Acoustic foam is specifically designed to absorb sound waves and reduce noise, making it ideal for studios and soundproofing applications. Packaging foam prioritizes cushioning and protection to safeguard fragile items during shipping, with properties tailored for impact resistance rather than sound absorption. Choosing between the two depends on whether the primary need is noise control or product protection.

Table of Comparison

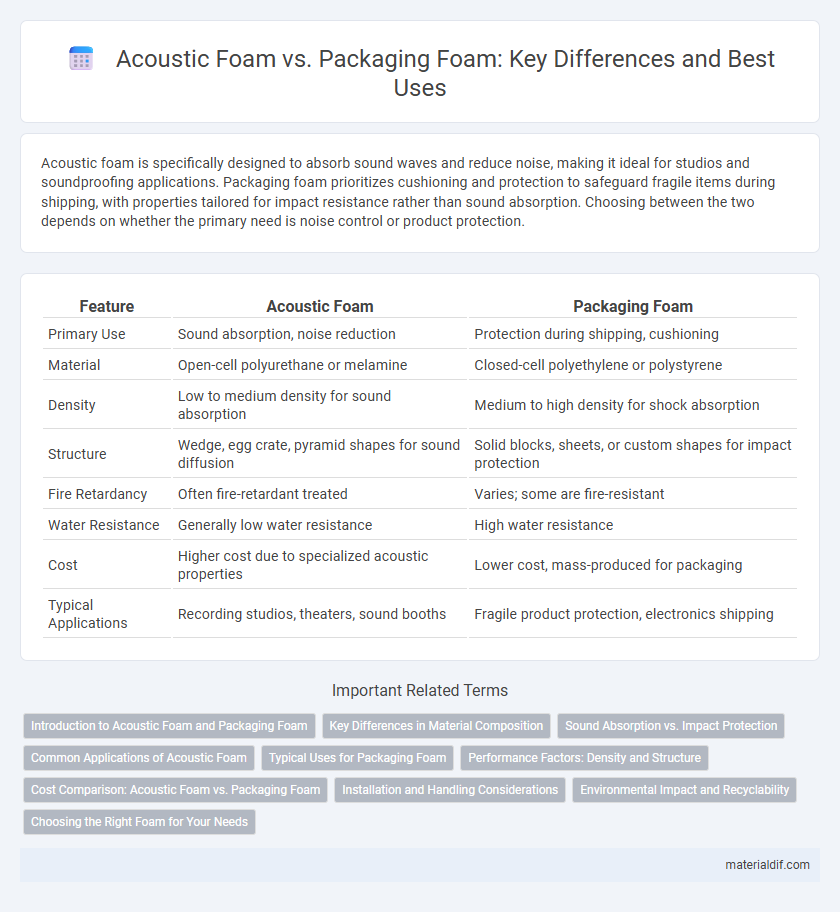

| Feature | Acoustic Foam | Packaging Foam |

|---|---|---|

| Primary Use | Sound absorption, noise reduction | Protection during shipping, cushioning |

| Material | Open-cell polyurethane or melamine | Closed-cell polyethylene or polystyrene |

| Density | Low to medium density for sound absorption | Medium to high density for shock absorption |

| Structure | Wedge, egg crate, pyramid shapes for sound diffusion | Solid blocks, sheets, or custom shapes for impact protection |

| Fire Retardancy | Often fire-retardant treated | Varies; some are fire-resistant |

| Water Resistance | Generally low water resistance | High water resistance |

| Cost | Higher cost due to specialized acoustic properties | Lower cost, mass-produced for packaging |

| Typical Applications | Recording studios, theaters, sound booths | Fragile product protection, electronics shipping |

Introduction to Acoustic Foam and Packaging Foam

Acoustic foam is designed to absorb sound waves and reduce noise pollution, commonly used in recording studios and soundproof rooms. Packaging foam provides cushioning and protection to fragile items during shipping and handling, preventing damage from impacts. Both types of foam serve distinct purposes based on their density, structure, and material properties.

