Spray foam offers superior air sealing and insulation by expanding to fill gaps and hard-to-reach areas, making it ideal for complex shapes and irregular spaces. Board foam provides consistent, rigid panels that are easier to install and offer a precise R-value per inch, suitable for walls and roofs with flat surfaces. Choosing between spray foam and board foam depends on the specific application requirements, budget, and desired thermal performance.

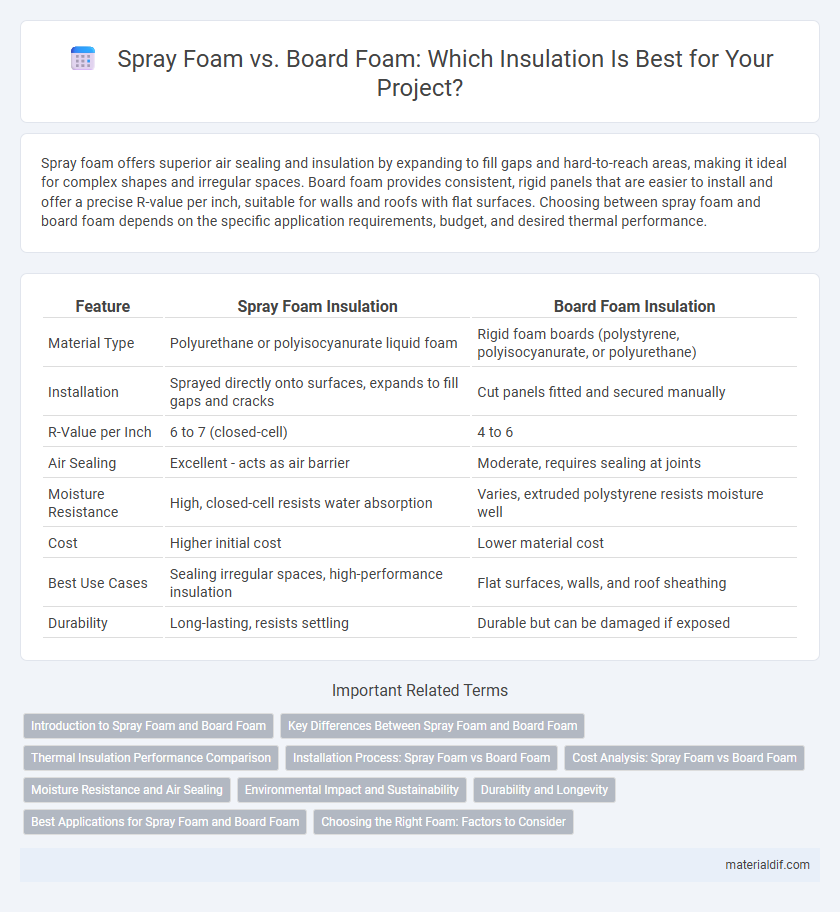

Table of Comparison

| Feature | Spray Foam Insulation | Board Foam Insulation |

|---|---|---|

| Material Type | Polyurethane or polyisocyanurate liquid foam | Rigid foam boards (polystyrene, polyisocyanurate, or polyurethane) |

| Installation | Sprayed directly onto surfaces, expands to fill gaps and cracks | Cut panels fitted and secured manually |

| R-Value per Inch | 6 to 7 (closed-cell) | 4 to 6 |

| Air Sealing | Excellent - acts as air barrier | Moderate, requires sealing at joints |

| Moisture Resistance | High, closed-cell resists water absorption | Varies, extruded polystyrene resists moisture well |

| Cost | Higher initial cost | Lower material cost |

| Best Use Cases | Sealing irregular spaces, high-performance insulation | Flat surfaces, walls, and roof sheathing |

| Durability | Long-lasting, resists settling | Durable but can be damaged if exposed |

Introduction to Spray Foam and Board Foam

Spray foam insulation is a polyurethane-based material that expands on application, filling gaps and creating an airtight seal for superior thermal performance and moisture resistance. Board foam insulation, typically made from polystyrene or polyisocyanurate, is rigid and provides consistent R-values while offering easy installation in flat surfaces and structural support. Both materials enhance energy efficiency, but spray foam excels in sealing irregular spaces, whereas board foam is preferred for uniform coverage and durability.

