Melamine foam offers superior sound absorption and fire resistance compared to polyether foam, making it ideal for acoustic insulation and safety applications. Polyether foam provides better flexibility and durability, often used in cushioning and packaging where comfort and resilience are prioritized. Selecting between melamine and polyether foam depends on the specific needs of thermal insulation, acoustic performance, and mechanical properties.

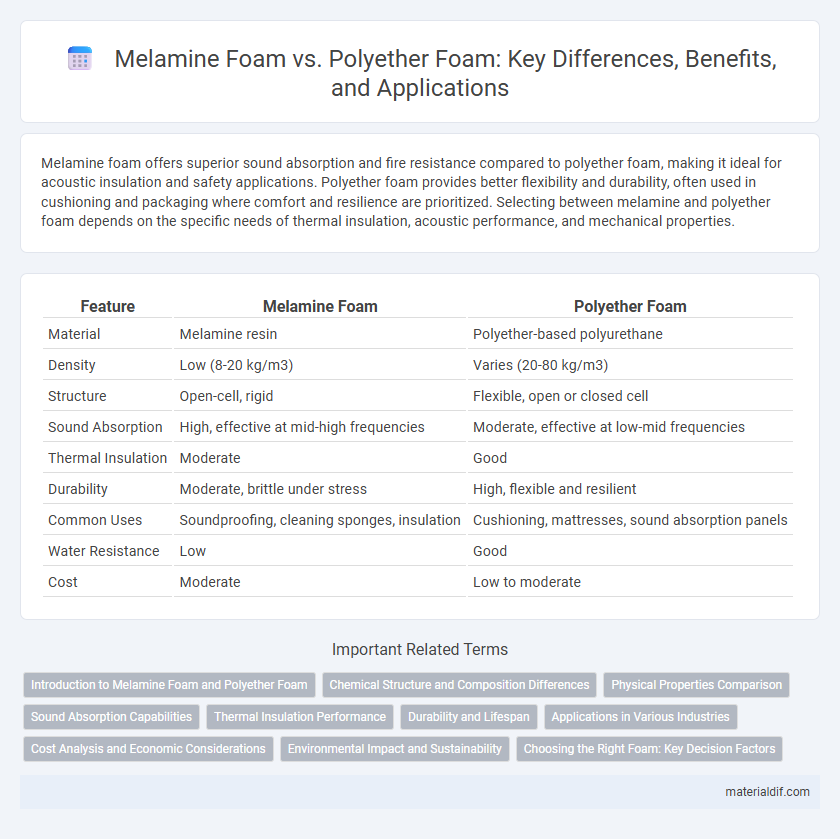

Table of Comparison

| Feature | Melamine Foam | Polyether Foam |

|---|---|---|

| Material | Melamine resin | Polyether-based polyurethane |

| Density | Low (8-20 kg/m3) | Varies (20-80 kg/m3) |

| Structure | Open-cell, rigid | Flexible, open or closed cell |

| Sound Absorption | High, effective at mid-high frequencies | Moderate, effective at low-mid frequencies |

| Thermal Insulation | Moderate | Good |

| Durability | Moderate, brittle under stress | High, flexible and resilient |

| Common Uses | Soundproofing, cleaning sponges, insulation | Cushioning, mattresses, sound absorption panels |

| Water Resistance | Low | Good |

| Cost | Moderate | Low to moderate |

Introduction to Melamine Foam and Polyether Foam

Melamine foam is a lightweight, rigid open-cell foam known for its exceptional sound absorption and thermal insulation properties, commonly used in acoustic panels and cleaning products. Polyether foam, a type of polyurethane foam, offers high resilience, flexibility, and resistance to moisture, making it ideal for cushioning and bedding applications. Both foams differ in chemical structure and performance characteristics, influencing their suitability for various industrial and consumer uses.

