XPS foam offers superior moisture resistance and higher compressive strength compared to EPS foam, making it ideal for applications requiring durability and insulation performance. EPS foam is more cost-effective and provides good thermal insulation but is less dense and more susceptible to water absorption. Choosing between XPS and EPS foam depends on budget constraints and specific project requirements such as moisture exposure and load-bearing needs.

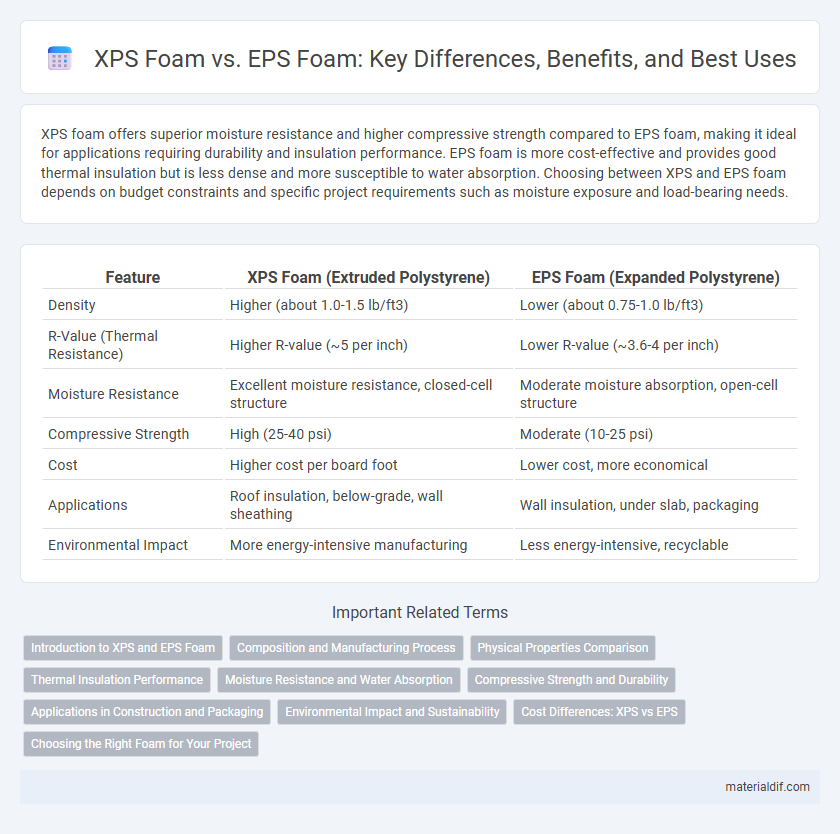

Table of Comparison

| Feature | XPS Foam (Extruded Polystyrene) | EPS Foam (Expanded Polystyrene) |

|---|---|---|

| Density | Higher (about 1.0-1.5 lb/ft3) | Lower (about 0.75-1.0 lb/ft3) |

| R-Value (Thermal Resistance) | Higher R-value (~5 per inch) | Lower R-value (~3.6-4 per inch) |

| Moisture Resistance | Excellent moisture resistance, closed-cell structure | Moderate moisture absorption, open-cell structure |

| Compressive Strength | High (25-40 psi) | Moderate (10-25 psi) |

| Cost | Higher cost per board foot | Lower cost, more economical |

| Applications | Roof insulation, below-grade, wall sheathing | Wall insulation, under slab, packaging |

| Environmental Impact | More energy-intensive manufacturing | Less energy-intensive, recyclable |

Introduction to XPS and EPS Foam

XPS (Extruded Polystyrene) foam is a rigid insulation material featuring a closed-cell structure that provides high compressive strength and excellent moisture resistance, ideal for use in foundations, roofs, and walls. EPS (Expanded Polystyrene) foam consists of expanded beads fused together, offering a lightweight, cost-effective solution with good thermal insulation but lower moisture resistance compared to XPS. Both XPS and EPS foam are widely used in construction, with XPS favored for durability and moisture barrier properties, while EPS is preferred for versatility and affordability.

