Polyurethane foam offers superior flexibility, higher durability, and better insulation properties compared to polystyrene foam, making it ideal for applications requiring cushioning and thermal resistance. In contrast, polystyrene foam is lightweight, cost-effective, and provides excellent moisture resistance, commonly used in packaging and insulation panels. Choosing between polyurethane and polystyrene foam depends on the specific needs for strength, flexibility, and environmental exposure.

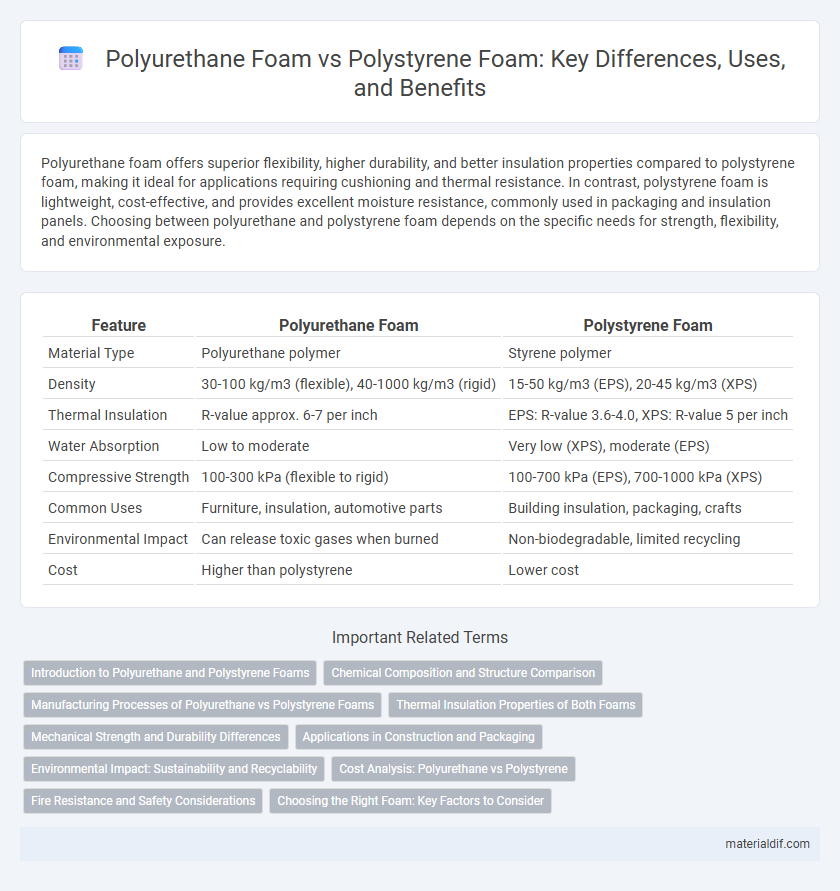

Table of Comparison

| Feature | Polyurethane Foam | Polystyrene Foam |

|---|---|---|

| Material Type | Polyurethane polymer | Styrene polymer |

| Density | 30-100 kg/m3 (flexible), 40-1000 kg/m3 (rigid) | 15-50 kg/m3 (EPS), 20-45 kg/m3 (XPS) |

| Thermal Insulation | R-value approx. 6-7 per inch | EPS: R-value 3.6-4.0, XPS: R-value 5 per inch |

| Water Absorption | Low to moderate | Very low (XPS), moderate (EPS) |

| Compressive Strength | 100-300 kPa (flexible to rigid) | 100-700 kPa (EPS), 700-1000 kPa (XPS) |

| Common Uses | Furniture, insulation, automotive parts | Building insulation, packaging, crafts |

| Environmental Impact | Can release toxic gases when burned | Non-biodegradable, limited recycling |

| Cost | Higher than polystyrene | Lower cost |

Introduction to Polyurethane and Polystyrene Foams

Polyurethane foam consists of flexible or rigid polymers formed by reacting polyols with isocyanates, offering superior insulation and cushioning properties for various applications. Polystyrene foam, made from polymerized styrene monomers, is lightweight and provides excellent thermal insulation and moisture resistance, commonly used in packaging and building materials. Both foams differ significantly in structure, density, and performance characteristics, influencing their specific industrial and consumer uses.

