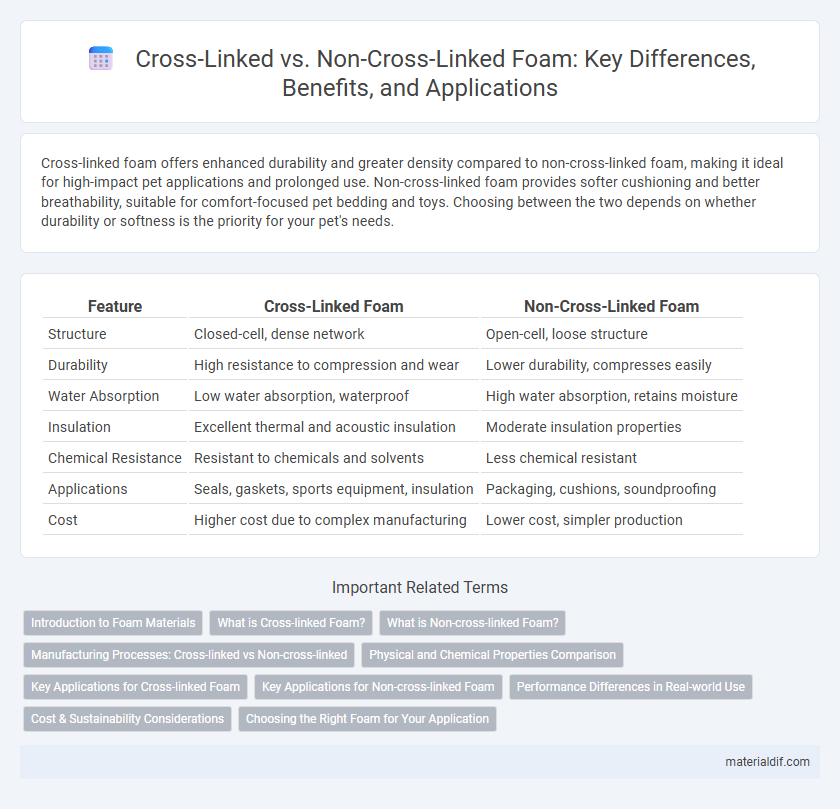

Cross-linked foam offers enhanced durability and greater density compared to non-cross-linked foam, making it ideal for high-impact pet applications and prolonged use. Non-cross-linked foam provides softer cushioning and better breathability, suitable for comfort-focused pet bedding and toys. Choosing between the two depends on whether durability or softness is the priority for your pet's needs.

Table of Comparison

| Feature | Cross-Linked Foam | Non-Cross-Linked Foam |

|---|---|---|

| Structure | Closed-cell, dense network | Open-cell, loose structure |

| Durability | High resistance to compression and wear | Lower durability, compresses easily |

| Water Absorption | Low water absorption, waterproof | High water absorption, retains moisture |

| Insulation | Excellent thermal and acoustic insulation | Moderate insulation properties |

| Chemical Resistance | Resistant to chemicals and solvents | Less chemical resistant |

| Applications | Seals, gaskets, sports equipment, insulation | Packaging, cushions, soundproofing |

| Cost | Higher cost due to complex manufacturing | Lower cost, simpler production |

Introduction to Foam Materials

Cross-linked foam features interconnected polymer chains that enhance durability, resilience, and resistance to compression compared to non-cross-linked foam, which has a more open-cell structure resulting in greater softness and breathability. This structural difference impacts applications, with cross-linked foam preferred in high-performance uses such as sports equipment and insulation, while non-cross-linked foam is commonly utilized in packaging and cushioning. Understanding foam materials' molecular architecture is essential for selecting the appropriate type based on mechanical properties and environmental exposure.

What is Cross-linked Foam?

Cross-linked foam is a type of polyurethane foam characterized by its molecules being chemically bonded to form a dense, durable network, which enhances its strength, resilience, and resistance to water and chemicals. This structure results in a closed-cell foam with superior insulation, impact absorption, and long-term stability compared to non-cross-linked foam. Common applications include sports equipment padding, mattresses, and insulation materials due to its enhanced performance properties.