Composition and Manufacturing Process

XPS foam is made from extruded polystyrene beads melted together through an extrusion process, producing a closed-cell structure with consistent density and moisture resistance. EPS foam consists of expanded polystyrene beads fused using steam molding, resulting in a lightweight, porous material with a more open-cell structure. The extrusion manufacturing of XPS enhances thermal insulation and compressive strength compared to the bead expansion method used for EPS.

Physical Properties Comparison

XPS foam exhibits higher compressive strength, typically around 20-40 psi, compared to EPS foam's 10-15 psi, making it more suitable for load-bearing applications. The closed-cell structure of XPS results in lower water absorption and better moisture resistance, while EPS's open-cell formation makes it more prone to water infiltration. Thermal conductivity values for XPS range from 0.029 to 0.034 W/m*K, providing more consistent insulation performance than EPS, which generally ranges from 0.035 to 0.045 W/m*K.

Thermal Insulation Performance

XPS foam offers superior thermal insulation performance with an R-value typically ranging from 5 to 5.5 per inch, providing better resistance to heat flow compared to EPS foam, which has an R-value around 3.6 to 4.2 per inch. The closed-cell structure of XPS foam enhances moisture resistance and long-term thermal efficiency, making it ideal for applications requiring high insulation and durability.

Moisture Resistance and Water Absorption

XPS foam exhibits superior moisture resistance compared to EPS foam due to its closed-cell structure, which significantly reduces water absorption rates. EPS foam tends to absorb more water because of its open-cell composition, leading to decreased insulation performance over time. High water absorption in EPS can result in structural degradation and diminished thermal efficiency in wet environments.

Compressive Strength and Durability

XPS foam typically offers higher compressive strength, ranging from 20 to 40 psi, compared to EPS foam's 10 to 25 psi, making it better suited for applications requiring load-bearing capacity. XPS foam also demonstrates superior durability due to its closed-cell structure, which provides enhanced moisture resistance and long-term performance in harsh environments. EPS foam's open-cell design results in lower durability and a higher susceptibility to water absorption and structural degradation over time.

Applications in Construction and Packaging

XPS foam offers superior moisture resistance and compressive strength, making it ideal for below-grade foundation insulation and roofing systems in construction. EPS foam excels in lightweight cushioning and shock absorption, widely used for protective packaging of electronics and fragile goods. Both materials provide thermal insulation but XPS's closed-cell structure enhances durability in harsh environments, while EPS's cost-effectiveness suits large-scale packagingXu Qiu .

Environmental Impact and Sustainability

XPS foam typically has a higher environmental impact than EPS foam due to its use of hydrofluorocarbon (HFC) blowing agents, which contribute to greenhouse gas emissions. EPS foam is more sustainable as it is manufactured with pentane blowing agents, has better recyclability, and lower embodied energy. Life cycle assessments show EPS foam's environmental footprint is generally smaller, making it the preferred choice for eco-friendly insulation solutions.

Cost Differences: XPS vs EPS

XPS foam typically costs more than EPS foam due to its higher manufacturing expenses and superior moisture resistance properties. EPS foam offers a more budget-friendly option with adequate thermal insulation but may require additional protective measures against water absorption. Choosing between XPS and EPS depends on project budget constraints and performance requirements in insulation applications.

Choosing the Right Foam for Your Project

XPS foam offers superior moisture resistance and higher compressive strength compared to EPS foam, making it ideal for applications requiring durability and insulation in damp environments. EPS foam provides excellent thermal insulation at a lower cost and is widely used for packaging and lightweight insulation needs. Evaluating project-specific factors such as budget, moisture exposure, and structural load helps determine whether XPS or EPS foam best suits your insulation and durability requirements.

XPS foam vs EPS foam Infographic

materialdif.com

materialdif.com