Spray foam offers superior air sealing and insulation by expanding on contact, making it ideal for irregular or hard-to-reach spaces. Injection foam is injected into cavities where access is limited, providing efficient insulation without major demolition. Both types improve energy efficiency, but spray foam typically provides a more continuous barrier against air and moisture.

Table of Comparison

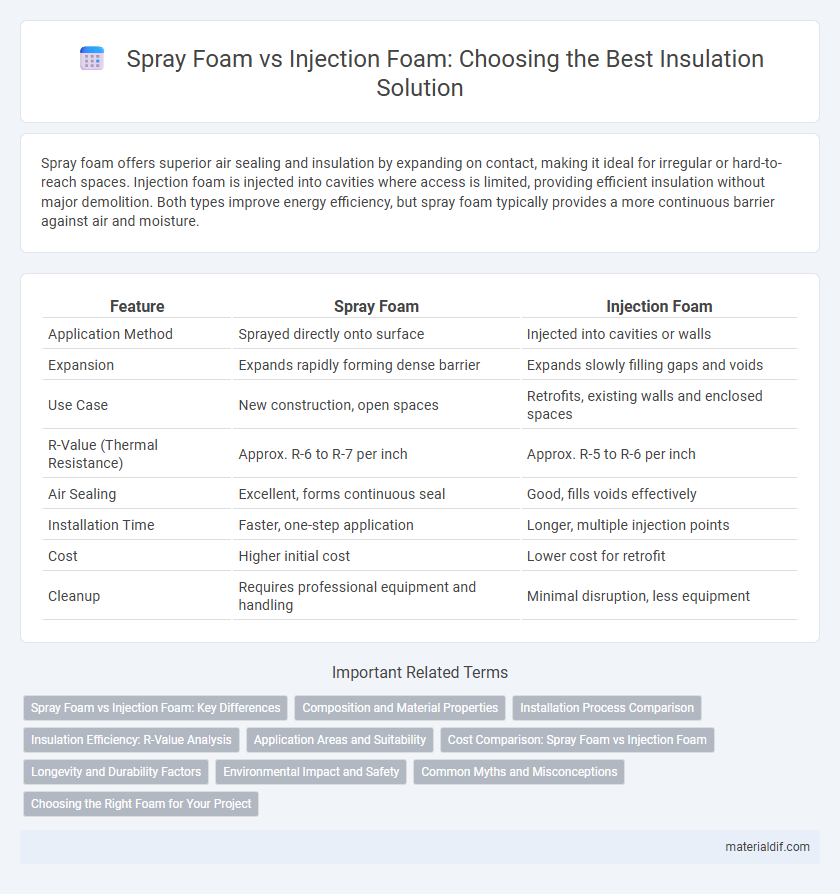

| Feature | Spray Foam | Injection Foam |

|---|---|---|

| Application Method | Sprayed directly onto surface | Injected into cavities or walls |

| Expansion | Expands rapidly forming dense barrier | Expands slowly filling gaps and voids |

| Use Case | New construction, open spaces | Retrofits, existing walls and enclosed spaces |

| R-Value (Thermal Resistance) | Approx. R-6 to R-7 per inch | Approx. R-5 to R-6 per inch |

| Air Sealing | Excellent, forms continuous seal | Good, fills voids effectively |

| Installation Time | Faster, one-step application | Longer, multiple injection points |

| Cost | Higher initial cost | Lower cost for retrofit |

| Cleanup | Requires professional equipment and handling | Minimal disruption, less equipment |

Spray Foam vs Injection Foam: Key Differences

Spray foam and injection foam differ primarily in application methods and material properties, with spray foam expanding rapidly upon application, filling cavities and providing a seamless insulation barrier, while injection foam is injected into existing walls or hard-to-reach areas for targeted insulation. Spray foam offers superior air sealing and moisture resistance, making it ideal for new construction, whereas injection foam is often used for retrofitting or improving insulation in older homes. The choice between the two depends on project goals, accessibility, and the need for comprehensive air sealing versus precise cavity filling.

