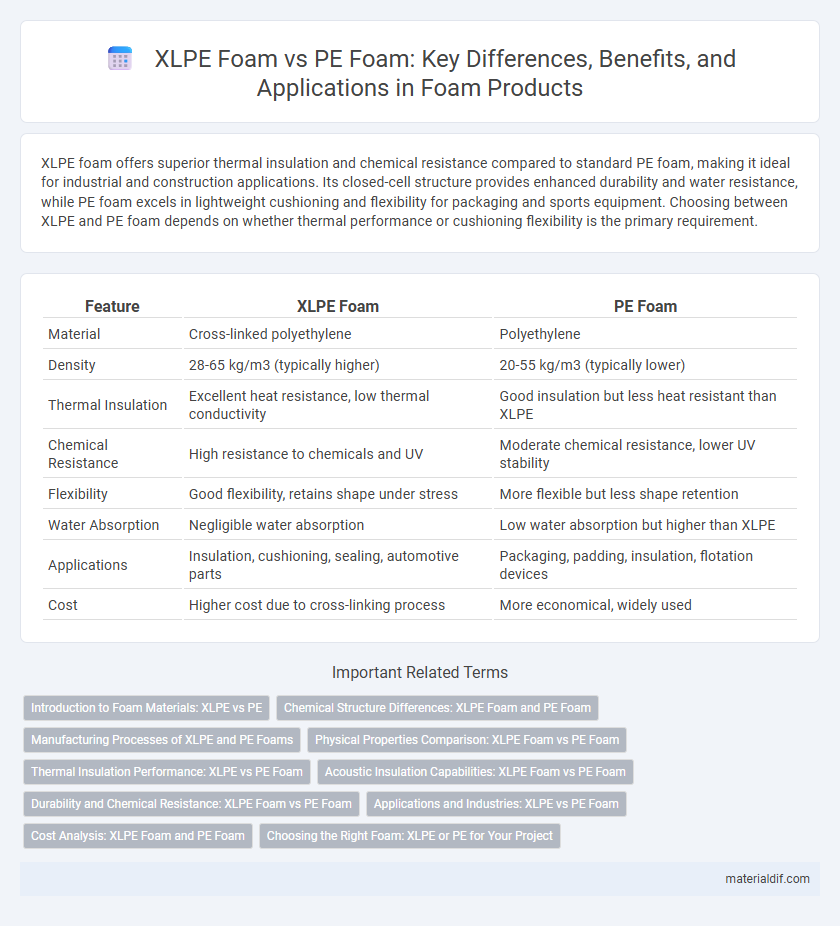

XLPE foam offers superior thermal insulation and chemical resistance compared to standard PE foam, making it ideal for industrial and construction applications. Its closed-cell structure provides enhanced durability and water resistance, while PE foam excels in lightweight cushioning and flexibility for packaging and sports equipment. Choosing between XLPE and PE foam depends on whether thermal performance or cushioning flexibility is the primary requirement.

Table of Comparison

| Feature | XLPE Foam | PE Foam |

|---|---|---|

| Material | Cross-linked polyethylene | Polyethylene |

| Density | 28-65 kg/m3 (typically higher) | 20-55 kg/m3 (typically lower) |

| Thermal Insulation | Excellent heat resistance, low thermal conductivity | Good insulation but less heat resistant than XLPE |

| Chemical Resistance | High resistance to chemicals and UV | Moderate chemical resistance, lower UV stability |

| Flexibility | Good flexibility, retains shape under stress | More flexible but less shape retention |

| Water Absorption | Negligible water absorption | Low water absorption but higher than XLPE |

| Applications | Insulation, cushioning, sealing, automotive parts | Packaging, padding, insulation, flotation devices |

| Cost | Higher cost due to cross-linking process | More economical, widely used |

Introduction to Foam Materials: XLPE vs PE

XLPE foam, or cross-linked polyethylene foam, offers superior thermal insulation, chemical resistance, and durability compared to standard PE foam, which is polyethylene-based but lacks cross-linking. The cross-linking process in XLPE foam enhances its mechanical strength and resilience, making it ideal for applications in automotive, construction, and sports equipment sectors. PE foam remains a cost-effective option for general padding and packaging, but XLPE foam's closed-cell structure provides enhanced performance in harsh environments.

