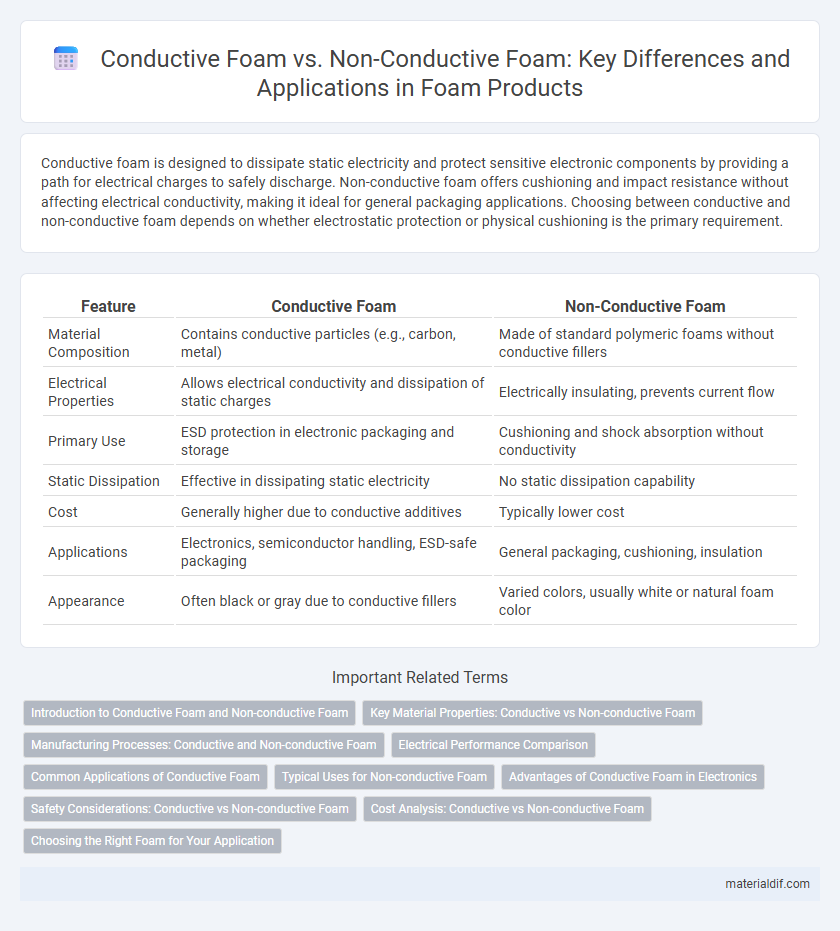

Conductive foam is designed to dissipate static electricity and protect sensitive electronic components by providing a path for electrical charges to safely discharge. Non-conductive foam offers cushioning and impact resistance without affecting electrical conductivity, making it ideal for general packaging applications. Choosing between conductive and non-conductive foam depends on whether electrostatic protection or physical cushioning is the primary requirement.

Table of Comparison

| Feature | Conductive Foam | Non-Conductive Foam |

|---|---|---|

| Material Composition | Contains conductive particles (e.g., carbon, metal) | Made of standard polymeric foams without conductive fillers |

| Electrical Properties | Allows electrical conductivity and dissipation of static charges | Electrically insulating, prevents current flow |

| Primary Use | ESD protection in electronic packaging and storage | Cushioning and shock absorption without conductivity |

| Static Dissipation | Effective in dissipating static electricity | No static dissipation capability |

| Cost | Generally higher due to conductive additives | Typically lower cost |

| Applications | Electronics, semiconductor handling, ESD-safe packaging | General packaging, cushioning, insulation |

| Appearance | Often black or gray due to conductive fillers | Varied colors, usually white or natural foam color |

Introduction to Conductive Foam and Non-conductive Foam

Conductive foam is a specialized material infused with conductive particles, enabling it to dissipate static electricity and protect sensitive electronic components from electrostatic discharge (ESD). Non-conductive foam, in contrast, lacks conductive elements and primarily serves as cushioning or insulation without offering ESD protection. Understanding the distinction between conductive and non-conductive foam is crucial for applications requiring static control versus those needing only mechanical cushioning.

