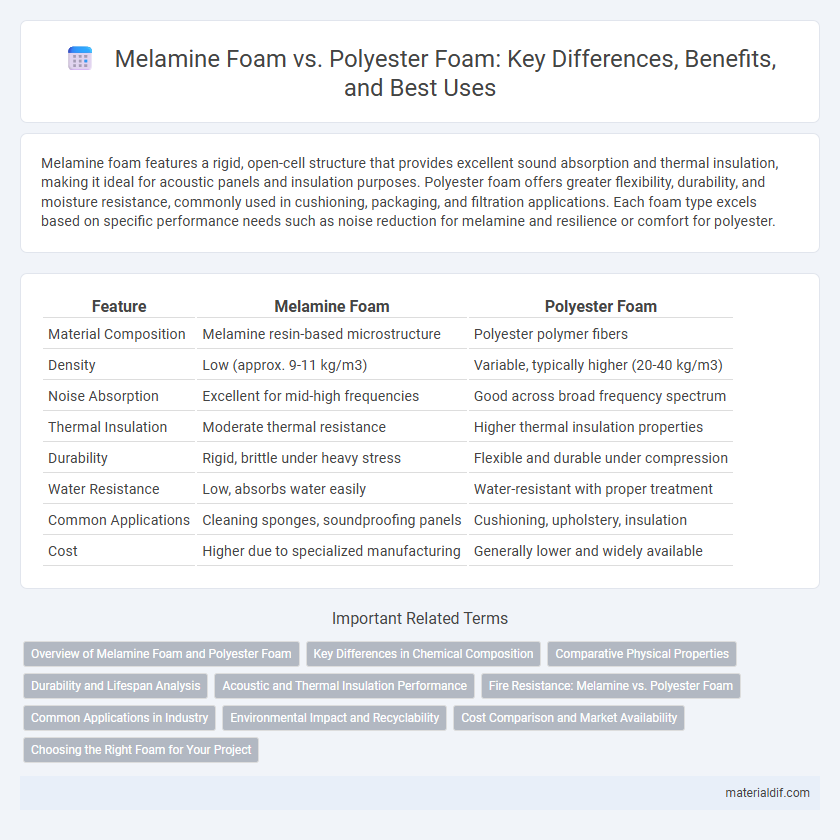

Melamine foam features a rigid, open-cell structure that provides excellent sound absorption and thermal insulation, making it ideal for acoustic panels and insulation purposes. Polyester foam offers greater flexibility, durability, and moisture resistance, commonly used in cushioning, packaging, and filtration applications. Each foam type excels based on specific performance needs such as noise reduction for melamine and resilience or comfort for polyester.

Table of Comparison

| Feature | Melamine Foam | Polyester Foam |

|---|---|---|

| Material Composition | Melamine resin-based microstructure | Polyester polymer fibers |

| Density | Low (approx. 9-11 kg/m3) | Variable, typically higher (20-40 kg/m3) |

| Noise Absorption | Excellent for mid-high frequencies | Good across broad frequency spectrum |

| Thermal Insulation | Moderate thermal resistance | Higher thermal insulation properties |

| Durability | Rigid, brittle under heavy stress | Flexible and durable under compression |

| Water Resistance | Low, absorbs water easily | Water-resistant with proper treatment |

| Common Applications | Cleaning sponges, soundproofing panels | Cushioning, upholstery, insulation |

| Cost | Higher due to specialized manufacturing | Generally lower and widely available |

Overview of Melamine Foam and Polyester Foam

Melamine foam features a rigid, open-cell structure offering excellent sound absorption, thermal insulation, and fire resistance, making it ideal for acoustic panels and insulation applications. Polyester foam is a versatile, closed-cell material known for its durability, flexibility, and moisture resistance, commonly used in cushioning, packaging, and filtration. Both foams differ significantly in texture, performance, and cost, with melamine foam excelling in fire retardancy and polyester foam favored for mechanical resilience.

Key Differences in Chemical Composition

Melamine foam is composed of a thermosetting melamine-formaldehyde polymer, offering a rigid, open-cell structure ideal for heat resistance and sound absorption. Polyester foam consists of thermoplastic polyester polymers, characterized by a flexible, closed-cell structure that excels in cushioning and insulation. The key difference lies in melamine's aromatic triazine ring structure versus polyester's ester linkages, impacting durability and environmental resistance.

Comparative Physical Properties

Melamine foam exhibits superior fire resistance and thermal insulation compared to polyester foam, making it ideal for high-temperature applications. Polyester foam is denser and generally provides better cushioning and sound absorption due to its closed-cell structure. Both foams differ significantly in moisture resistance, with melamine foam offering better moisture permeability while polyester foam is more water-resistant.

Durability and Lifespan Analysis

Melamine foam exhibits superior durability compared to polyester foam due to its rigid open-cell structure, which resists compression and maintains shape over extended use. The lifespan of melamine foam can extend up to several years in applications such as soundproofing and cleaning, whereas polyester foam typically shows quicker degradation and loss of resilience under similar conditions. This longevity difference makes melamine foam particularly advantageous for high-performance industrial and household applications requiring sustained durability.

Acoustic and Thermal Insulation Performance

Melamine foam provides superior acoustic insulation due to its open-cell structure that effectively absorbs sound waves, reducing noise levels in various environments. Polyester foam offers moderate thermal insulation but lacks the same level of sound absorption efficiency as melamine foam. For applications requiring enhanced noise control and thermal resistance, melamine foam is generally preferred over polyester foam.

Fire Resistance: Melamine vs. Polyester Foam

Melamine foam exhibits superior fire resistance compared to polyester foam, as it is inherently flame-retardant and does not melt when exposed to high temperatures. Polyester foam, on the other hand, is highly flammable, tends to melt and release toxic fumes during combustion. This makes melamine foam the preferred choice in applications requiring enhanced fire safety and compliance with stringent fire regulations.

Common Applications in Industry

Melamine foam is widely used in soundproofing, thermal insulation, and cleaning products due to its open-cell structure and fire-resistant properties. Polyester foam finds common applications in packaging, cushioning, and automotive interiors, valued for its durability and elasticity. Both foams are essential in industries requiring lightweight materials with specific acoustic and protective characteristics.

Environmental Impact and Recyclability

Melamine foam, known for its lightweight and effective sound absorption, poses environmental challenges due to its non-biodegradable chemical composition and limited recycling options, often resulting in landfill accumulation. Polyester foam offers better recyclability through established methods like mechanical shredding and reprocessing, reducing waste and environmental footprint. Choosing polyester foam supports circular economy principles, while melamine foam's persistence in ecosystems raises concerns about long-term environmental impact.

Cost Comparison and Market Availability

Melamine foam generally costs more than polyester foam due to its specialized manufacturing process and enhanced fire-retardant properties, making it a premium choice in applications requiring superior sound absorption and thermal insulation. Polyester foam is widely available and more affordable, benefiting from large-scale production and versatile use in cushioning, packaging, and filtration industries. Market availability favors polyester foam due to its lower cost and broad application range, while melamine foam occupies niche markets with higher performance demands despite its limited suppliers.

Choosing the Right Foam for Your Project

Melamine foam offers superior sound absorption and flame resistance, making it ideal for acoustic insulation and fire-safe applications. Polyester foam provides higher durability and flexibility, suitable for cushioning, packaging, and insulation where resilience is key. Selecting between melamine and polyester foam depends on project requirements such as fire resistance, acoustic performance, and mechanical strength.

Melamine foam vs Polyester foam Infographic

materialdif.com

materialdif.com