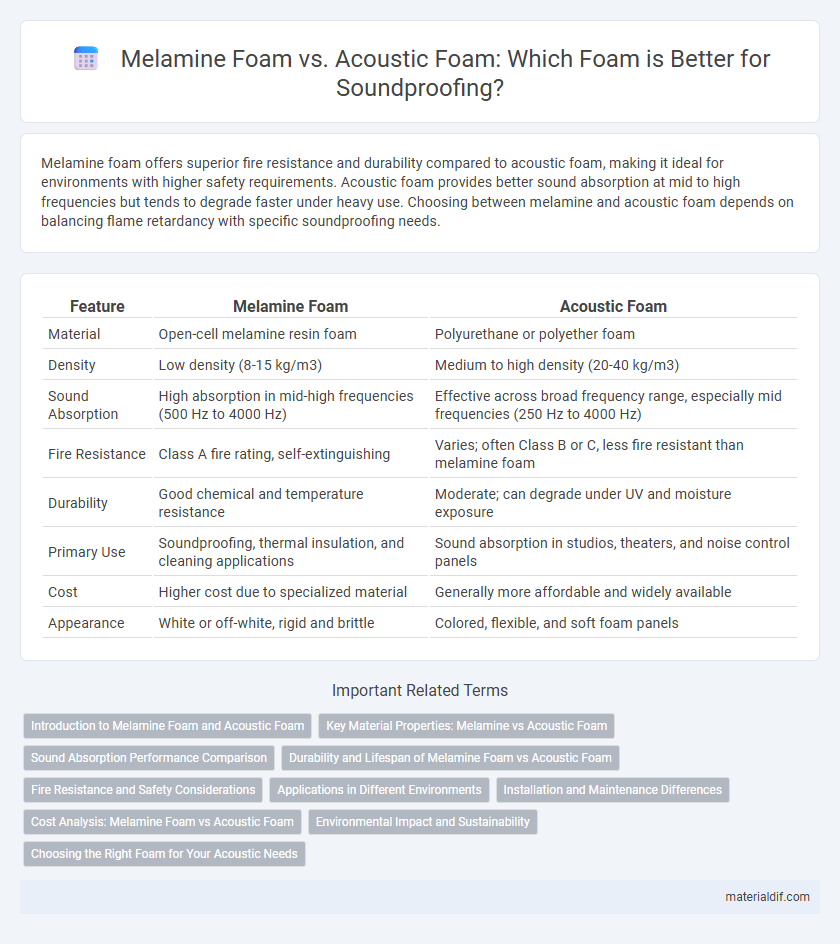

Melamine foam offers superior fire resistance and durability compared to acoustic foam, making it ideal for environments with higher safety requirements. Acoustic foam provides better sound absorption at mid to high frequencies but tends to degrade faster under heavy use. Choosing between melamine and acoustic foam depends on balancing flame retardancy with specific soundproofing needs.

Table of Comparison

| Feature | Melamine Foam | Acoustic Foam |

|---|---|---|

| Material | Open-cell melamine resin foam | Polyurethane or polyether foam |

| Density | Low density (8-15 kg/m3) | Medium to high density (20-40 kg/m3) |

| Sound Absorption | High absorption in mid-high frequencies (500 Hz to 4000 Hz) | Effective across broad frequency range, especially mid frequencies (250 Hz to 4000 Hz) |

| Fire Resistance | Class A fire rating, self-extinguishing | Varies; often Class B or C, less fire resistant than melamine foam |

| Durability | Good chemical and temperature resistance | Moderate; can degrade under UV and moisture exposure |

| Primary Use | Soundproofing, thermal insulation, and cleaning applications | Sound absorption in studios, theaters, and noise control panels |

| Cost | Higher cost due to specialized material | Generally more affordable and widely available |

| Appearance | White or off-white, rigid and brittle | Colored, flexible, and soft foam panels |

Introduction to Melamine Foam and Acoustic Foam

Melamine foam is a lightweight, open-cell material known for its excellent thermal insulation and sound absorption properties, commonly used in noise reduction applications and fire-resistant products. Acoustic foam, typically made from polyurethane or memory foam, is designed primarily to absorb sound waves and reduce echo in recording studios, theaters, and office environments. Both foams offer unique benefits in enhancing acoustic performance, with melamine foam excelling in heat resistance and acoustic foam providing superior sound dampening.

