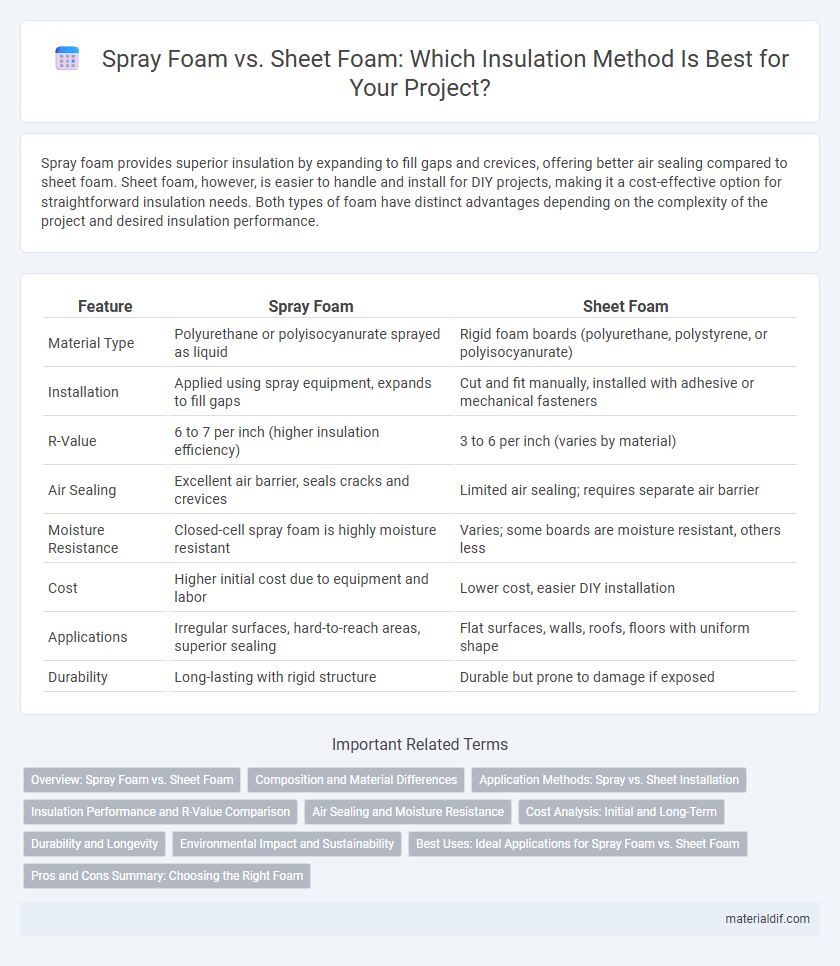

Spray foam provides superior insulation by expanding to fill gaps and crevices, offering better air sealing compared to sheet foam. Sheet foam, however, is easier to handle and install for DIY projects, making it a cost-effective option for straightforward insulation needs. Both types of foam have distinct advantages depending on the complexity of the project and desired insulation performance.

Table of Comparison

| Feature | Spray Foam | Sheet Foam |

|---|---|---|

| Material Type | Polyurethane or polyisocyanurate sprayed as liquid | Rigid foam boards (polyurethane, polystyrene, or polyisocyanurate) |

| Installation | Applied using spray equipment, expands to fill gaps | Cut and fit manually, installed with adhesive or mechanical fasteners |

| R-Value | 6 to 7 per inch (higher insulation efficiency) | 3 to 6 per inch (varies by material) |

| Air Sealing | Excellent air barrier, seals cracks and crevices | Limited air sealing; requires separate air barrier |

| Moisture Resistance | Closed-cell spray foam is highly moisture resistant | Varies; some boards are moisture resistant, others less |

| Cost | Higher initial cost due to equipment and labor | Lower cost, easier DIY installation |

| Applications | Irregular surfaces, hard-to-reach areas, superior sealing | Flat surfaces, walls, roofs, floors with uniform shape |

| Durability | Long-lasting with rigid structure | Durable but prone to damage if exposed |

Overview: Spray Foam vs. Sheet Foam

Spray foam insulation expands upon application, creating an air-tight seal that enhances thermal resistance and reduces energy loss, making it ideal for irregular or hard-to-reach areas. Sheet foam, commonly available as rigid panels, offers consistent thickness and structural support, providing excellent insulation and moisture resistance in walls and roofs. Both materials differ in installation methods, with spray foam requiring professional spraying techniques while sheet foam can be cut and fitted manually, influencing project cost and time.