Key Differences Between Spray Foam and Board Foam

Spray foam insulation offers superior air sealing and higher R-values per inch compared to board foam, making it ideal for irregular spaces and comprehensive thermal protection. Board foam insulation, typically made from polystyrene or polyisocyanurate, provides consistent thickness and is easier to cut and install in flat, uniform areas. While spray foam expands to fill gaps and cracks, board foam's rigid panels offer enhanced structural reinforcement and moisture resistance.

Thermal Insulation Performance Comparison

Spray foam insulation offers superior thermal performance with an R-value ranging from 6 to 7 per inch, creating an airtight seal that minimizes thermal bridging and energy loss. Board foam insulation, typically with an R-value between 4 and 6 per inch depending on the type (XPS, EPS, or polyiso), provides consistent insulation but may require additional sealing to prevent air leaks. The enhanced expansion and adhesion properties of spray foam make it more effective in irregular spaces, improving overall energy efficiency compared to rigid foam boards.

Installation Process: Spray Foam vs Board Foam

Spray foam installation involves applying a liquid foam that rapidly expands to fill cavities and hard-to-reach areas, creating an airtight seal in a single step. Board foam installation requires cutting rigid foam panels to size and securing them with adhesive or fasteners, often followed by sealing joints with tape or sealant to prevent air leaks. Spray foam generally offers faster application with better coverage, while board foam demands more manual fitting and additional sealing effort.

Cost Analysis: Spray Foam vs Board Foam

Spray foam insulation typically incurs higher upfront costs, ranging from $1.00 to $3.00 per board foot, compared to board foam panels, which cost between $0.25 and $1.00 per square foot. Despite the initial expense, spray foam offers superior air sealing and higher R-values, often between R-6 and R-7 per inch, potentially reducing long-term energy bills more effectively than board foam's R-values of R-3.6 to R-8. Board foam provides a budget-friendly option with easier installation but may require additional sealing materials, increasing overall expenditure.

Moisture Resistance and Air Sealing

Spray foam insulation offers superior moisture resistance due to its ability to expand and create a seamless air barrier, effectively reducing air leakage and preventing water infiltration. In contrast, board foam insulation may allow gaps at seams and edges, increasing the risk of moisture accumulation and compromised air sealing. Choosing spray foam enhances overall energy efficiency and protects building structures from mold and water damage through its excellent sealing properties.

Environmental Impact and Sustainability

Spray foam insulation offers superior air sealing, reducing energy consumption and greenhouse gas emissions by enhancing building efficiency. Board foam panels, typically made from rigid polystyrene or polyisocyanurate, have varying environmental impacts depending on the manufacturing process and recycled content. Selecting materials with low global warming potential (GWP) blowing agents and recyclable attributes can significantly improve sustainability in both spray and board foam options.

Durability and Longevity

Spray foam insulation offers superior durability due to its seamless application, which prevents moisture infiltration and air leaks that can degrade other materials over time. Board foam insulation, while dense and effective, may be more susceptible to warping or moisture damage at seams, reducing its overall longevity. Over extended periods, spray foam maintains structural integrity and insulation performance better in diverse environmental conditions.

Best Applications for Spray Foam and Board Foam

Spray foam insulation excels in sealing irregular cavities and hard-to-reach areas, providing superior air tightness and high R-values per inch, making it ideal for attic roofs, wall cavities, and rim joists. Board foam, such as polyisocyanurate or extruded polystyrene, offers consistent thickness and is best suited for flat roof assemblies, continuous exterior insulation, and insulating basement walls where moisture resistance and dimensional stability are critical. Choosing spray foam enhances energy efficiency in complex structures, while board foam is optimal for uniform insulation layers and vapor control in commercial and residential building envelopes.

Choosing the Right Foam: Factors to Consider

Spray foam offers superior air sealing and higher R-values per inch, making it ideal for irregular surfaces and tight spaces, while board foam provides consistent thickness and is easier to install on flat surfaces. Key factors to consider include the specific application's thermal resistance needs, moisture control requirements, and budget constraints. Evaluating installation complexity and long-term durability helps determine which foam type aligns best with your insulation goals.

Spray foam vs Board foam Infographic

materialdif.com

materialdif.com