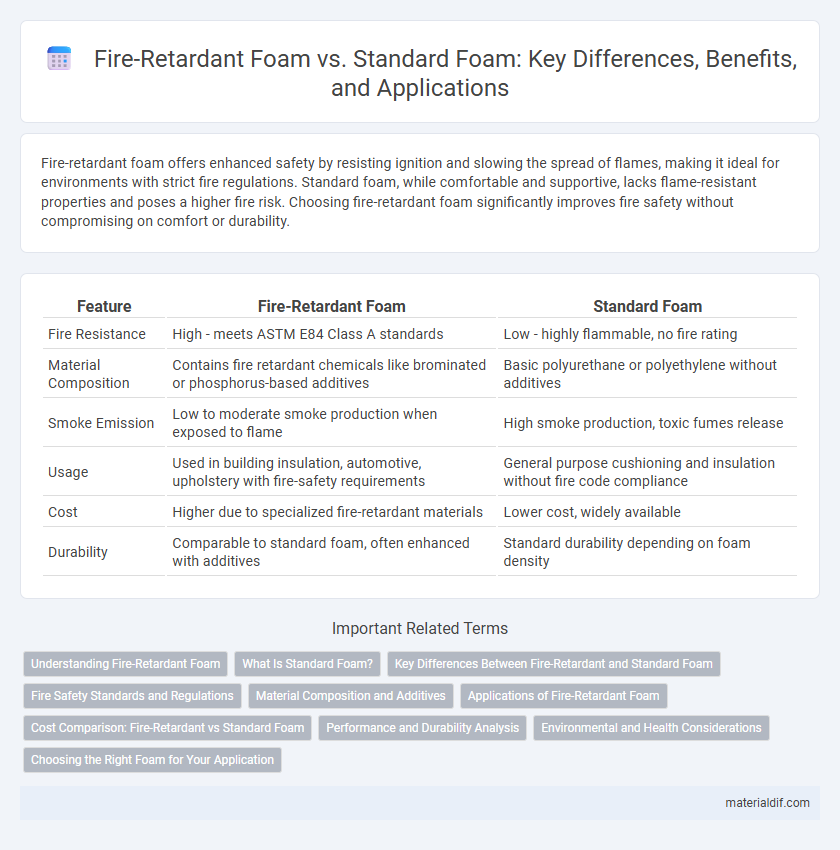

Fire-retardant foam offers enhanced safety by resisting ignition and slowing the spread of flames, making it ideal for environments with strict fire regulations. Standard foam, while comfortable and supportive, lacks flame-resistant properties and poses a higher fire risk. Choosing fire-retardant foam significantly improves fire safety without compromising on comfort or durability.

Table of Comparison

| Feature | Fire-Retardant Foam | Standard Foam |

|---|---|---|

| Fire Resistance | High - meets ASTM E84 Class A standards | Low - highly flammable, no fire rating |

| Material Composition | Contains fire retardant chemicals like brominated or phosphorus-based additives | Basic polyurethane or polyethylene without additives |

| Smoke Emission | Low to moderate smoke production when exposed to flame | High smoke production, toxic fumes release |

| Usage | Used in building insulation, automotive, upholstery with fire-safety requirements | General purpose cushioning and insulation without fire code compliance |

| Cost | Higher due to specialized fire-retardant materials | Lower cost, widely available |

| Durability | Comparable to standard foam, often enhanced with additives | Standard durability depending on foam density |

Understanding Fire-Retardant Foam

Fire-retardant foam contains chemical additives that significantly reduce its flammability by creating a barrier to slow down ignition and combustion, unlike standard foam which lacks these fire-resistant properties. This specialized foam is commonly used in construction, automotive, and upholstery industries to enhance fire safety and meet regulatory compliance standards. Incorporating fire-retardant foam helps minimize fire hazards, improve occupant safety, and protect property from rapid fire spread.

What Is Standard Foam?

