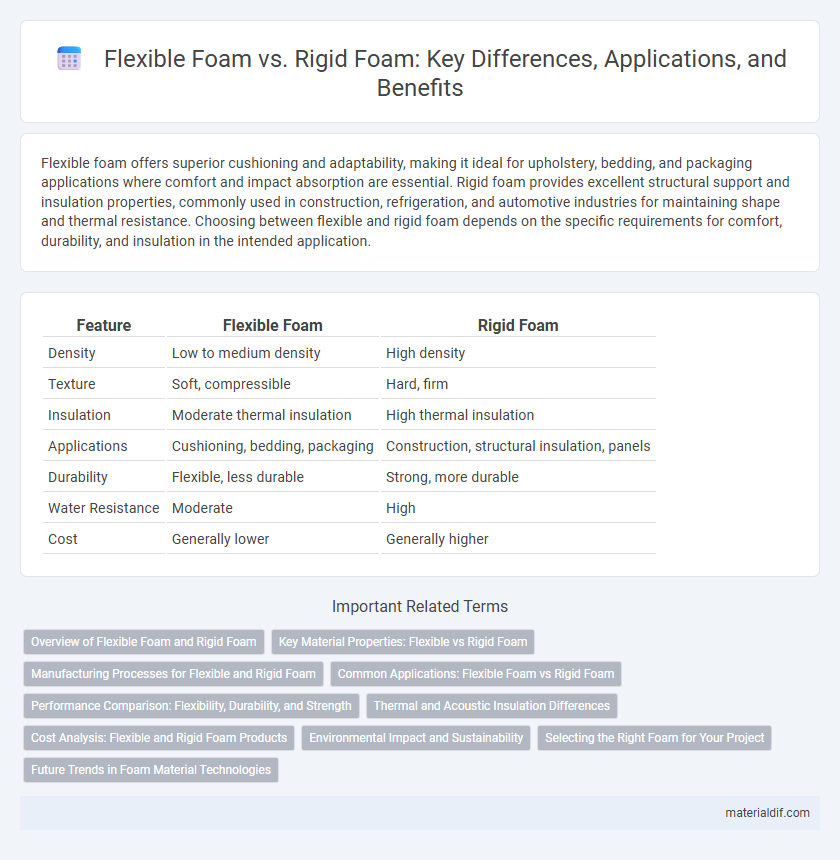

Flexible foam offers superior cushioning and adaptability, making it ideal for upholstery, bedding, and packaging applications where comfort and impact absorption are essential. Rigid foam provides excellent structural support and insulation properties, commonly used in construction, refrigeration, and automotive industries for maintaining shape and thermal resistance. Choosing between flexible and rigid foam depends on the specific requirements for comfort, durability, and insulation in the intended application.

Table of Comparison

| Feature | Flexible Foam | Rigid Foam |

|---|---|---|

| Density | Low to medium density | High density |

| Texture | Soft, compressible | Hard, firm |

| Insulation | Moderate thermal insulation | High thermal insulation |

| Applications | Cushioning, bedding, packaging | Construction, structural insulation, panels |

| Durability | Flexible, less durable | Strong, more durable |

| Water Resistance | Moderate | High |

| Cost | Generally lower | Generally higher |

Overview of Flexible Foam and Rigid Foam

Flexible foam is a lightweight, resilient material characterized by its open-cell structure, commonly used in cushioning, mattresses, and insulation due to its ability to compress and recover. Rigid foam features a closed-cell structure, providing superior structural support, thermal insulation, and resistance to moisture, making it ideal for construction and industrial applications. Both types differ significantly in density, durability, and applications, catering to distinct performance requirements across various industries.

Key Material Properties: Flexible vs Rigid Foam

Flexible foam exhibits high elasticity and compressibility, making it ideal for cushioning, insulation, and sound absorption applications due to its open-cell structure. Rigid foam features a dense, closed-cell architecture that provides superior thermal insulation, structural support, and moisture resistance in building and industrial uses. The key material properties distinguishing flexible foam from rigid foam include flexibility, density, compressive strength, and thermal conductivity.

Manufacturing Processes for Flexible and Rigid Foam

Flexible foam is typically produced using a slab stock or molded foam process where liquid polyol and isocyanate react to form a polymer matrix with open cells, allowing cushioning and elasticity. Rigid foam manufacturing involves a reaction between polyols and isocyanates with blowing agents to create closed-cell structures that provide high thermal resistance and structural support. Both processes require precise control of chemical ratios, temperature, and catalysts to optimize foam density, cell structure, and mechanical properties for specific applications.

Common Applications: Flexible Foam vs Rigid Foam

Flexible foam is commonly used in furniture cushions, mattresses, automotive seating, and packaging due to its softness and ability to absorb shock and vibrations. Rigid foam is widely applied in insulation for buildings, refrigeration units, and structural panels because of its high compressive strength and thermal resistance. Both types serve essential roles in construction, transportation, and consumer products, with flexible foam prioritized for comfort and cushioning, while rigid foam is essential for durability and energy efficiency.

Performance Comparison: Flexibility, Durability, and Strength

Flexible foam offers superior cushioning and shock absorption due to its elasticity, making it ideal for applications requiring comfort and flexibility, such as upholstery and mattresses. Rigid foam excels in structural integrity and compressive strength, providing superior insulation and support in construction and industrial uses. Durability varies with application, as flexible foam resists impact and deformation better, while rigid foam withstands heavy loads and environmental stress without losing shape.

Thermal and Acoustic Insulation Differences

Flexible foam offers superior sound absorption due to its open-cell structure, making it ideal for acoustic insulation in environments requiring noise reduction. Rigid foam, characterized by a closed-cell structure, provides higher thermal resistance (R-value), enhancing energy efficiency in building insulation by minimizing heat transfer. The choice between flexible and rigid foam depends on prioritizing acoustic control with flexible foam or thermal insulation with rigid foam.

Cost Analysis: Flexible and Rigid Foam Products

Flexible foam typically costs more upfront than rigid foam due to its complex manufacturing process and versatile applications, including cushioning and insulation. Rigid foam provides a cost-effective solution for structural insulation, offering higher R-value per inch, which reduces long-term energy expenses despite lower initial material costs. Choosing between flexible and rigid foam depends on balancing upfront material expenses with the intended use and energy savings over time.

Environmental Impact and Sustainability

Flexible foam typically has a lower environmental impact due to its lightweight nature and energy-efficient manufacturing processes, resulting in reduced carbon emissions compared to rigid foam. Rigid foam, often used for insulation, poses sustainability challenges because it commonly relies on blowing agents with high global warming potential and is less biodegradable. Innovations in bio-based flexible foam and recyclable rigid foam materials are key to improving sustainability in foam production.

Selecting the Right Foam for Your Project

Flexible foam offers excellent cushioning and shock absorption, making it ideal for upholstery, mattresses, and packaging applications where comfort and flexibility are critical. Rigid foam provides superior structural support and thermal insulation, suitable for construction, insulation panels, and automotive parts requiring stiffness and durability. Selecting the right foam depends on project requirements such as load-bearing capacity, thermal resistance, and desired flexibility.

Future Trends in Foam Material Technologies

Flexible foam and rigid foam are poised to benefit from advancements in bio-based polymers and enhanced recycling technologies that address environmental sustainability. Innovations in nanomaterials and smart foam systems are expected to improve durability, thermal insulation, and responsiveness to external stimuli. Industry trends focus on reducing carbon footprints while maintaining or enhancing mechanical properties for applications in automotive, construction, and consumer goods.

Flexible Foam vs Rigid Foam Infographic

materialdif.com

materialdif.com