EVA foam offers excellent flexibility, durability, and resistance to UV radiation, making it ideal for outdoor applications and sports gear, while NBR foam provides superior oil and chemical resistance, commonly used in industrial seals and gaskets. EVA typically has a softer, lighter texture, enhancing comfort in footwear and cushioning, whereas NBR's denser structure ensures better mechanical strength and compression set resistance. Choosing between EVA and NBR foam depends on the specific needs for resilience, environmental exposure, and chemical tolerance in the intended application.

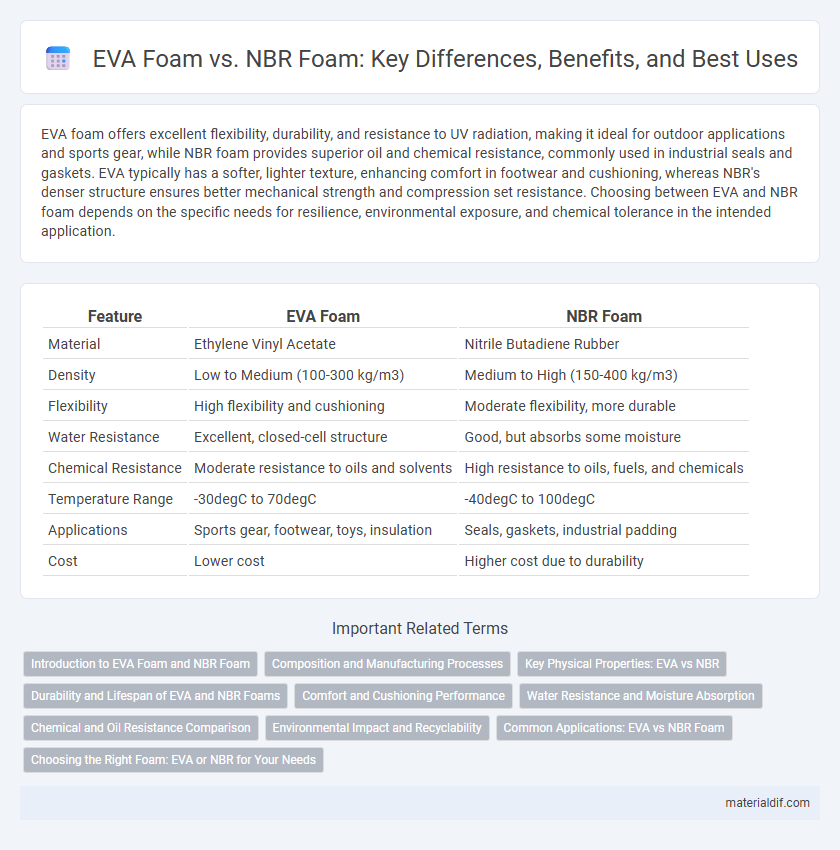

Table of Comparison

| Feature | EVA Foam | NBR Foam |

|---|---|---|

| Material | Ethylene Vinyl Acetate | Nitrile Butadiene Rubber |

| Density | Low to Medium (100-300 kg/m3) | Medium to High (150-400 kg/m3) |

| Flexibility | High flexibility and cushioning | Moderate flexibility, more durable |

| Water Resistance | Excellent, closed-cell structure | Good, but absorbs some moisture |

| Chemical Resistance | Moderate resistance to oils and solvents | High resistance to oils, fuels, and chemicals |

| Temperature Range | -30degC to 70degC | -40degC to 100degC |

| Applications | Sports gear, footwear, toys, insulation | Seals, gaskets, industrial padding |

| Cost | Lower cost | Higher cost due to durability |

Introduction to EVA Foam and NBR Foam

EVA foam, or ethylene vinyl acetate foam, is a lightweight, flexible material known for its excellent shock absorption and durability, commonly used in footwear, sports equipment, and padding. NBR foam, made from nitrile butadiene rubber, offers superior resistance to oils, fuels, and chemicals, making it ideal for industrial applications and protective gear. Both foams provide cushioning and insulation but differ significantly in chemical resistance and flexibility, influencing their suitability for various end uses.