Composition and Material Differences

Spray foam consists of polyurethane components that expand upon application, filling gaps and creating a seamless insulation layer, while sheet foam is typically made from rigid polystyrene or polyisocyanurate panels providing structured, dense thermal barriers. The chemical composition of spray foam involves a two-part mixture that reacts to form a closed-cell or open-cell foam, offering excellent air sealing properties, whereas sheet foam relies on its physical density and layering to resist heat transfer and moisture. Material differences influence installation methods and performance, with spray foam adapting to irregular shapes and sheet foam requiring precise cutting and fitting for effective insulation.

Application Methods: Spray vs. Sheet Installation

Spray foam is applied as a liquid that rapidly expands upon contact, allowing it to fill irregular spaces and create an airtight seal, making it ideal for insulation in complex or hard-to-reach areas. Sheet foam comes in pre-cut panels or rolls that are manually installed, requiring precise measurements and fitting, suitable for flat or uniform surfaces. The choice between spray foam and sheet foam installation depends on project complexity, surface contours, and the desired level of insulation performance.

Insulation Performance and R-Value Comparison

Spray foam insulation offers superior sealing capabilities and a higher R-value per inch, typically ranging from 6 to 7, compared to sheet foam's R-value of about 3 to 5 per inch, enhancing thermal resistance and energy efficiency. The expanding nature of spray foam fills gaps and irregular cavities, reducing air leakage and improving overall insulation performance. Sheet foam provides consistent thickness and ease of installation but may require additional air sealing measures to match the insulating effectiveness of spray foam applications.

Air Sealing and Moisture Resistance

Spray foam provides superior air sealing by expanding to fill gaps and cracks, creating an airtight barrier that prevents air leakage more effectively than sheet foam. Its moisture resistance is enhanced by its seamless application, which reduces the risk of water infiltration and mold growth. Sheet foam, while easier to install, often requires additional sealing measures to achieve comparable air-tightness and moisture protection.

Cost Analysis: Initial and Long-Term

Spray foam insulation has a higher initial cost, averaging $1.50 to $3.00 per square foot, but offers superior air sealing and energy efficiency, resulting in significant long-term savings on heating and cooling bills. Sheet foam, such as rigid foam boards, typically costs between $0.50 and $2.00 per square foot initially, making it more affordable upfront but less effective at reducing energy costs over time. Investing in spray foam often leads to lower total expenses over the lifespan of the insulation due to reduced energy consumption and improved durability.

Durability and Longevity

Spray foam insulation offers superior durability due to its ability to expand and seal gaps, preventing moisture infiltration and reducing the risk of mold, which enhances the longevity of the structure. Sheet foam, while easier to install, typically lacks the same air-sealing capability and can be more prone to physical damage over time, affecting its long-term performance. Choosing spray foam ensures a more robust and lasting insulation solution, especially in environments subject to temperature fluctuations and moisture exposure.

Environmental Impact and Sustainability

Spray foam insulation typically contains chemicals like isocyanates and HFCs that contribute to ozone depletion and high global warming potential, whereas sheet foam, often made from recyclable materials such as polystyrene or polyethylene, offers better sustainability through easier recycling processes. Spray foam's expansion properties create an effective air seal but complicate disposal, leading to environmental concerns in waste management. Sheet foam panels, with lower embodied energy and improved end-of-life recyclability, present a more eco-friendly alternative, supporting green building certifications and reducing carbon footprint.

Best Uses: Ideal Applications for Spray Foam vs. Sheet Foam

Spray foam excels in sealing irregular gaps and providing superior insulation in walls, roofs, and crawl spaces due to its expanding properties and air barrier capabilities. Sheet foam, often made of rigid panels like polystyrene or polyisocyanurate, is best suited for flat surfaces such as under siding, flooring, and exterior sheathing, offering consistent thickness and high compressive strength. Choosing spray foam is ideal for detailed, hard-to-reach areas requiring airtight seals, while sheet foam is optimal for structural insulation where uniform coverage and load resistance are critical.

Pros and Cons Summary: Choosing the Right Foam

Spray foam offers superior insulation with excellent air sealing, making it ideal for irregular and hard-to-reach areas, but it can be more expensive and requires professional installation. Sheet foam, also known as rigid foam board, provides consistent thickness and is easier for DIY projects, yet it may leave gaps and does not expand to fill cavities completely. Selecting the right foam depends on budget, application area, and insulation needs, balancing cost, installation complexity, and performance.

Spray foam vs Sheet foam Infographic

materialdif.com

materialdif.com