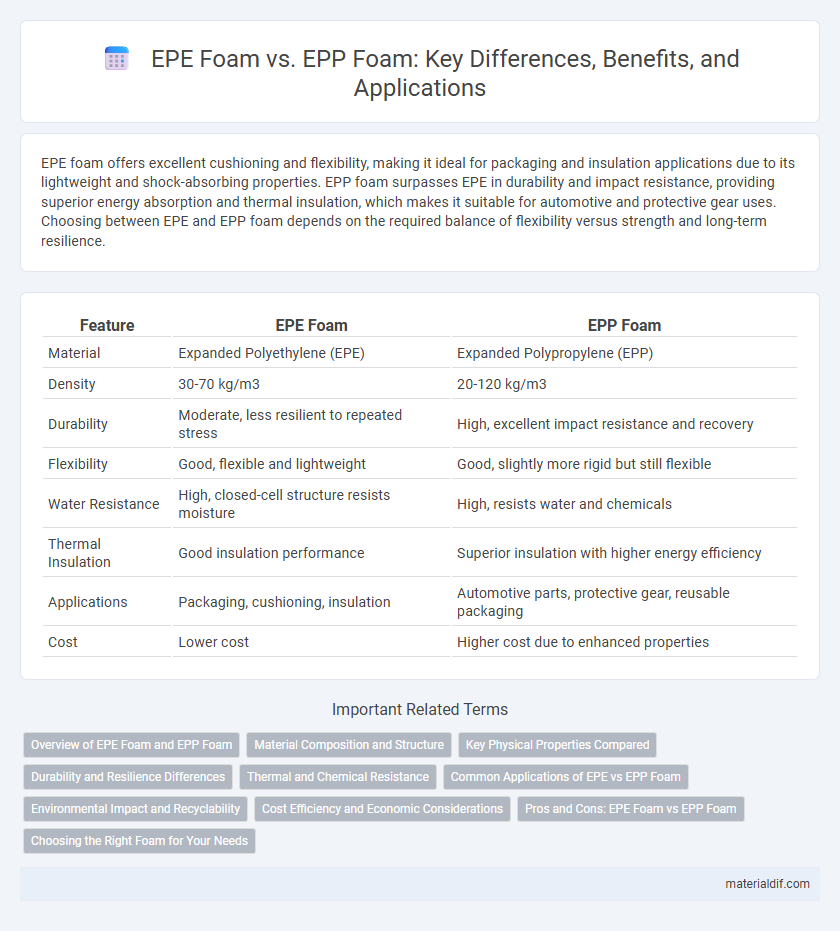

EPE foam offers excellent cushioning and flexibility, making it ideal for packaging and insulation applications due to its lightweight and shock-absorbing properties. EPP foam surpasses EPE in durability and impact resistance, providing superior energy absorption and thermal insulation, which makes it suitable for automotive and protective gear uses. Choosing between EPE and EPP foam depends on the required balance of flexibility versus strength and long-term resilience.

Table of Comparison

| Feature | EPE Foam | EPP Foam |

|---|---|---|

| Material | Expanded Polyethylene (EPE) | Expanded Polypropylene (EPP) |

| Density | 30-70 kg/m3 | 20-120 kg/m3 |

| Durability | Moderate, less resilient to repeated stress | High, excellent impact resistance and recovery |

| Flexibility | Good, flexible and lightweight | Good, slightly more rigid but still flexible |

| Water Resistance | High, closed-cell structure resists moisture | High, resists water and chemicals |

| Thermal Insulation | Good insulation performance | Superior insulation with higher energy efficiency |

| Applications | Packaging, cushioning, insulation | Automotive parts, protective gear, reusable packaging |

| Cost | Lower cost | Higher cost due to enhanced properties |

Overview of EPE Foam and EPP Foam

EPE foam, or Expanded Polyethylene, is characterized by its lightweight, flexible, and cushioning properties, making it suitable for packaging, insulation, and shock absorption. EPP foam, or Expanded Polypropylene, offers higher impact resistance, superior energy absorption, and excellent durability, commonly used in automotive parts, protective gear, and reusable packaging. Both EPE and EPP foams feature closed-cell structures, but EPP's enhanced resilience and thermal stability distinguish it from EPE for demanding applications.