Composition and Manufacturing Processes

EVA foam is composed of ethylene-vinyl acetate copolymers known for their flexibility and shock absorption, produced through gas injection or chemical blowing agent methods that create closed-cell structures. NBR foam, made from nitrile rubber polymers combining acrylonitrile and butadiene, is manufactured via vulcanization and foaming processes that yield enhanced oil and chemical resistance with open-cell or closed-cell configurations. The differing polymer compositions and curing techniques directly influence the mechanical properties and application suitability of EVA and NBR foams.

Key Physical Properties: EVA vs NBR

EVA foam exhibits higher flexibility, excellent impact absorption, and superior UV resistance, making it ideal for outdoor applications and footwear. NBR foam offers outstanding oil and chemical resistance along with greater durability in harsh industrial environments, thanks to its nitrile rubber composition. Both foams differ significantly in density and tensile strength, with EVA being lighter and more resilient, whereas NBR provides enhanced abrasion resistance and compression set stability.

Durability and Lifespan of EVA and NBR Foams

EVA foam offers superior durability compared to NBR foam, with enhanced resistance to cracking, tearing, and UV degradation, resulting in a longer lifespan under regular use. NBR foam, while flexible and oil-resistant, tends to deteriorate faster when exposed to environmental factors such as heat and ozone. EVA foam's structured cellular composition contributes to its extended durability, making it ideal for applications requiring long-term performance.

Comfort and Cushioning Performance

EVA foam offers superior comfort and cushioning due to its lightweight, flexible, and shock-absorbing properties, making it ideal for footwear and sports equipment. NBR foam provides excellent resilience and durability with higher resistance to oil and chemicals, but it tends to be denser and less flexible, impacting overall comfort. Choosing EVA foam enhances softness and energy return, while NBR foam excels in sustained compression, balancing cushioning performance with durability.

Water Resistance and Moisture Absorption

EVA foam exhibits superior water resistance due to its closed-cell structure, preventing water penetration and making it ideal for wet environments. NBR foam, while offering some water resistance, tends to absorb more moisture because of its open-cell composition, leading to potential degradation over time. This difference makes EVA foam preferable for applications requiring prolonged exposure to water and high humidity.

Chemical and Oil Resistance Comparison

EVA foam demonstrates superior chemical resistance, maintaining stability when exposed to acids, alkalis, and oils compared to NBR foam. NBR foam excels in oil resistance due to its nitrile butadiene rubber composition, making it ideal for environments with prolonged oil contact. Both foams offer varied performance in chemical and oil resistance, requiring selection based on specific exposure conditions.

Environmental Impact and Recyclability

EVA foam, derived from ethylene-vinyl acetate copolymer, exhibits moderate biodegradability and energy-efficient recycling compared to NBR foam, which is produced from nitrile rubber and poses greater challenges due to its synthetic nature and chemical resistance. NBR foam's environmental impact is heightened by its limited recyclability and reliance on petroleum-based raw materials, contributing to higher carbon emissions. Choosing EVA foam over NBR foam supports sustainability efforts by promoting easier recycling processes and reducing long-term ecological footprints.

Common Applications: EVA vs NBR Foam

EVA foam is widely used in sports equipment, footwear insoles, and packaging due to its lightweight, flexibility, and excellent shock absorption qualities. NBR foam excels in industrial sealing, gaskets, and protective padding applications because of its superior resistance to oils, fuels, and chemicals. Both foams serve critical roles in automotive interiors, with EVA favored for cushioning and NBR preferred for durability in harsh environments.

Choosing the Right Foam: EVA or NBR for Your Needs

EVA foam offers superior elasticity, lightweight properties, and excellent shock absorption, making it ideal for sports equipment and cushioning applications. NBR foam stands out with its excellent oil resistance, durability, and thermal insulation, suited for industrial seals and automotive gaskets. Selecting between EVA and NBR foam depends on factors like chemical exposure, temperature range, and flexibility requirements for your specific project.

EVA Foam vs NBR Foam Infographic

materialdif.com

materialdif.com