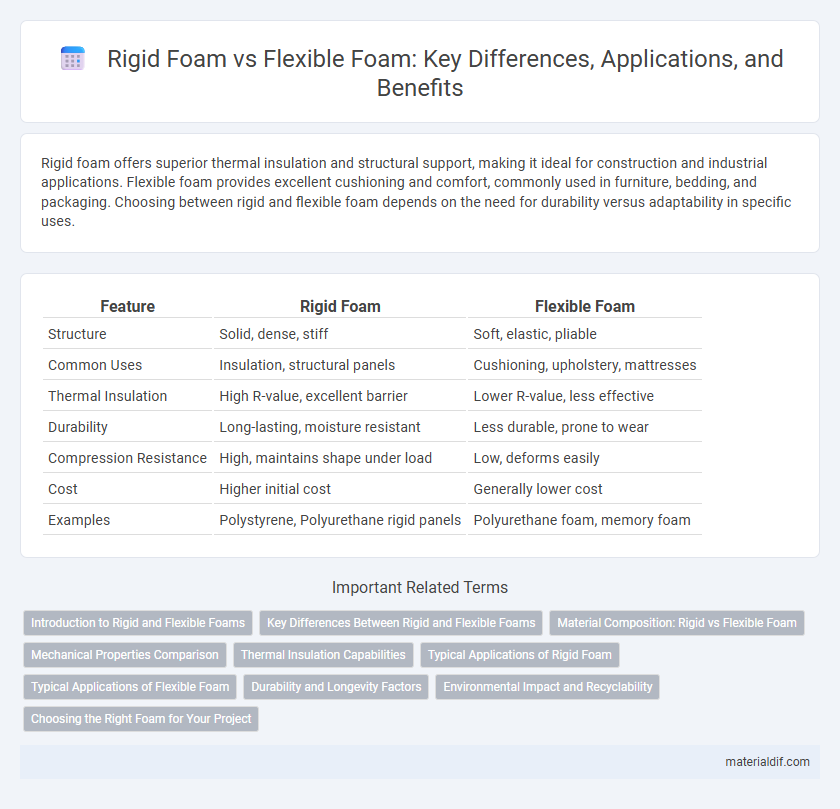

Rigid foam offers superior thermal insulation and structural support, making it ideal for construction and industrial applications. Flexible foam provides excellent cushioning and comfort, commonly used in furniture, bedding, and packaging. Choosing between rigid and flexible foam depends on the need for durability versus adaptability in specific uses.

Table of Comparison

| Feature | Rigid Foam | Flexible Foam |

|---|---|---|

| Structure | Solid, dense, stiff | Soft, elastic, pliable |

| Common Uses | Insulation, structural panels | Cushioning, upholstery, mattresses |

| Thermal Insulation | High R-value, excellent barrier | Lower R-value, less effective |

| Durability | Long-lasting, moisture resistant | Less durable, prone to wear |

| Compression Resistance | High, maintains shape under load | Low, deforms easily |

| Cost | Higher initial cost | Generally lower cost |

| Examples | Polystyrene, Polyurethane rigid panels | Polyurethane foam, memory foam |

Introduction to Rigid and Flexible Foams

Rigid foam exhibits high structural strength and low thermal conductivity, making it ideal for insulation and structural applications. Flexible foam offers superior cushioning, elasticity, and comfort, commonly used in upholstery, mattresses, and packaging. Both types differ primarily in cell structure, density, and mechanical properties, catering to diverse industrial needs.

Key Differences Between Rigid and Flexible Foams

Rigid foam is characterized by its high density and structural strength, making it ideal for insulation and load-bearing applications, whereas flexible foam offers superior cushioning and resilience for comfort-focused uses such as upholstery and mattresses. Thermal insulation values differ significantly, with rigid foam providing better R-values per inch compared to flexible foam. Additionally, rigid foam exhibits low water absorption and greater dimensional stability, while flexible foam is prone to compression and deformation under sustained pressure.

Material Composition: Rigid vs Flexible Foam

Rigid foam is primarily composed of materials like polyurethane, polyisocyanurate, or polystyrene, creating a dense, closed-cell structure that provides high insulation and structural strength. Flexible foam, often made from polyether or polyester-based polyurethane, features an open-cell structure that allows for greater elasticity and cushioning properties. The molecular composition of rigid foams results in better thermal resistance, while flexible foams prioritize softness and flexibility due to their polymer chain arrangement.

Mechanical Properties Comparison

Rigid foam exhibits higher compressive strength and superior structural integrity, making it ideal for load-bearing applications. In contrast, flexible foam provides enhanced elasticity and impact absorption, excelling in cushioning and insulation uses. The mechanical properties of rigid foam include limited deformation under stress, whereas flexible foam offers significant deformation recovery and resilience.

Thermal Insulation Capabilities

Rigid foam provides superior thermal insulation capabilities due to its higher R-value per inch, making it ideal for walls, roofs, and foundations where maximum energy efficiency is required. Flexible foam, while offering moderate insulation, excels in applications needing cushioning and soundproofing rather than primary thermal resistance. The closed-cell structure of rigid foam minimizes heat transfer effectively compared to the open-cell composition typically found in flexible foam.

Typical Applications of Rigid Foam

Rigid foam is widely used in insulation for building walls, roofs, and foundations due to its high compressive strength and low thermal conductivity. It is also employed in structural panels, refrigeration units, and protective packaging where durability and moisture resistance are essential. Typical applications of rigid foam include thermal insulation in HVAC systems, construction materials, and automotive parts for enhanced energy efficiency.

Typical Applications of Flexible Foam

Flexible foam is widely used in furniture manufacturing, providing cushioning for sofas, chairs, and mattresses due to its superior comfort and resilience. Automotive industries rely on flexible foam for seat padding, interior panels, and sound insulation, enhancing passenger comfort and noise reduction. Additionally, flexible foam is essential in packaging, protecting delicate electronics and consumer goods through impact absorption and lightweight properties.

Durability and Longevity Factors

Rigid foam offers superior durability and longevity due to its high density and resistance to compression, making it ideal for structural applications and insulation that requires long-term performance. Flexible foam, while providing excellent comfort and cushioning, tends to degrade faster under repeated stress and environmental exposure, resulting in a shorter lifespan. Material composition and cellular structure are key factors influencing the resilience and durability differences between rigid and flexible foams.

Environmental Impact and Recyclability

Rigid foam typically has a higher environmental impact due to its production involving blowing agents with global warming potential and limited recyclability, often ending up in landfills. Flexible foam, while also challenging to recycle, generally uses less energy in manufacturing and often incorporates more recycled content, reducing its overall carbon footprint. Innovations in chemical recycling and improved collection systems are enhancing the recyclability of both foam types, but rigid foam remains more problematic environmentally.

Choosing the Right Foam for Your Project

Rigid foam provides superior insulation and structural support, ideal for walls, roofs, and foundation applications requiring durability and moisture resistance. Flexible foam offers excellent cushioning and shock absorption, making it perfect for upholstery, mattresses, and packaging where comfort and flexibility are priorities. Selecting the right foam depends on project requirements such as load-bearing capacity, thermal insulation needs, and desired comfort level.

Rigid foam vs Flexible foam Infographic

materialdif.com

materialdif.com