Extruded foam offers a uniform cell structure and consistent density, making it ideal for applications requiring durability and moisture resistance. Molded foam provides superior flexibility and cushioning by expanding into complex shapes, suited for packaging and ergonomic products. Both types serve distinct purposes based on performance needs and manufacturing methods.

Table of Comparison

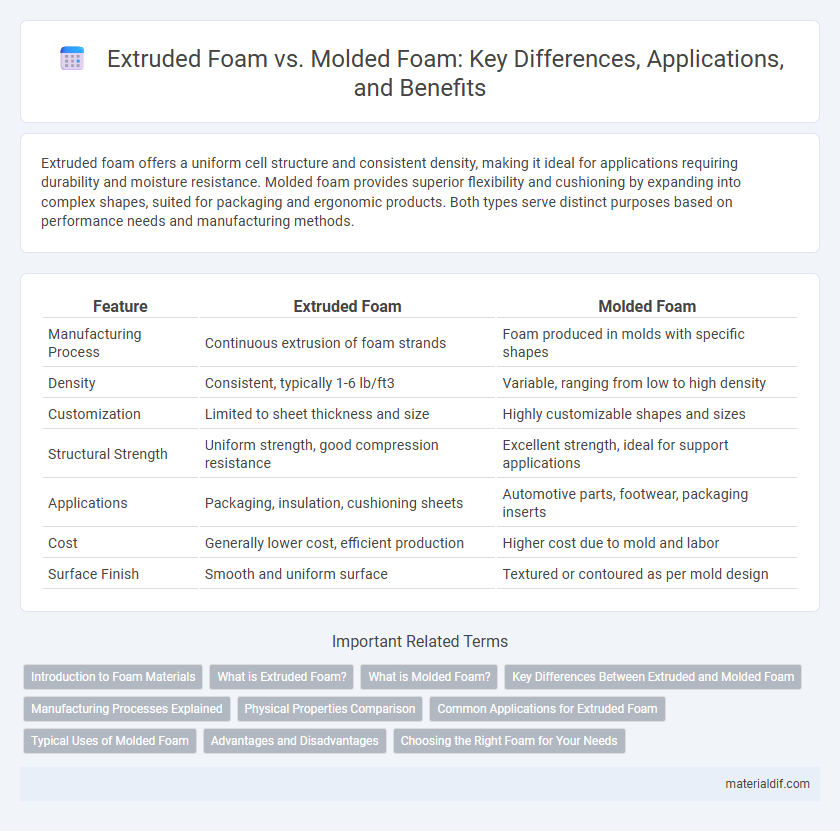

| Feature | Extruded Foam | Molded Foam |

|---|---|---|

| Manufacturing Process | Continuous extrusion of foam strands | Foam produced in molds with specific shapes |

| Density | Consistent, typically 1-6 lb/ft3 | Variable, ranging from low to high density |

| Customization | Limited to sheet thickness and size | Highly customizable shapes and sizes |

| Structural Strength | Uniform strength, good compression resistance | Excellent strength, ideal for support applications |

| Applications | Packaging, insulation, cushioning sheets | Automotive parts, footwear, packaging inserts |

| Cost | Generally lower cost, efficient production | Higher cost due to mold and labor |

| Surface Finish | Smooth and uniform surface | Textured or contoured as per mold design |

Introduction to Foam Materials

Extruded foam and molded foam are two primary types of foam materials widely used in insulation, packaging, and cushioning applications. Extruded foam is produced through a continuous process that creates a uniform, closed-cell structure, offering superior strength and moisture resistance. Molded foam, formed by pouring or injecting liquid foam into molds, is known for its versatility in shaping complex designs and providing excellent impact absorption.

What is Extruded Foam?

Extruded foam is a type of closed-cell foam produced by forcing melted polymer through a shaped die, creating a continuous, uniform sheet or board with consistent density and cell structure. Common materials used include polyethylene, polystyrene, and polypropylene, which provide excellent moisture resistance, thermal insulation, and impact absorption properties. This manufacturing process results in a durable foam ideal for packaging, insulation, and cushioning applications, offering superior strength and rigidity compared to molded foam.

What is Molded Foam?

Molded foam is a type of foam created by pouring liquid foam into a mold, allowing it to expand and solidify into specific shapes with high precision and intricate details. This foam production method yields durable, dense products commonly used in automotive components, insulation panels, and protective packaging. Molded foam offers superior flexibility in design and consistency compared to extruded foam, making it ideal for customized applications requiring complex geometries.

Key Differences Between Extruded and Molded Foam

Extruded foam is produced through a continuous extrusion process, resulting in a uniform cell structure and consistent density, making it ideal for applications requiring strength and durability, such as insulation and packaging. Molded foam is created by injecting foamable material into molds, allowing complex shapes and varied densities, commonly used in cushioning, automotive, and protective gear. Key differences include manufacturing methods, cell structure uniformity, density control, and suitability for specific applications where extruded foam excels in consistency and molded foam offers design flexibility.

Manufacturing Processes Explained

Extruded foam is produced through a continuous manufacturing process where raw materials are melted, mixed with blowing agents, and forced through a shaped die to create uniform sheets or profiles with consistent cell structure and density. Molded foam involves injecting or pouring polymer mixtures into molds, where chemical reactions and controlled expansion form complex shapes with customizable density and varying cell sizes. Both processes influence mechanical properties and applications, with extrusion excelling in lightweight, rigid panels and molding allowing intricate geometries and tailored cushioning.

Physical Properties Comparison

Extruded foam features a closed-cell structure with uniform density, offering superior compressive strength, water resistance, and thermal insulation compared to molded foam. Molded foam, often with an open-cell composition, provides greater cushioning and flexibility but typically has lower durability and moisture resistance. The physical properties make extruded foam ideal for structural applications, while molded foam suits comfort-focused uses.

Common Applications for Extruded Foam

Extruded foam is widely used in insulation for walls, roofs, and refrigeration due to its closed-cell structure that provides excellent thermal resistance and moisture resistance. It is also common in packaging, protecting delicate electronics and fragile items during shipping with its consistent density and impact absorption. Additionally, extruded foam serves in construction for soundproofing panels and expansion joints, offering durability and resistance to environmental factors.

Typical Uses of Molded Foam

Molded foam is widely utilized in automotive seating, protective packaging, and furniture cushions due to its ability to conform to complex shapes and provide consistent density. Its cushioning properties make it ideal for impact absorption in helmets and sports equipment. The manufacturing process allows for intricate designs and high durability, making molded foam a preferred choice for customized comfort and safety applications.

Advantages and Disadvantages

Extruded foam offers higher density and better structural integrity, making it ideal for insulation and packaging applications where durability is crucial. Molded foam provides superior customization and complex shapes at a lower cost but often has inconsistent density and reduced mechanical strength. Choosing between extruded and molded foam depends on specific needs for rigidity, shape complexity, and budget constraints.

Choosing the Right Foam for Your Needs

Extruded foam offers a consistent cell structure, higher density, and greater durability, making it ideal for applications requiring strength and moisture resistance such as insulation and packaging. Molded foam, known for its flexibility and cushioning properties, suits custom shapes and impact absorption, commonly used in protective cases and seating. Selecting the right foam depends on factors like load-bearing requirements, environmental exposure, and desired texture, ensuring optimal performance and longevity.

Extruded foam vs Molded foam Infographic

materialdif.com

materialdif.com