Molded foam offers precise shaping and uniform density by being formed in custom molds, ensuring consistent performance and durability for specific applications. Cut foam is created by slicing large foam blocks into desired shapes, offering greater flexibility and cost-effectiveness for varied or smaller production runs. Choosing between molded and cut foam depends on the project's requirements for precision, volume, and budget constraints.

Table of Comparison

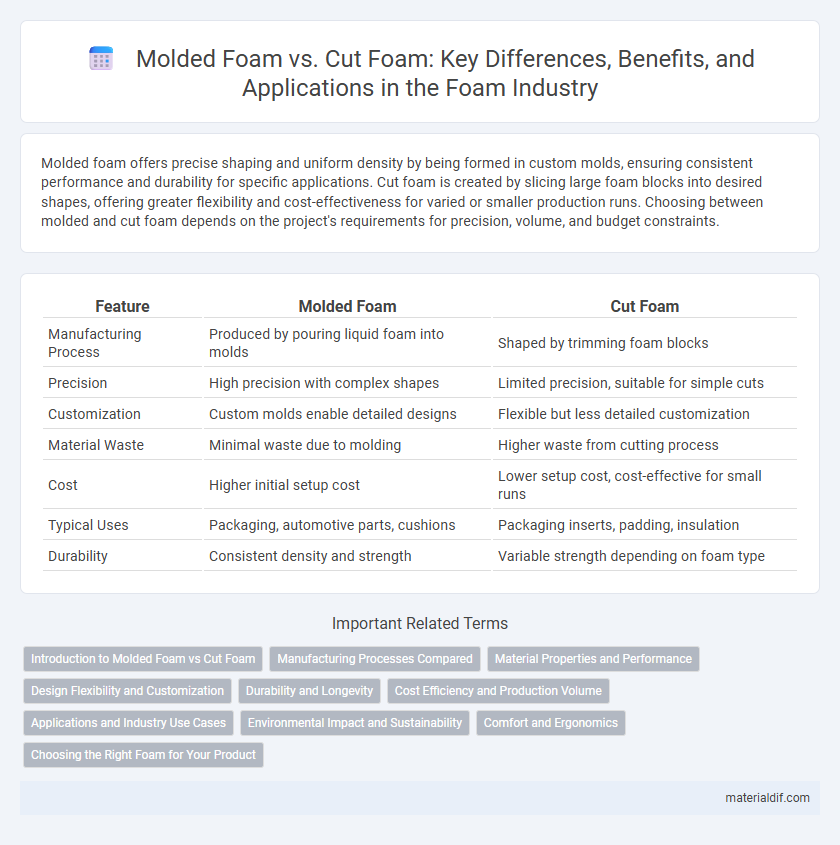

| Feature | Molded Foam | Cut Foam |

|---|---|---|

| Manufacturing Process | Produced by pouring liquid foam into molds | Shaped by trimming foam blocks |

| Precision | High precision with complex shapes | Limited precision, suitable for simple cuts |

| Customization | Custom molds enable detailed designs | Flexible but less detailed customization |

| Material Waste | Minimal waste due to molding | Higher waste from cutting process |

| Cost | Higher initial setup cost | Lower setup cost, cost-effective for small runs |

| Typical Uses | Packaging, automotive parts, cushions | Packaging inserts, padding, insulation |

| Durability | Consistent density and strength | Variable strength depending on foam type |

Introduction to Molded Foam vs Cut Foam

Molded foam is produced by injecting foam material into a mold to create precisely shaped, seamless products with consistent density, ideal for protective packaging and custom cushioning. Cut foam refers to foam sheets or blocks that are sliced into specific shapes and sizes, offering flexibility and cost-effectiveness for applications such as upholstery and DIY projects. Both types vary in manufacturing processes and are chosen based on durability, customization needs, and intended use.