What is Non-cross-linked Foam?

Non-cross-linked foam consists of polyurethane foam with polymer chains that are not chemically bonded, resulting in a softer, more flexible, and less durable material compared to cross-linked foam. This type of foam offers high porosity and breathability, making it ideal for applications like cushioning, upholstery, and bedding where comfort and airflow are crucial. Its open-cell structure allows easier compression and quicker recovery, but it lacks the enhanced mechanical strength and chemical resistance found in cross-linked foam.

Manufacturing Processes: Cross-linked vs Non-cross-linked

Cross-linked foam manufacturing involves exposing polymer beads to high-energy radiation or chemical agents, creating a three-dimensional network that enhances durability, resilience, and water resistance. Non-cross-linked foam is produced through standard polymer foaming methods without additional bonding, resulting in a more flexible but less structurally robust material. The cross-linking process generates foam suitable for demanding applications like insulation and packaging, while non-cross-linked foam fits lighter uses such as cushioning and disposable products.

Physical and Chemical Properties Comparison

Cross-linked foam features a chemically bonded network structure, resulting in higher tensile strength, improved tear resistance, and enhanced dimensional stability compared to non-cross-linked foam. Non-cross-linked foam lacks these chemical bonds, making it more flexible but less durable, with lower resistance to compression set and environmental degradation. The closed-cell nature of cross-linked foam also provides superior water and chemical resistance, whereas non-cross-linked foam tends to be more open-celled and absorbent.

Key Applications for Cross-linked Foam

Cross-linked foam offers superior durability and resilience, making it ideal for high-performance applications such as automotive seating, sports equipment padding, and protective packaging. Its closed-cell structure provides excellent water resistance and thermal insulation, which enhances its use in construction and insulation panels. These properties enable cross-linked foam to outperform non-cross-linked foam in environments demanding long-lasting cushioning and moisture barrier capabilities.

Key Applications for Non-cross-linked Foam

Non-cross-linked foam is widely used in packaging, cushioning, and insulation due to its flexibility and cost-effectiveness. Its open-cell structure allows excellent breathability and water absorption, making it suitable for medical sponges, cleaning pads, and soundproofing materials. The foam's ease of manufacturing and recyclability also benefits applications in automotive interiors and household goods.

Performance Differences in Real-world Use

Cross-linked foam exhibits superior durability, higher tensile strength, and enhanced resistance to water absorption compared to non-cross-linked foam, making it ideal for outdoor and high-stress applications. Non-cross-linked foam offers greater softness and flexibility, often preferred in cushioning and packaging where comfort and impact absorption are prioritized. In real-world use, cross-linked foam maintains structural integrity over time under mechanical stress, while non-cross-linked foam may compress and degrade faster but provides better shock absorption initially.

Cost & Sustainability Considerations

Cross-linked foam generally incurs higher production costs due to its complex manufacturing process and enhanced durability, making it a pricier option compared to non-cross-linked foam. From a sustainability perspective, cross-linked foam offers greater longevity and resistance to degradation, reducing the frequency of replacement and associated waste, which can offset its initial environmental impact. Non-cross-linked foam, while cheaper upfront, tends to degrade faster and may contribute more to landfill waste, raising concerns about long-term sustainability.

Choosing the Right Foam for Your Application

Cross-linked foam offers superior durability, resilience, and resistance to moisture, making it ideal for heavy-duty applications such as packaging, construction, and automotive cushioning. Non-cross-linked foam provides greater softness and compressibility, suited for comfort-focused uses like bedding, upholstery, and soundproofing. Selecting the right foam depends on balancing factors like load-bearing requirements, environmental exposure, and desired comfort level to optimize performance and longevity.

Cross-linked foam vs Non-cross-linked foam Infographic

materialdif.com

materialdif.com