Standard foam is a versatile, lightweight material composed primarily of polyurethane or polyethylene used for cushioning, insulation, and packaging applications. It lacks inherent fire-retardant properties, making it more susceptible to ignition and rapid flame spread compared to fire-retardant variants. Standard foam is cost-effective and widely utilized in furniture, bedding, and automotive industries where stringent fire safety standards are not mandatory.

Key Differences Between Fire-Retardant and Standard Foam

Fire-retardant foam contains chemical additives that significantly reduce flammability and slow the spread of flames, unlike standard foam which lacks these fire-resistant properties. The thermal stability of fire-retardant foam allows it to withstand higher temperatures without combusting, making it ideal for fire safety applications in construction and furniture. Standard foam typically offers better cushioning and flexibility but compromises on fire resistance, limiting its use where fire codes are stringent.

Fire Safety Standards and Regulations

Fire-retardant foam meets stringent fire safety standards such as ASTM E84 and BS 5852, ensuring reduced flammability and slower ignition compared to standard foam. These foams contain chemical additives that inhibit combustion, helping buildings comply with local fire codes like NFPA 101 Life Safety Code and EN 13501-1. Standard foam lacks these fire-retardant properties, often failing to meet rigorous regulatory requirements for use in public and commercial spaces.

Material Composition and Additives

Fire-retardant foam contains specialized chemical additives such as halogenated compounds, phosphorus-based flame retardants, or intumescent agents that inhibit combustion and reduce flammability, unlike standard foam which primarily consists of polyurethane or polyethylene without these fire-resistant components. The material composition of fire-retardant foam is engineered to enhance thermal stability and delay ignition, often incorporating expanded graphite or alumina trihydrate to promote char formation and suppress flames. Standard foam lacks these modifications, resulting in higher flammability and faster burn rates under exposure to heat or flames.

Applications of Fire-Retardant Foam

Fire-retardant foam is extensively used in construction, insulation, and industrial settings due to its enhanced ability to resist ignition and slow fire spread. This foam is especially crucial in environments requiring stringent safety standards, such as chemical plants, warehouses, and transportation sectors. Its fire-resistant properties ensure compliance with fire safety regulations, reducing property damage and improving occupant safety compared to standard foam applications.

Cost Comparison: Fire-Retardant vs Standard Foam

Fire-retardant foam generally costs 15-30% more than standard foam due to added chemical treatments enhancing its resistance to ignition and flame spread. While the upfront price is higher, fire-retardant foam can reduce long-term expenses by minimizing fire damage and improving safety compliance in commercial and residential buildings. Standard foam remains a budget-friendly option but lacks the enhanced safety features critical for high-risk environments.

Performance and Durability Analysis

Fire-retardant foam exhibits superior performance in resisting ignition and slowing flame spread compared to standard foam, which is more prone to combustion and rapid degradation. The enhanced chemical additives in fire-retardant foam improve thermal stability, maintaining structural integrity under high temperatures for extended periods. Durability tests show fire-retardant foam retains its cushioning properties longer in fire-prone environments, making it ideal for safety-critical applications.

Environmental and Health Considerations

Fire-retardant foam contains chemical additives that enhance flame resistance but may release toxic fumes during combustion, posing health risks and potential environmental hazards. Standard foam, while less resistant to fire, typically lacks these hazardous additives, resulting in lower toxic emissions but increased flammability. Evaluating foam for applications requires balancing fire safety benefits against potential environmental impact and long-term exposure risks to humans and wildlife.

Choosing the Right Foam for Your Application

Fire-retardant foam offers enhanced safety by resisting ignition and slowing flame spread, making it ideal for applications requiring stringent fire safety standards, such as insulation in buildings or protective packaging for electronics. Standard foam provides effective cushioning and insulation but lacks specialized fire-resistant properties, suitable for general-purpose use where fire risk is minimal. Selecting the right foam depends on evaluating the environment, potential fire hazards, and regulatory requirements to ensure both performance and safety compliance.

Fire-Retardant Foam vs Standard Foam Infographic

materialdif.com

materialdif.com