Spray foam insulation offers superior air sealing by expanding to fill gaps and cracks, creating a seamless barrier that enhances energy efficiency in pets' living environments. Board foam insulation provides consistent thermal resistance with rigid panels ideal for structural applications, but may require additional sealing to prevent air leaks. Choosing between spray foam and board foam insulation depends on the desired airtightness and installation flexibility for optimal comfort and protection in pet spaces.

Table of Comparison

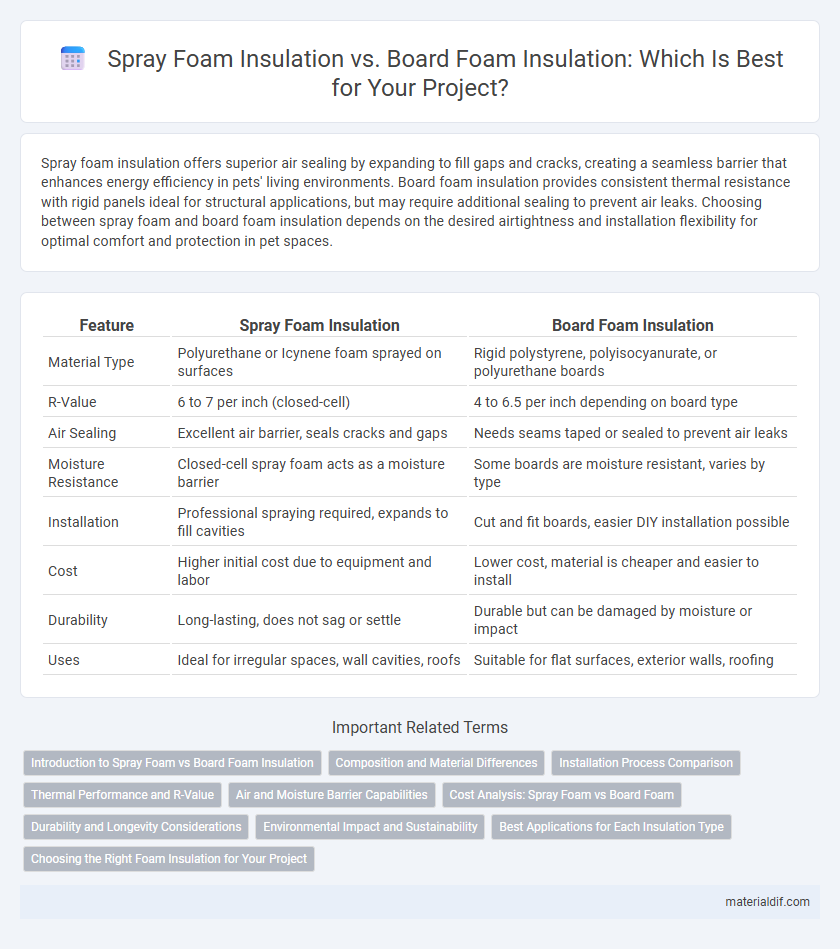

| Feature | Spray Foam Insulation | Board Foam Insulation |

|---|---|---|

| Material Type | Polyurethane or Icynene foam sprayed on surfaces | Rigid polystyrene, polyisocyanurate, or polyurethane boards |

| R-Value | 6 to 7 per inch (closed-cell) | 4 to 6.5 per inch depending on board type |

| Air Sealing | Excellent air barrier, seals cracks and gaps | Needs seams taped or sealed to prevent air leaks |

| Moisture Resistance | Closed-cell spray foam acts as a moisture barrier | Some boards are moisture resistant, varies by type |

| Installation | Professional spraying required, expands to fill cavities | Cut and fit boards, easier DIY installation possible |

| Cost | Higher initial cost due to equipment and labor | Lower cost, material is cheaper and easier to install |

| Durability | Long-lasting, does not sag or settle | Durable but can be damaged by moisture or impact |

| Uses | Ideal for irregular spaces, wall cavities, roofs | Suitable for flat surfaces, exterior walls, roofing |

Introduction to Spray Foam vs Board Foam Insulation

Spray foam insulation offers superior air sealing and higher R-values per inch compared to board foam insulation, making it ideal for irregular surfaces and gaps. Board foam insulation typically comes in rigid panels that provide consistent thickness and is easier to install in larger, flat areas. Both types improve energy efficiency but differ in application methods, thermal performance, and moisture resistance.