Key Material Properties: Melamine vs Acoustic Foam

Melamine foam features an open-cell structure with high thermal resistance, low density, and excellent fire retardant properties, making it suitable for insulation and sound absorption. Acoustic foam, typically made from polyurethane, offers greater flexibility and higher sound absorption coefficients at mid to high frequencies but has lower thermal resistance compared to melamine foam. Melamine foam's rigid matrix and superior chemical stability differentiate it from the softer, more porous structure of traditional acoustic foam used primarily in studio and architectural acoustics.

Sound Absorption Performance Comparison

Melamine foam exhibits superior sound absorption across a wider frequency range compared to traditional acoustic foam, particularly excelling in high-frequency attenuation due to its open-cell, rigid structure. Acoustic foam, often made from polyurethane, performs well in mid to high frequencies but can be less effective at lower frequencies without additional treatment. The density and pore size of melamine foam contribute to enhanced performance in reducing reverberation and echo, making it ideal for environments requiring precise acoustic control.

Durability and Lifespan of Melamine Foam vs Acoustic Foam

Melamine foam offers superior durability compared to traditional acoustic foam due to its rigid open-cell structure, which resists compression and maintains shape over time. Acoustic foam, typically made from polyurethane, tends to degrade faster under prolonged exposure to environmental factors such as humidity and UV light, resulting in reduced lifespan and effectiveness. Melamine foam's enhanced resilience makes it ideal for long-term acoustic treatments where consistent performance and minimal maintenance are critical.

Fire Resistance and Safety Considerations

Melamine foam offers superior fire resistance compared to traditional acoustic foam, as it is inherently non-combustible and meets stringent safety standards such as ASTM E84 Class A ratings. Acoustic foam, typically made from polyurethane, is more flammable and can release toxic fumes when burned, posing greater safety risks in enclosed environments. Choosing melamine foam enhances fire safety in applications requiring both sound absorption and stringent fire resistance compliance.

Applications in Different Environments

Melamine foam, known for its open-cell structure and fire-resistant properties, excels in environments requiring high thermal insulation and flame retardancy such as industrial settings and building insulation. Acoustic foam, typically made from polyurethane or polyether, is optimized for sound absorption in studios, theaters, and office spaces to reduce noise and improve sound quality. While melamine foam suits harsh, high-temperature locations, acoustic foam is preferred for controlled spaces needing noise control and reverberation reduction.

Installation and Maintenance Differences

Melamine foam requires minimal installation effort, often cut to size and placed without adhesives, making it suitable for temporary or flexible setups. Acoustic foam typically demands more precise mounting using glue, pins, or frames to ensure secure and stable positioning on walls or ceilings. Maintenance for melamine foam involves simple dusting or vacuuming, whereas acoustic foam may require more careful cleaning to preserve its delicate structure and sound-absorbing properties.

Cost Analysis: Melamine Foam vs Acoustic Foam

Melamine foam generally offers a cost-effective alternative to traditional acoustic foam, with prices typically lower due to its lightweight, open-cell structure and ease of production. Acoustic foam, often made from polyurethane, tends to be pricier but provides superior sound absorption across a wider frequency range, which may justify the higher initial investment for professional audio or industrial applications. Evaluating the total cost of ownership requires considering factors such as installation complexity, durability, and acoustic performance specific to the intended environment.

Environmental Impact and Sustainability

Melamine foam is derived from formaldehyde-based resin, which raises concerns over chemical emissions during production and disposal, whereas acoustic foam often consists of polyurethane, a petroleum-based product with limited biodegradability. Melamine foam offers better fire resistance and can be recycled or incinerated with lower harmful emissions, making it a more sustainable choice compared to traditional acoustic foams that tend to release toxic gases when burned. Choosing melamine foam enhances environmental sustainability by reducing reliance on fossil fuels and minimizing ecological footprint through improved durability and recyclability.

Choosing the Right Foam for Your Acoustic Needs

Melamine foam offers superior fire resistance, lightweight properties, and fine open-cell structure, making it ideal for high-temperature and sound absorption applications. Acoustic foam, typically made from polyurethane, provides effective mid to high-frequency sound dampening with varied thickness and density options to tailor soundproofing. Select melamine foam for environments demanding fire safety and thermal insulation, while acoustic foam suits studios and home theaters targeting broad frequency noise reduction.

Melamine Foam vs Acoustic Foam Infographic

materialdif.com

materialdif.com