Material Composition and Structure

EPE foam is made from expanded polyethylene beads fused together, resulting in a soft, flexible, and lightweight structure with excellent shock absorption. EPP foam consists of expanded polypropylene beads, creating a highly resilient and durable material with enhanced impact resistance and superior energy absorption. The closed-cell structure of EPP foam offers greater stiffness and thermal insulation compared to the more open, elastic network found in EPE foam.

Key Physical Properties Compared

EPE foam is characterized by its lightweight structure, excellent cushioning, and high flexibility, making it ideal for shock absorption and packaging applications. EPP foam offers superior impact resistance, higher resilience, and excellent thermal insulation, with a cellular structure that allows it to recover its shape after compression. The key physical properties comparison highlights EPE foam's softness and elasticity versus EPP foam's durability, energy absorption capability, and greater resistance to deformation under stress.

Durability and Resilience Differences

EPE foam offers excellent flexibility and cushioning but tends to compress and wear out faster under repeated impact compared to EPP foam. EPP foam exhibits superior durability and resilience due to its closed-cell structure, allowing it to maintain shape and absorb shock over prolonged use. The enhanced strength of EPP foam makes it ideal for applications requiring repeated stress resistance and long-term performance.

Thermal and Chemical Resistance

EPE foam offers moderate thermal resistance, withstanding temperatures up to approximately 80degC, making it suitable for applications requiring lightweight cushioning but limited heat exposure. EPP foam exhibits superior thermal resistance, enduring temperatures up to 120degC, which enhances its performance in high-temperature environments and thermal insulation applications. Chemically, EPP foam demonstrates higher resistance to oils, solvents, and most acids compared to EPE foam, which has lower chemical durability and may degrade faster upon exposure to harsh substances.

Common Applications of EPE vs EPP Foam

EPE foam is widely used for packaging fragile goods, insulation, and cushioning due to its lightweight and shock-absorbing properties. EPP foam, known for its superior durability and energy absorption, is commonly applied in automotive components, protective helmets, and reusable packaging solutions. Both foams serve distinct purposes with EPE favoring disposable protection and EPP excelling in impact-resistant, long-term applications.

Environmental Impact and Recyclability

EPE foam, made from expanded polyethylene, is lightweight and offers good cushioning but is less eco-friendly due to limited recyclability and longer degradation times in landfills. EPP foam, or expanded polypropylene, stands out for its excellent recyclability and lower environmental impact, as it can be reused multiple times without significant quality loss. EPP foam's durability and thermal resistance make it a sustainable choice for industries aiming to reduce plastic waste and promote circular economy practices.

Cost Efficiency and Economic Considerations

EPE foam offers a cost-effective solution with lower production expenses, making it ideal for large-scale packaging applications where budget constraints are significant. EPP foam, while more expensive upfront, provides superior durability and reusability, reducing long-term replacement costs and improving overall economic value. Choosing between EPE and EPP foam depends on balancing initial investment against lifecycle cost efficiency tailored to specific operational needs.

Pros and Cons: EPE Foam vs EPP Foam

EPE foam offers excellent cushioning and cost-effectiveness, making it ideal for packaging and insulation, but it lacks the durability and impact resistance found in EPP foam. EPP foam boasts superior resilience, lightweight properties, and eco-friendliness, suited for automotive parts and protective gear, yet it comes at a higher price point compared to EPE foam. Choosing between EPE and EPP foam depends on whether priority is on budget and basic protection or enhanced durability and repeated impact absorption.

Choosing the Right Foam for Your Needs

EPE foam offers excellent cushioning and shock absorption, making it ideal for packaging fragile items and insulation. EPP foam boasts superior durability, flexibility, and energy absorption, often used in automotive parts, helmets, and reusable packaging. Selecting the right foam depends on whether your priority is lightweight protection with moderate durability (EPE) or enhanced resilience and impact resistance (EPP).

EPE Foam vs EPP Foam Infographic

materialdif.com

materialdif.com