Chemical Composition and Structure Comparison

Polyurethane foam consists of polymer chains formed by reacting diisocyanates with polyols, creating a flexible and open-cell structure with excellent cushioning properties. Polystyrene foam is made from polystyrene beads expanded and fused into a rigid, closed-cell foam with high compressive strength and thermal insulation. The chemical composition differences result in polyurethane being more versatile and flexible, while polystyrene offers superior rigidity and moisture resistance.

Manufacturing Processes of Polyurethane vs Polystyrene Foams

Polyurethane foam is produced through a chemical reaction between polyols and diisocyanates, resulting in a versatile foam that can be tailored for flexibility or rigidity. Polystyrene foam manufacturing involves polymerizing styrene monomers into beads, which are then expanded and molded using steam to create lightweight, rigid foam structures. The polyurethane process offers greater customization in density and elasticity, while polystyrene emphasizes uniformity and thermal insulation properties.

Thermal Insulation Properties of Both Foams

Polyurethane foam offers superior thermal insulation performance due to its low thermal conductivity, typically around 0.02 W/m*K, making it highly effective for reducing heat transfer. Polystyrene foam, including expanded (EPS) and extruded (XPS) types, generally has higher thermal conductivity values, ranging from 0.03 to 0.04 W/m*K, resulting in slightly less insulation efficiency. The closed-cell structure of polyurethane foam enhances its ability to resist heat flow, providing better energy savings in building insulation applications compared to polystyrene foam.

Mechanical Strength and Durability Differences

Polyurethane foam exhibits superior mechanical strength compared to polystyrene foam, making it better suited for applications requiring high load-bearing capacity and resistance to deformation. Polystyrene foam, while lightweight and cost-effective, tends to have lower impact resistance and is more prone to brittleness over time. Durability assessments show polyurethane foam maintains structural integrity longer under repeated stress and environmental exposure, whereas polystyrene foam may degrade faster due to its rigid molecular structure.

Applications in Construction and Packaging

Polyurethane foam offers superior insulation properties and flexibility, making it ideal for thermal insulation in walls, roofs, and structural panels in construction. Polystyrene foam, especially expanded polystyrene (EPS), excels in lightweight packaging materials and protective cushioning due to its shock absorption and moisture resistance. Both foams are widely used but serve distinct roles: polyurethane for energy efficiency and comfort in buildings, polystyrene for cost-effective, durable packaging solutions.

Environmental Impact: Sustainability and Recyclability

Polyurethane foam, derived from petrochemicals, presents challenges in recyclability due to its complex chemical structure, often resulting in landfill accumulation and environmental persistence. Polystyrene foam, while also petroleum-based, has slightly better recycling pathways through mechanical recycling but suffers from low recycling rates and significant litter issues in natural habitats. Both foams contribute to ecological concerns, with ongoing research aimed at enhancing biodegradability and developing sustainable alternatives to reduce their environmental footprint.

Cost Analysis: Polyurethane vs Polystyrene

Polyurethane foam generally incurs higher production costs compared to polystyrene due to its complex chemical synthesis and enhanced durability properties. Polystyrene foam, being less expensive to manufacture, offers a cost-effective option for insulation and packaging applications but may lack the long-term resilience of polyurethane. Evaluating total expenses involves considering polyurethane's superior insulation efficiency and lifespan against polystyrene's initial affordability.

Fire Resistance and Safety Considerations

Polyurethane foam has lower fire resistance compared to polystyrene foam, as it ignites more easily and releases toxic gases when burned, necessitating stringent fire safety measures. Polystyrene foam, especially when treated with fire retardants, offers better resistance to ignition and slows flame spread, making it a safer option in fire-prone environments. Building codes often favor polystyrene foam for insulation due to its superior fire safety profile and reduced smoke toxicity during combustion.

Choosing the Right Foam: Key Factors to Consider

Polyurethane foam offers superior insulation and flexibility, ideal for applications requiring cushioning and energy absorption, while polystyrene foam excels in rigidity and moisture resistance, making it suitable for structural support and packaging. Consider thermal conductivity values, density, and environmental impact to ensure optimal performance and sustainability in your project. Cost-effectiveness and specific use-case requirements will guide the choice between the lightweight, versatile polyurethane and the durable, moisture-resistant polystyrene foam.

Polyurethane foam vs Polystyrene foam Infographic

materialdif.com

materialdif.com