Composition and Material Properties

Spray foam consists of expanding polyurethane or polyisocyanurate chemicals that form a rigid, closed-cell structure providing high insulation and air sealing properties. Injection foam uses similar chemistry but is formulated to be low-density and injectable, allowing it to fill cavities and hard-to-reach spaces with a semi-rigid or flexible foam. Both materials exhibit excellent thermal resistance and moisture barriers, but spray foam typically has higher compressive strength and a faster curing time compared to injection foam.

Installation Process Comparison

Spray foam insulation involves applying a liquid polymer that expands on contact, filling cavities rapidly and creating an air-tight seal ideal for irregular spaces. Injection foam, injected through small holes after drilling, is suited for retrofitting existing walls with minimal disruption, allowing precise control over foam placement. Both methods require professional equipment and trained installers, but spray foam typically demands more prep work while injection foam excels in targeted applications.

Insulation Efficiency: R-Value Analysis

Spray foam insulation typically offers higher R-values per inch, ranging from 6 to 7, compared to injection foam's average of 3.5 to 4.5, making spray foam more efficient in thermal resistance. The continuous, seamless application of spray foam reduces air leakage and enhances energy savings, whereas injection foam is often used for filling cavities with less coverage uniformity. Evaluating insulation projects requires considering the specific R-value requirements, installation method, and the building's thermal envelope.

Application Areas and Suitability

Spray foam excels in sealing large, irregular cavities and open spaces, making it ideal for attic insulation, wall cavities, and crawl spaces due to its expansive properties and quick curing time. Injection foam is best suited for confined or enclosed areas such as existing walls or rim joists where precise volume control and minimal disruption are critical. Both types offer excellent thermal insulation and air sealing, but selection hinges on the structural accessibility and specific sealing requirements of the application area.

Cost Comparison: Spray Foam vs Injection Foam

Spray foam insulation typically costs between $1.50 and $3.00 per square foot, offering a higher upfront investment but superior air sealing and R-value performance. Injection foam tends to be more affordable, averaging around $1.00 to $1.50 per square foot, making it a cost-effective choice for filling wall cavities without extensive demolition. Homeowners should weigh initial expenditure against long-term energy savings when comparing spray foam versus injection foam insulation.

Longevity and Durability Factors

Spray foam insulation typically offers superior longevity and durability due to its dense, closed-cell structure that resists moisture, air infiltration, and compressive forces over time. Injection foam, while effective for filling small cavities and cracks, generally has a lower lifespan and can degrade faster under high moisture or structural movement conditions. Choosing spray foam enhances long-term energy efficiency and structural integrity compared to injection foam applications.

Environmental Impact and Safety

Spray foam insulation uses chemicals like isocyanates and requires protective gear during application due to potential respiratory and skin irritation, while injection foam typically involves water-blown formulations with lower volatile organic compound (VOC) emissions, offering a safer option for indoor air quality. Both foams provide excellent thermal insulation, reducing energy consumption and greenhouse gas emissions, but injection foam tends to have a smaller environmental footprint during installation. Proper ventilation and adherence to safety protocols are crucial for minimizing health risks associated with spray foam chemicals.

Common Myths and Misconceptions

Spray foam and injection foam are often confused, but spray foam expands immediately upon application, providing air sealing and insulation, while injection foam expands more slowly to fill cavities in existing walls. A common myth is that spray foam is always better, but injection foam can be more effective in retrofitting older homes where wall openings are limited. Misconceptions include beliefs that both foams cause structural damage; however, when applied correctly, both are safe and enhance energy efficiency without harming building integrity.

Choosing the Right Foam for Your Project

Spray foam provides superior air sealing and insulation by expanding on application, making it ideal for irregular surfaces and comprehensive coverage in new construction or remodeling projects. Injection foam, designed to fill existing walls and cavities, is best suited for retrofitting and enhancing insulation without extensive demolition. Selecting between spray and injection foam depends on project requirements, accessibility, and desired insulation performance.

Spray Foam vs Injection Foam Infographic

materialdif.com

materialdif.com