Composition and Material Differences

Spray foam insulation is composed of polyurethane or polyisocyanurate that expands upon application, creating an airtight seal that adapts to irregular surfaces. Board foam insulation, typically made from extruded polystyrene (XPS), expanded polystyrene (EPS), or polyisocyanurate, comes in rigid panels that provide structural support and consistent R-values. The differing chemical compositions impact thermal resistance, moisture resistance, and installation methods, with spray foam offering superior air sealing and board foam delivering ease of handling and uniform thickness.

Installation Process Comparison

Spray foam insulation requires professional application using specialized equipment, ensuring seamless sealing and expansion into gaps for enhanced energy efficiency. Board foam insulation involves cutting rigid panels to fit and securing them with adhesives or mechanical fasteners, offering a more straightforward DIY installation. Spray foam typically demands more preparation and curing time, whereas board foam installation is quicker but may require meticulous measurement for optimal fit.

Thermal Performance and R-Value

Spray foam insulation offers superior thermal performance with R-values typically ranging from 6 to 7 per inch, providing excellent air sealing capabilities that reduce energy loss. Board foam insulation, such as polyisocyanurate or extruded polystyrene, provides R-values between 3.6 and 6.5 per inch but often requires additional air sealing measures to achieve comparable performance. The continuous, gap-free coverage of spray foam enhances overall energy efficiency, making it more effective in minimizing thermal bridging compared to rigid board foam.

Air and Moisture Barrier Capabilities

Spray foam insulation excels in providing a seamless air and moisture barrier by expanding to fill gaps and cracks, reducing infiltration and preventing humidity buildup. Board foam insulation, while effective as a thermal barrier, typically requires additional sealing to achieve comparable air and moisture resistance. Proper installation of spray foam significantly enhances energy efficiency and indoor air quality by minimizing air leaks and controlling moisture penetration.

Cost Analysis: Spray Foam vs Board Foam

Spray foam insulation typically costs between $1.50 to $3.00 per square foot, offering superior air sealing and higher R-values per inch compared to board foam, which ranges from $0.25 to $0.50 per square foot but often requires additional materials and labor for installation. Despite a higher upfront expense, spray foam provides long-term energy savings due to its superior thermal performance and reduced air leakage. Board foam insulation remains a cost-effective choice for budget-conscious projects, especially in areas with straightforward installation needs and where thermal bridging control is less critical.

Durability and Longevity Considerations

Spray foam insulation offers superior durability due to its seamless application and strong adhesion, which minimizes gaps and air leaks, extending the life of the insulation. Board foam insulation, while effective, can be prone to damage at seams and edges, potentially reducing its longevity in high-traffic or moisture-prone areas. Both types benefit from proper installation, but spray foam generally provides longer-lasting performance in maintaining energy efficiency and structural integrity.

Environmental Impact and Sustainability

Spray foam insulation typically uses chemicals that can release volatile organic compounds (VOCs) and often relies on blowing agents with high global warming potential, raising environmental concerns. Board foam insulation, especially those made from recycled materials or natural fibers, tends to have a lower environmental footprint and offers better sustainability through recyclability and reduced emissions during production. Choosing board foam insulation can contribute to greener building practices by minimizing toxic emissions and improving material lifecycle impact.

Best Applications for Each Insulation Type

Spray foam insulation excels in sealing irregular or hard-to-reach areas, making it ideal for attics, crawl spaces, and around HVAC ducts where airtightness is crucial. Board foam insulation, such as polyisocyanurate or extruded polystyrene panels, is best suited for flat surfaces like basement walls, exterior sheathing, and under roofing due to its rigid structure and high compressive strength. Selecting the appropriate insulation type depends on factors like surface geometry, moisture exposure, and desired thermal performance.

Choosing the Right Foam Insulation for Your Project

Spray foam insulation offers superior air sealing and higher R-values per inch, making it ideal for irregularly shaped spaces and tight areas requiring maximum energy efficiency. Board foam insulation provides consistent thickness, easy handling, and is effective for large, flat surfaces like walls and roofs where uniformity is essential. Selecting the right foam insulation depends on project-specific factors such as climate, budget, installation complexity, and desired thermal performance.

Spray foam insulation vs Board foam insulation Infographic

materialdif.com

materialdif.com