Key Material Properties: Conductive vs Non-conductive Foam

Conductive foam contains metal particles or carbon additives that enable electrical conductivity, making it ideal for static discharge protection and shielding electronic components from electromagnetic interference (EMI). Non-conductive foam is made from purely insulating materials such as polyurethane or polyethylene, providing effective cushioning and moisture resistance without allowing electrical current flow. While conductive foam balances conductivity with cushioning, non-conductive foam emphasizes dielectric strength and impact absorption without compromising electrical isolation.

Manufacturing Processes: Conductive and Non-conductive Foam

Conductive foam is manufactured by incorporating carbon or metal particles into the polymer matrix, enabling electrical conductivity suitable for shielding and grounding applications. Non-conductive foam is produced using standard polymer foaming techniques without conductive additives, resulting in insulating properties ideal for cushioning and packaging. Manufacturing processes for conductive foam require precise control over particle dispersion to ensure consistent conductivity, while non-conductive foam emphasizes uniform cell structure for optimal mechanical performance.

Electrical Performance Comparison

Conductive foam exhibits low electrical resistance, providing reliable pathways for static charge dissipation in electronic packaging and ESD protection applications. Non-conductive foam, characterized by high electrical insulation properties, prevents current flow and is used primarily for cushioning without affecting electrical signals. The choice between conductive and non-conductive foam depends on specific electrical performance needs, including grounding requirements and signal integrity in sensitive electronic components.

Common Applications of Conductive Foam

Conductive foam is widely used in electronic packaging and electrostatic discharge (ESD) protection, where it safeguards sensitive components such as microchips and circuit boards during shipping and handling. Its ability to dissipate static electricity makes it essential in semiconductor manufacturing, assembly, and storage environments. Common applications also include shielding in aerospace and military electronics, ensuring reliable performance by preventing electrostatic damage.

Typical Uses for Non-conductive Foam

Non-conductive foam is extensively used for cushioning and protecting sensitive electronic components against static discharge and mechanical damage during shipping and assembly. It is ideal for packaging delicate devices such as semiconductors, circuit boards, and medical equipment that require insulation from electrical currents. Its excellent dielectric properties and shock absorption capabilities make it a preferred choice in electronics manufacturing and precision instrumentation industries.

Advantages of Conductive Foam in Electronics

Conductive foam offers superior static discharge protection by effectively dissipating electrostatic charges, reducing the risk of damage to sensitive electronic components. It enhances shielding against electromagnetic interference (EMI), ensuring signal integrity and improved device performance. Unlike non-conductive foam, conductive foam provides grounding capabilities, making it essential for packaging, handling, and storing electrostatic-sensitive devices (ESDs).

Safety Considerations: Conductive vs Non-conductive Foam

Conductive foam dissipates static electricity by allowing electrical charges to flow through its material, reducing the risk of electrostatic discharge (ESD) damage in sensitive electronic components. Non-conductive foam, while providing cushioning and insulation, does not prevent static buildup, potentially posing a higher ESD risk during handling and storage. Selecting conductive foam enhances safety in environments where static-sensitive devices require protection from electrostatic discharge hazards.

Cost Analysis: Conductive vs Non-conductive Foam

Conductive foam typically incurs higher costs due to its specialized materials and manufacturing processes designed to shield against electromagnetic interference (EMI). Non-conductive foam, being more common and simpler in composition, offers a cost-effective solution for cushioning and packing without EMI protection. Evaluating overall expenses involves considering the need for EMI shielding, as conductive foam's premium price is justified in sensitive electronic applications where preventing signal interference is critical.

Choosing the Right Foam for Your Application

Conductive foam is specifically engineered with carbon or metal particles to provide electrical conductivity, making it ideal for protecting sensitive electronic components from static discharge. Non-conductive foam, composed of standard polymers like polyurethane, offers cushioning and shock absorption without affecting electrical properties, suitable for general packaging and insulation needs. Selecting the right foam depends on application requirements such as electrostatic discharge (ESD) protection, mechanical cushioning, and environmental factors.

Conductive foam vs Non-conductive foam Infographic

materialdif.com

materialdif.com