Manufacturing Processes Compared

Molded foam is produced by injecting liquid foam into a mold where it expands and solidifies, allowing for complex shapes and consistent density, while cut foam is created by slicing large foam blocks into specific sizes and shapes using hot wire or CNC machines. The molded foam process enables faster production of detailed and durable pieces, ideal for applications requiring intricate contours and uniformity, whereas cut foam offers flexibility in dimensions and lower initial tooling costs. Manufacturing molded foam involves chemical reactions and precise mold design, contrasting with the mechanical nature and minimal material waste characteristic of cut foam fabrication.

Material Properties and Performance

Molded foam exhibits a consistent density and structural integrity, providing superior impact absorption and durability compared to cut foam, which often has irregular density and edge finish due to the slicing process. The closed-cell structure of molded foam enhances resistance to moisture and compression set, making it ideal for high-performance cushioning and insulation applications. Cut foam, while more versatile in shape customization, generally offers lower resilience and can degrade faster under repeated stress and environmental exposure.

Design Flexibility and Customization

Molded foam offers superior design flexibility by allowing complex shapes and intricate details to be created in a single piece, enabling high customization for specific needs. Cut foam is limited to simpler geometric shapes and straight cuts, restricting design variations but offering quicker production for standard forms. Customization in molded foam caters to precise applications like automotive or protective packaging, while cut foam suits general-purpose cushioning and insulation.

Durability and Longevity

Molded foam exhibits superior durability and longevity compared to cut foam due to its seamless construction, which reduces weak points prone to wear and tear. The high-density composition of molded foam maintains its shape and resilience over time, making it ideal for heavy-use applications. Conversely, cut foam, sliced from larger blocks, tends to deteriorate faster under stress due to exposed seams and uneven density distribution.

Cost Efficiency and Production Volume

Molded foam offers superior cost efficiency for high production volumes due to its automated manufacturing process and reduced material waste. Cut foam is more economical for low to medium production runs, allowing flexible customization without the expense of molds. Selecting between molded and cut foam hinges on balancing initial tooling costs against long-term production scale.

Applications and Industry Use Cases

Molded foam provides precise shapes and structural integrity ideal for automotive seating, packaging delicate electronics, and custom medical supports, enhancing durability and comfort. Cut foam offers versatility and cost-effectiveness, widely used in furniture upholstery, soundproofing in architectural projects, and protective gear manufacturing due to its adaptability to various thicknesses and densities. Both types serve distinct roles across industries, with molded foam favored for complex designs and cut foam preferred for straightforward, customizable applications.

Environmental Impact and Sustainability

Molded foam generates less waste during production as it is formed in precise shapes, minimizing material offcuts compared to cut foam, which involves trimming larger blocks and results in significant scrap. The energy consumption of molded foam manufacturing is generally lower due to its efficient process, whereas cut foam requires additional machinery and labor for shaping. Furthermore, molded foam often utilizes recyclable or bio-based materials, enhancing sustainability, while cut foam frequently relies on traditional petrochemical-based foams with limited eco-friendly alternatives.

Comfort and Ergonomics

Molded foam offers superior comfort and ergonomics by conforming precisely to body contours, providing consistent support and pressure distribution. Cut foam, often made from pre-formed sheets, may lack the tailored fit and resilience of molded foam, potentially leading to uneven support and reduced comfort over time. Choosing molded foam enhances ergonomic benefits by promoting proper posture and reducing pressure points in seating or bedding applications.

Choosing the Right Foam for Your Product

Molded foam offers precise shapes and enhanced durability, ideal for products requiring complex designs and consistent cushioning, while cut foam provides flexibility and cost-effectiveness suited for simple or custom-sized applications. Understanding the specific cushioning, aesthetic, and production needs of your product ensures the selection of the right foam type. Prioritize factors like density, resilience, and intended use to achieve optimal performance and customer satisfaction.

Molded foam vs Cut foam Infographic

materialdif.com

materialdif.com