to chemicals, moisture, and UV exposure, making it ideal for outdoor and industrial applications. Polyurethane foam tends to degrade faster under prolonged stress and environmental factors, leading to reduced longevity in high-demand uses. The closed-cell structure of polyolefin foam enhances its lifespan by preventing water absorption, whereas polyurethane's open-cell structure often results in quicker wear and tear.

Environmental Impact and Sustainability

Polyolefin foam demonstrates superior environmental sustainability due to its recyclability and lower toxicity compared to polyurethane foam, which often relies on petroleum-based chemicals and releases harmful volatile organic compounds (VOCs) during degradation. The closed-cell structure of polyolefin foam reduces greenhouse gas emissions by enhancing insulation efficiency, whereas polyurethane foam's production and disposal can contribute to significant environmental pollution. Polyolefin materials are increasingly favored in eco-friendly applications for their reduced carbon footprint and greater potential for circular economy integration.

Common Applications and Use Cases

Polyolefin foam is widely used in packaging, automotive components, and insulation due to its lightweight, chemical resistance, and excellent cushioning properties. Polyurethane foam commonly serves in furniture, mattresses, and thermal insulation because of its superior comfort, flexibility, and thermal performance. Both foams provide effective noise reduction and impact absorption but are chosen based on specific application requirements such as durability and environmental resistance.

Cost Efficiency and Market Availability

Polyolefin foam offers superior cost efficiency due to its lower raw material and production costs compared to polyurethane foam, making it a preferred choice for budget-sensitive applications. Its widespread market availability stems from the abundant supply of polyolefin resins and established manufacturing infrastructure, ensuring consistent product accessibility. Polyurethane foam, while versatile and high-performing, generally commands higher prices and faces more complex supply chains, affecting its cost-effectiveness in mass-market use.

Polyolefin foam vs Polyurethane foam Infographic

materialdif.com

materialdif.com