Flame-retardant foam is engineered with chemical additives to resist ignition and slow the spread of fire, enhancing safety in various applications such as furniture and insulation. Standard foam, while affordable and versatile, lacks these fire-resistant properties, making it more susceptible to burning and producing hazardous smoke. Choosing flame-retardant foam improves compliance with fire safety regulations and reduces potential fire-related risks in residential and commercial environments.

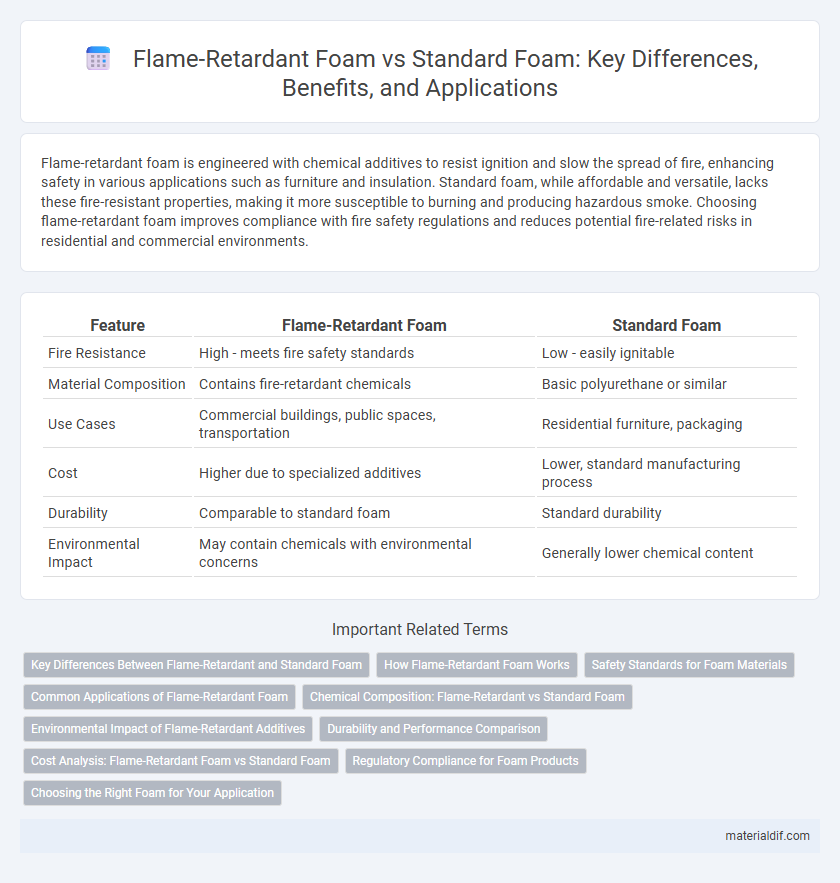

Table of Comparison

| Feature | Flame-Retardant Foam | Standard Foam |

|---|---|---|

| Fire Resistance | High - meets fire safety standards | Low - easily ignitable |

| Material Composition | Contains fire-retardant chemicals | Basic polyurethane or similar |

| Use Cases | Commercial buildings, public spaces, transportation | Residential furniture, packaging |

| Cost | Higher due to specialized additives | Lower, standard manufacturing process |

| Durability | Comparable to standard foam | Standard durability |

| Environmental Impact | May contain chemicals with environmental concerns | Generally lower chemical content |

Key Differences Between Flame-Retardant and Standard Foam

Flame-retardant foam contains chemical additives that significantly reduce its flammability, meeting strict fire safety standards such as California TB117-2013, while standard foam lacks these treatments and can ignite more easily. The enhanced fire resistance of flame-retardant foam is critical in applications like upholstery and bedding, where compliance with fire codes ensures safer environments. Standard foam is typically less expensive and offers similar comfort properties but is unsuitable for regulated settings due to its higher fire risk.