Chemical Structure Differences: XLPE Foam and PE Foam

XLPE foam, or cross-linked polyethylene foam, features a three-dimensional cross-linked molecular network that significantly enhances its thermal stability, chemical resistance, and mechanical strength compared to standard PE foam. PE foam, made from linear polyethylene chains, lacks the cross-linked structure, resulting in lower resistance to heat, compression, and chemical degradation. The chemical cross-linking process in XLPE foam creates covalent bonds between polymer chains, modifying its physical properties and making it ideal for applications requiring durability and insulation.

Manufacturing Processes of XLPE and PE Foams

XLPE foam is produced through a cross-linking process involving high temperature and chemical agents that transform polyethylene chains into a three-dimensional network, enhancing thermal resistance and mechanical strength. In contrast, PE foam manufacturing typically involves physical expansion methods such as gas injection or chemical blowing agents without cross-linking, resulting in a softer and more flexible structure. The cross-linking step in XLPE foam production leads to superior durability and resistance to environmental stress compared to conventional PE foam.

Physical Properties Comparison: XLPE Foam vs PE Foam

XLPE foam exhibits superior tensile strength and higher compression resistance compared to PE foam, making it ideal for applications requiring enhanced durability. XLPE foam also demonstrates better thermal stability and greater resistance to chemicals, while PE foam offers more flexibility and lower density, contributing to improved cushioning properties. Both foams provide excellent insulation, but XLPE foam's closed-cell structure ensures less water absorption and longer service life under harsh conditions.

Thermal Insulation Performance: XLPE vs PE Foam

XLPE foam exhibits superior thermal insulation performance compared to PE foam due to its closed-cell structure, which effectively reduces heat transfer and enhances energy efficiency. The cross-linked polyethylene (XLPE) foam maintains stable thermal resistance even under varying temperature conditions, making it ideal for HVAC and piping insulation. In contrast, standard PE foam has higher thermal conductivity and less dimensional stability, resulting in lower insulation effectiveness.

Acoustic Insulation Capabilities: XLPE Foam vs PE Foam

XLPE foam exhibits superior acoustic insulation capabilities compared to PE foam due to its cross-linked molecular structure, which enhances sound absorption and reduces noise transmission effectively. The dense, closed-cell structure of XLPE foam minimizes sound wave penetration, making it ideal for applications requiring high noise reduction. In contrast, PE foam, with its open-cell design, offers moderate sound insulation but lacks the robustness of XLPE in blocking airborne and impact noises.

Durability and Chemical Resistance: XLPE Foam vs PE Foam

XLPE foam exhibits superior durability and chemical resistance compared to PE foam, making it ideal for applications exposed to harsh environments and aggressive chemicals. Its cross-linked structure provides enhanced resistance to abrasion, heat, and solvents, while PE foam tends to degrade faster under similar conditions. This makes XLPE foam the preferred choice for industrial insulation, automotive components, and chemical packaging where long-lasting performance is critical.

Applications and Industries: XLPE vs PE Foam

XLPE foam is widely used in automotive, construction, and electrical insulation industries due to its superior thermal resistance, dimensional stability, and chemical resistance. PE foam, favored for its lightweight, cushioning, and shock absorption properties, is commonly applied in packaging, sports equipment, and marine industries. Both foams serve critical roles in manufacturing, with XLPE foam excelling in demanding structural environments and PE foam preferred for flexible, impact-resistant applications.

Cost Analysis: XLPE Foam and PE Foam

XLPE foam typically incurs higher production costs due to cross-linking processes increasing durability and thermal insulation properties compared to standard PE foam. PE foam offers a cost-effective alternative with lower raw material and manufacturing expenses, making it suitable for budget-sensitive applications. When balancing performance requirements and budget constraints, selecting PE foam may reduce initial costs, while XLPE foam's extended lifespan can provide better long-term value.

Choosing the Right Foam: XLPE or PE for Your Project

XLPE foam offers superior thermal insulation and chemical resistance due to its cross-linked polyethylene structure, making it ideal for high-performance applications in automotive and construction industries. PE foam provides excellent cushioning, flexibility, and cost-effectiveness, suitable for packaging, sports equipment, and general-purpose use. Selecting between XLPE and PE foam depends on project requirements such as durability, environmental exposure, and mechanical stresses to ensure optimal performance and longevity.

XLPE foam vs PE foam Infographic

materialdif.com

materialdif.com