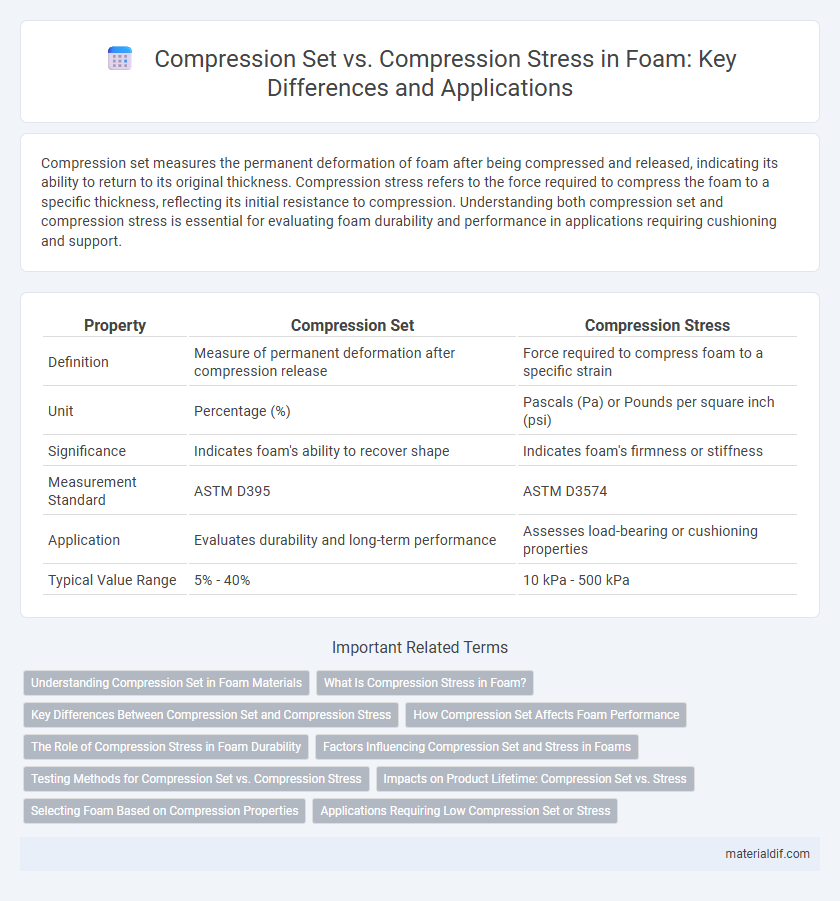

Compression set measures the permanent deformation of foam after being compressed and released, indicating its ability to return to its original thickness. Compression stress refers to the force required to compress the foam to a specific thickness, reflecting its initial resistance to compression. Understanding both compression set and compression stress is essential for evaluating foam durability and performance in applications requiring cushioning and support.

Table of Comparison

| Property | Compression Set | Compression Stress |

|---|---|---|

| Definition | Measure of permanent deformation after compression release | Force required to compress foam to a specific strain |

| Unit | Percentage (%) | Pascals (Pa) or Pounds per square inch (psi) |

| Significance | Indicates foam's ability to recover shape | Indicates foam's firmness or stiffness |

| Measurement Standard | ASTM D395 | ASTM D3574 |

| Application | Evaluates durability and long-term performance | Assesses load-bearing or cushioning properties |

| Typical Value Range | 5% - 40% | 10 kPa - 500 kPa |

Understanding Compression Set in Foam Materials

Compression set refers to the permanent deformation a foam material retains after being subjected to a compressive force and then allowed to recover. It is a critical parameter for evaluating foam's long-term durability and resilience in applications like cushioning and sealing. Unlike compression stress, which measures the resistance of foam under load, compression set directly indicates the foam's ability to regain its original thickness after repeated compressions.

What Is Compression Stress in Foam?

Compression stress in foam refers to the internal force per unit area that resists deformation when the foam is compressed. It measures the foam's ability to withstand applied loads without permanently deforming, reflecting its structural integrity under pressure. This property is crucial in applications requiring cushioning, support, and impact absorption, where maintaining shape under stress is essential.

Key Differences Between Compression Set and Compression Stress

Compression set measures the permanent deformation a foam undergoes after prolonged compression, indicating its ability to return to original thickness, while compression stress quantifies the foam's resistance to compression under a specific load. Key differences include compression set reflecting long-term material durability and recovery capacity, whereas compression stress provides instant mechanical response and cushioning performance. Understanding these parameters is essential for applications requiring precise foam resilience and load-bearing characteristics.

How Compression Set Affects Foam Performance

Compression set measures the permanent deformation of foam after prolonged compression, directly impacting its ability to recover its original thickness and cushioning properties. Higher compression set values indicate reduced elastic recovery, leading to diminished comfort, support, and durability in foam products. Compression stress reflects the foam's resistance to deformation under load, but compression set is critical for assessing long-term performance and resilience in applications like cushions, seals, and packaging.

The Role of Compression Stress in Foam Durability

Compression stress directly impacts foam durability by influencing its ability to resist permanent deformation under load. Higher compression stress levels correlate with improved structural integrity and longer service life, as the foam can better maintain its shape and cushioning properties. Understanding compression stress is essential for designing foam materials that endure repeated compression without significant loss of functionality.

Factors Influencing Compression Set and Stress in Foams

Compression set and compression stress in foams are influenced by factors such as foam density, cellular structure, and material composition. Temperature and duration of applied load also significantly affect the foam's ability to recover after deformation and its resistance to compression. Higher density foams with closed-cell structures typically exhibit lower compression set and higher compression stress, indicating better durability and resilience.

Testing Methods for Compression Set vs. Compression Stress

Compression set testing measures a foam's ability to return to its original thickness after prolonged compressive stress following ASTM D395 or ISO 1856 standards. Compression stress testing evaluates foam's load-bearing capacity and deformation under a specified strain, typically following ASTM D3574 guidelines. These distinct methods provide critical data for assessing foam durability and performance in applications requiring resilience or structural support.

Impacts on Product Lifetime: Compression Set vs. Stress

Compression set measures the permanent deformation of foam after prolonged compression, directly influencing product lifetime by indicating material fatigue and loss of cushioning ability. Compression stress reflects the force required to deform the foam, affecting durability under load but not necessarily predicting long-term shape retention. A lower compression set ensures better dimension stability and extended product lifespan, while higher compression stress contributes to initial structural support without guaranteeing longevity.

Selecting Foam Based on Compression Properties

Selecting foam based on compression properties requires understanding the difference between compression set and compression stress. Compression set measures the foam's ability to recover its original thickness after prolonged compressive force, indicating long-term durability and resilience. Compression stress reflects the foam's resistance to deformation under load, critical for applications demanding structural support and cushioning performance.

Applications Requiring Low Compression Set or Stress

Foams used in applications requiring low compression set maintain their original thickness and resilience after repeated loading, ensuring long-term cushioning and sealing performance. Compression stress measures the force needed to compress the foam to a specific thickness, affecting comfort and durability in products like mattresses and automotive seats. Selecting foams with low compression set and appropriate compression stress values prevents permanent deformation and enhances the foam's lifespan in critical sealing and vibration control applications.

Compression set vs Compression stress Infographic

materialdif.com

materialdif.com