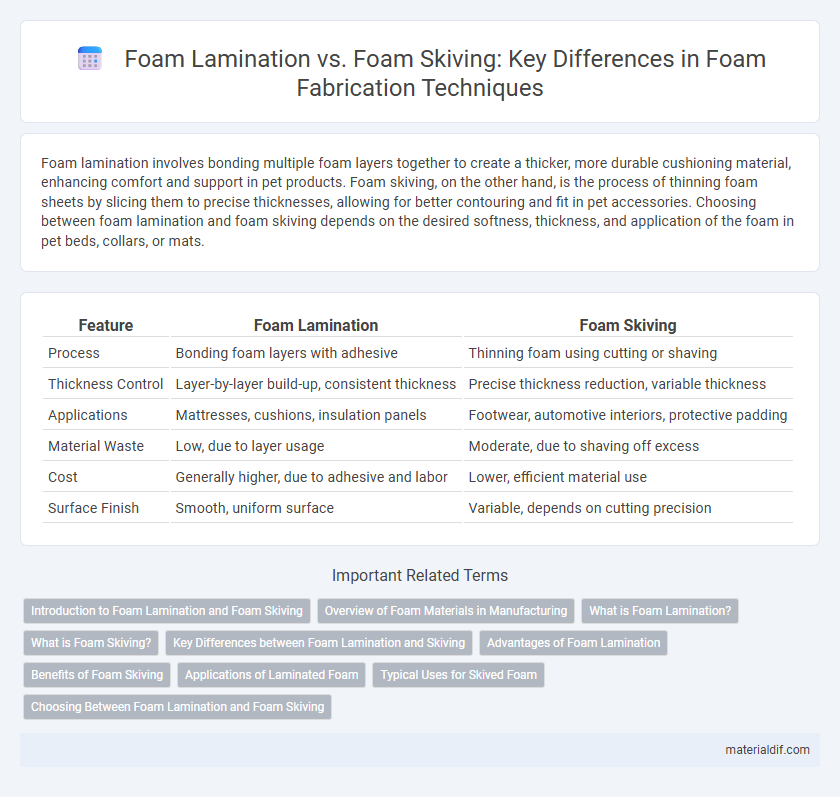

Foam lamination involves bonding multiple foam layers together to create a thicker, more durable cushioning material, enhancing comfort and support in pet products. Foam skiving, on the other hand, is the process of thinning foam sheets by slicing them to precise thicknesses, allowing for better contouring and fit in pet accessories. Choosing between foam lamination and foam skiving depends on the desired softness, thickness, and application of the foam in pet beds, collars, or mats.

Table of Comparison

| Feature | Foam Lamination | Foam Skiving |

|---|---|---|

| Process | Bonding foam layers with adhesive | Thinning foam using cutting or shaving |

| Thickness Control | Layer-by-layer build-up, consistent thickness | Precise thickness reduction, variable thickness |

| Applications | Mattresses, cushions, insulation panels | Footwear, automotive interiors, protective padding |

| Material Waste | Low, due to layer usage | Moderate, due to shaving off excess |

| Cost | Generally higher, due to adhesive and labor | Lower, efficient material use |

| Surface Finish | Smooth, uniform surface | Variable, depends on cutting precision |

Introduction to Foam Lamination and Foam Skiving

Foam lamination involves bonding foam layers to fabric or other materials using adhesives or heat, creating a durable and flexible composite ideal for upholstery, insulation, and packaging. Foam skiving is the process of shaving down foam thickness to achieve precise gauge control and smooth edges, enhancing comfort and fit in applications like footwear insoles and protective padding. Both techniques optimize foam functionality by tailoring thickness and adhesion properties to specific industry requirements.

Overview of Foam Materials in Manufacturing

Foam lamination involves bonding foam layers onto substrates to enhance cushioning, insulation, and durability in products such as footwear, automotive interiors, and packaging. Foam skiving is the precise shaving or thinning of foam sheets to achieve consistent thickness and flexibility, crucial in industries requiring lightweight and ergonomic components. Both processes utilize diverse foam materials like polyurethane, polyethylene, and EVA, selected for their specific mechanical properties and manufacturing requirements.

What is Foam Lamination?

Foam lamination involves bonding thin layers of foam to other materials such as fabric, plastic, or metal using adhesives or heat to create a composite structure with enhanced durability and cushioning. This process improves the foam's performance in applications like upholstery, automotive interiors, and packaging by adding strength and stability without significantly increasing weight. Foam lamination offers precise thickness control and seamless integration compared to foam skiving, which primarily focuses on slicing foam layers to a desired thickness.

What is Foam Skiving?

Foam skiving is a precise technique that involves slicing foam sheets into thinner, uniform layers to achieve specific thickness requirements. This method enhances foam flexibility and reduces bulk without compromising cushioning properties, making it ideal for applications needing lightweight and form-fitting materials. Unlike foam lamination, which bonds multiple foam layers together, foam skiving modifies the foam's thickness by removing material rather than adding layers.

Key Differences between Foam Lamination and Skiving

Foam lamination involves bonding multiple foam layers or foam to other materials using adhesives or heat, creating a thicker, multi-layered composite with enhanced cushioning and structural properties. Foam skiving is the precise slicing or shaving of foam to reduce its thickness or shape it, maintaining a single foam layer's integrity without adding new layers. The key differences lie in lamination combining layers for increased thickness and strength, whereas skiving thins or shapes foam surfaces for custom thickness and flexibility.

Advantages of Foam Lamination

Foam lamination offers superior durability and enhanced structural integrity by bonding foam to various substrates, ensuring consistent thickness and improved surface smoothness. This process enables efficient mass production with reduced material waste compared to foam skiving, which involves slicing thin foam layers and may result in uneven edges and lower strength. Lamination also provides better resistance to moisture and environmental factors, extending the lifespan of foam products in applications like insulation, cushioning, and packaging.

Benefits of Foam Skiving

Foam skiving offers precise thickness control and enhanced edge quality, enabling seamless integration into complex laminates without adding bulk. This process reduces waste by efficiently trimming foam layers, improving material utilization and cost-effectiveness. Superior bonding surface and consistent foam density achieved through skiving contribute to stronger, more durable laminated products ideal for automotive, aerospace, and cushioning applications.

Applications of Laminated Foam

Laminated foam is widely used in applications requiring enhanced cushioning and structural support, such as automotive seating, footwear midsoles, and protective packaging. Its ability to combine multiple foam layers with different densities improves durability and comfort in sports equipment and medical orthotics. Foam lamination also excels in soundproofing panels and insulation materials, where layered construction optimizes acoustic and thermal performance.

Typical Uses for Skived Foam

Skived foam is commonly used in applications requiring thin, flexible foam layers such as gaskets, seals, and medical cushioning due to its smooth surface and precise thickness control. This technique allows for the production of foam sheets with consistent density and minimal waste, ideal for automotive, electronics, and healthcare industries. The precision of skiving ensures compatibility with adhesive bonding and lamination processes, enhancing product durability and performance.

Choosing Between Foam Lamination and Foam Skiving

Choosing between foam lamination and foam skiving depends on the desired product performance and cost-efficiency. Foam lamination provides superior durability and enhanced cushioning by bonding foam with other materials, ideal for upholstery and footwear applications. Foam skiving offers precise thickness control and flexibility, making it suitable for lightweight, contour-sensitive products such as automotive interiors and protective gear.

Foam lamination vs Foam skiving Infographic

materialdif.com

materialdif.com