Chemical Structure and Composition Differences

Melamine foam consists of a three-dimensional, open-celled network formed by melamine-formaldehyde resin, characterized by its thermosetting polymer structure that provides high heat resistance and rigidity. Polyether foam is composed of polyurethane chains with flexible polyether segments, creating a thermoplastic elastomer that offers softness and resilience due to its urethane linkages and ether groups. The chemical structure of melamine foam leads to greater thermal stability and chemical resistance, while polyether foam's composition results in enhanced elasticity and water absorption properties.

Physical Properties Comparison

Melamine foam exhibits a rigid, open-cell structure with excellent thermal insulation and fire resistance, making it lightweight and highly durable under heat exposure. Polyether foam, characterized by its soft, closed-cell composition, offers superior cushioning, flexibility, and impact absorption, but lower thermal stability compared to melamine. Moisture resistance in polyether foam surpasses that of melamine foam, which tends to absorb water due to its porous nature.

Sound Absorption Capabilities

Melamine foam offers superior sound absorption properties compared to polyether foam, due to its open-cell structure that effectively traps and dissipates sound waves across a wide frequency range. Polyether foam typically exhibits lower sound absorption coefficients, making it less effective in noise reduction applications. Melamine foam's lightweight and high porosity make it an ideal choice for acoustic insulation in environments requiring enhanced noise control.

Thermal Insulation Performance

Melamine foam offers superior thermal insulation due to its open-cell structure and low thermal conductivity, making it highly effective in reducing heat transfer in various applications. Polyether foam, while also providing insulation, generally has higher thermal conductivity and less stability at elevated temperatures compared to melamine foam. The choice of foam depends on specific thermal insulation requirements, with melamine foam preferred for high-performance, fire-resistant insulation solutions.

Durability and Lifespan

Melamine foam offers superior durability and a longer lifespan compared to polyether foam due to its rigid, open-cell structure that resists wear and deformation over time. Polyether foam, while flexible and resilient, tends to degrade faster under prolonged mechanical stress and exposure to environmental factors. For applications requiring sustained performance and longevity, melamine foam is the more durable and reliable choice.

Applications in Various Industries

Melamine foam excels in fire-resistant applications and soundproofing in automotive, construction, and HVAC industries due to its lightweight and open-cell structure. Polyether foam is widely used in cushioning, packaging, and medical devices, offering superior flexibility and water resistance suited for bedding, furniture, and prosthetics. Both foams serve critical roles across sectors, with melamine favored for thermal insulation and polyether preferred for comfort and durability.

Cost Analysis and Economic Considerations

Melamine foam generally costs more per cubic meter than polyether foam due to its specialized manufacturing process and superior sound absorption properties. Polyether foam offers a more economical option for applications where budget constraints are critical, albeit with lower durability and acoustic performance. Evaluating total lifecycle costs including material longevity and maintenance can reveal that melamine foam provides better value in high-performance environments despite the higher upfront investment.

Environmental Impact and Sustainability

Melamine foam offers superior sustainability due to its low density and ability to be produced from formaldehyde-based resins with reduced environmental hazards compared to polyether foam, which relies on petroleum-derived polyols contributing to higher carbon emissions. Melamine foam is non-toxic, fully recyclable, and demonstrates excellent biodegradability, whereas polyether foam typically persists longer in landfills and resists natural degradation. The environmental impact of melamine foam is minimized through energy-efficient production methods and its potential for reuse in insulation and filtration, contrasting with the more resource-intensive manufacture and disposal challenges associated with polyether foam.

Choosing the Right Foam: Key Decision Factors

Melamine foam offers superior sound absorption and fire resistance, making it ideal for acoustic insulation and safety applications, whereas polyether foam provides excellent cushioning and moisture resistance suited for upholstery and bedding. Key decision factors include application environment, durability needs, and desired physical properties such as density and compressibility. Cost efficiency and ease of fabrication also influence the choice between melamine and polyether foams.

Melamine foam vs Polyether foam Infographic

materialdif.com

materialdif.com