Key Differences in Material Composition

Acoustic foam is primarily made from open-cell polyurethane or melamine resin designed to absorb sound waves and reduce noise, featuring a porous structure that enhances soundproofing. Packaging foam often consists of closed-cell materials such as polyethylene or polystyrene, engineered to provide cushioning and shock absorption for protecting goods during shipping. The key difference lies in the cell structure and density, where acoustic foam prioritizes sound absorption properties, while packaging foam emphasizes impact resistance and durability.

Sound Absorption vs. Impact Protection

Acoustic foam excels in sound absorption by reducing echo and reverberation through its open-cell structure that traps sound waves, making it ideal for recording studios and home theaters. In contrast, packaging foam prioritizes impact protection with a denser composition designed to cushion and protect fragile items during shipping and handling. While acoustic foam minimizes noise pollution, packaging foam safeguards physical integrity, highlighting distinct functionalities based on foam design and material properties.

Common Applications of Acoustic Foam

Acoustic foam is primarily used in soundproofing applications such as recording studios, home theaters, and office spaces to reduce echo and improve sound quality by absorbing sound waves. Unlike packaging foam, which protects fragile items during shipping by cushioning impacts, acoustic foam focuses on controlling noise and enhancing audio clarity. Key applications include wall panels, ceiling tiles, and bass traps designed specifically to manage sound reflections and reverberations.

Typical Uses for Packaging Foam

Packaging foam is primarily used for cushioning and protecting fragile items during shipping and storage, preventing damage from impact, vibration, and compression. It is commonly found in boxes, crates, and custom inserts tailored to fit specific products such as electronics, glassware, and medical devices. Unlike acoustic foam, which aims to absorb sound waves and reduce noise, packaging foam focuses on maintaining product integrity and enhancing safety throughout transportation.

Performance Factors: Density and Structure

Acoustic foam features a low-density, open-cell structure designed to absorb sound waves and reduce noise reflections, optimizing soundproofing performance. Packaging foam typically has a higher density with a closed-cell structure that provides superior shock absorption and cushioning to protect fragile items during transit. Density and cellular structure directly influence the functional efficiency of foam in acoustic insulation versus impact protection applications.

Cost Comparison: Acoustic Foam vs. Packaging Foam

Acoustic foam typically costs more per square foot than packaging foam due to its specialized sound-absorbing properties and higher density materials. Packaging foam is generally more affordable, designed primarily for cushioning and protection during shipping rather than acoustic performance. Budget considerations often drive the choice, with acoustic foam favored for soundproofing despite the higher initial investment compared to packaging foam.

Installation and Handling Considerations

Acoustic foam requires precise cutting and careful placement to maximize sound absorption and minimize gaps, often necessitating adhesive sprays or mounting brackets for secure installation. Packaging foam emphasizes flexibility and cushioning, typically featuring easy-to-cut sheets or pre-formed shapes that conform to product contours for efficient handling. Both types demand careful handling to maintain material integrity, but acoustic foam installations tend to be more labor-intensive due to the need for exact fit and alignment.

Environmental Impact and Recyclability

Acoustic foam often contains polyurethane or melamine, materials that pose challenges in recycling due to their chemical composition and can emit volatile organic compounds (VOCs) during production and disposal, impacting air quality. Packaging foam, commonly made from expanded polystyrene (EPS), is notorious for its persistence in the environment, contributing significantly to landfill volume and marine pollution, though some advanced recycling programs are emerging. Both types of foam require improved end-of-life management strategies to minimize ecological footprints and enhance circular economy potential.

Choosing the Right Foam for Your Needs

Acoustic foam is designed to absorb sound waves and reduce noise, making it ideal for studios, theaters, and offices, whereas packaging foam provides cushioning and protection for fragile items during transport. Selecting the right foam depends on specific requirements such as soundproofing efficiency or impact resistance; acoustic foam typically features open-cell structures to trap sound, while packaging foam uses closed-cell materials for shock absorption. Understanding these functional differences ensures optimal performance and cost-effectiveness in applications ranging from sound control to product shipping.

Acoustic foam vs Packaging foam Infographic

materialdif.com

materialdif.com