How Flame-Retardant Foam Works

Flame-retardant foam contains chemical additives that inhibit or resist the spread of fire by disrupting the combustion process at the molecular level. These additives, such as brominated or phosphorus-based compounds, release non-flammable gases or create a protective char layer when exposed to heat, reducing oxygen availability to flames. The advanced formulation of flame-retardant foam significantly enhances fire safety by slowing ignition and flame propagation compared to standard foam.

Safety Standards for Foam Materials

Flame-retardant foam complies with strict fire safety standards such as California TB117-2013 and BS 5852, significantly reducing flammability risks compared to standard foam. These specialized foams are treated with chemical additives that inhibit ignition and slow flame spread, enhancing overall safety in upholstery and bedding applications. Standard foam lacks these treatments, making it more susceptible to catching fire and failing to meet rigorous safety certifications required for commercial and residential use.

Common Applications of Flame-Retardant Foam

Flame-retardant foam is extensively used in upholstery, bedding, and automotive interiors to enhance fire safety by meeting strict regulatory standards. It is also common in public transportation seating, theater seating, and office furniture where fire-resistant materials are mandated. These applications benefit from the foam's ability to resist ignition and slow the spread of flames compared to standard foam, ensuring increased occupant protection.

Chemical Composition: Flame-Retardant vs Standard Foam

Flame-retardant foam contains specialized chemical additives such as halogenated compounds, phosphorus-based agents, or metal hydroxides that inhibit ignition and slow combustion, enhancing fire resistance. In contrast, standard foam primarily consists of polyurethane or polyethylene without these fire-resistant chemicals, making it more susceptible to rapid ignition and burning. The inclusion of flame-retardant chemicals alters the foam's molecular structure, increasing its thermal stability and reducing smoke production during exposure to flames.

Environmental Impact of Flame-Retardant Additives

Flame-retardant foam contains chemical additives such as brominated or chlorinated compounds that can persist in the environment and potentially bioaccumulate in wildlife. These additives contribute to increased toxicity in soil and water, posing risks to ecosystems and human health. In contrast, standard foam generally lacks these harmful flame-retardant chemicals, resulting in a lower environmental footprint during production, use, and disposal.

Durability and Performance Comparison

Flame-retardant foam offers enhanced durability by resisting ignition and slowing flame spread, significantly improving safety in fire-prone environments compared to standard foam. Its chemical composition maintains structural integrity longer under heat exposure, ensuring sustained performance where thermal resistance is crucial. Standard foam tends to degrade faster under fire conditions, compromising both longevity and safety.

Cost Analysis: Flame-Retardant Foam vs Standard Foam

Flame-retardant foam typically incurs higher upfront costs compared to standard foam due to specialized chemical additives that enhance fire resistance and compliance with strict safety regulations. Long-term cost analysis shows flame-retardant foam can reduce expenses related to fire damage repairs, insurance premiums, and regulatory fines, potentially offsetting the initial investment. Standard foam may offer initial savings but poses greater financial risks in fire-prone applications, impacting overall cost-effectiveness.

Regulatory Compliance for Foam Products

Flame-retardant foam complies with strict fire safety regulations such as California Technical Bulletin 117-2013 and the UK Furniture and Furnishings (Fire) (Safety) Regulations 1988, ensuring reduced flammability and enhanced occupant safety. Standard foam typically lacks these certifications, posing higher risks in residential and commercial applications. Regulatory compliance in flame-retardant foam is critical for meeting legal standards and passing safety inspections in industries including furniture manufacturing and automotive seating.

Choosing the Right Foam for Your Application

Flame-retardant foam contains chemical additives that reduce flammability and slow the spread of fire, making it ideal for applications requiring enhanced safety standards such as upholstery, insulation, and automotive interiors. Standard foam, while more cost-effective and offering good cushioning and support, lacks these fire-resistant properties and is best suited for non-hazardous environments. Selecting the right foam depends on specific needs for fire safety, regulatory compliance, and performance requirements in your application.

Flame-Retardant Foam vs Standard Foam Infographic

materialdif.com

materialdif.com