HDPE foam offers superior rigidity and higher temperature resistance compared to LDPE foam, making it ideal for applications requiring structural strength and durability. LDPE foam provides excellent flexibility and shock absorption, which is beneficial for cushioning, packaging, and insulation purposes. Both materials are lightweight and resistant to moisture, but HDPE foam is better suited for heavy-duty uses while LDPE foam excels in impact protection and versatility.

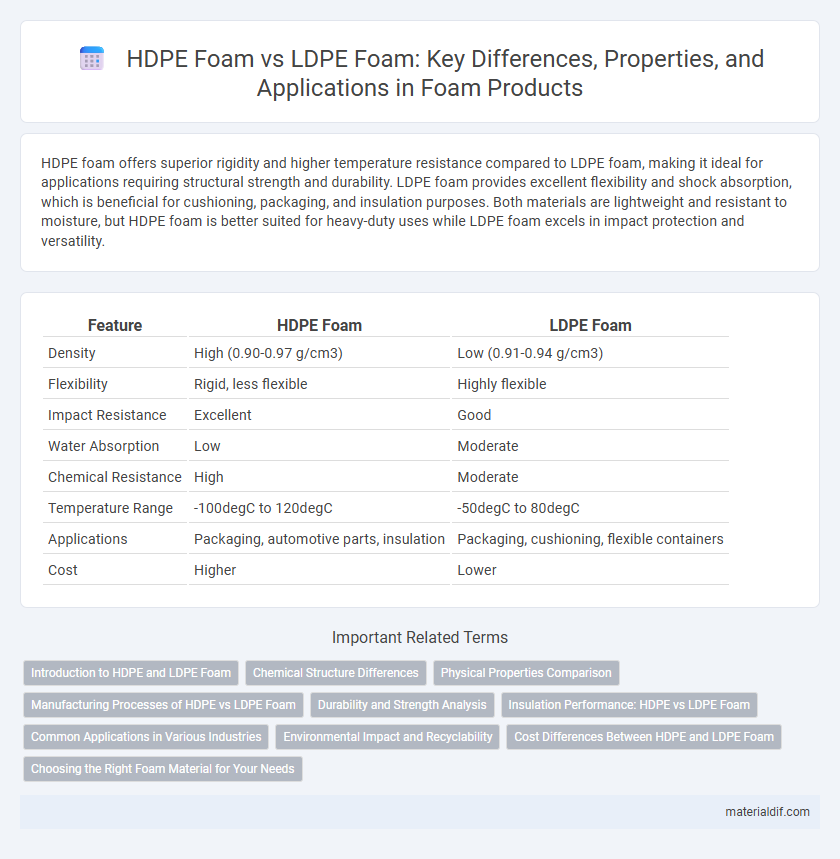

Table of Comparison

| Feature | HDPE Foam | LDPE Foam |

|---|---|---|

| Density | High (0.90-0.97 g/cm3) | Low (0.91-0.94 g/cm3) |

| Flexibility | Rigid, less flexible | Highly flexible |

| Impact Resistance | Excellent | Good |

| Water Absorption | Low | Moderate |

| Chemical Resistance | High | Moderate |

| Temperature Range | -100degC to 120degC | -50degC to 80degC |

| Applications | Packaging, automotive parts, insulation | Packaging, cushioning, flexible containers |

| Cost | Higher | Lower |

Introduction to HDPE and LDPE Foam

HDPE foam, made from high-density polyethylene, offers superior strength, rigidity, and chemical resistance compared to LDPE foam, which is derived from low-density polyethylene and provides greater flexibility and cushioning properties. HDPE foam is favored in applications requiring durability and structural support, such as automotive components and industrial packaging, while LDPE foam is commonly used for softer packaging, insulation, and shock absorption. Both foams exhibit excellent moisture resistance and thermal insulation but differ significantly in density, compressive strength, and deformation characteristics.

Chemical Structure Differences

HDPE foam features a linear polymer chain with minimal branching, resulting in a denser, more crystalline structure that enhances rigidity and chemical resistance. LDPE foam, characterized by significant long and short chain branching within its polymer matrix, exhibits lower crystallinity, leading to greater flexibility and impact absorption. These chemical structure differences directly influence the foam's mechanical properties, thermal stability, and suitability for various industrial applications.

Physical Properties Comparison

HDPE foam possesses higher density and superior tensile strength compared to LDPE foam, resulting in enhanced rigidity and impact resistance. LDPE foam offers greater flexibility and better cushioning properties due to its lower density and softer texture. Both materials exhibit different thermal conductivity rates, with HDPE foam providing improved insulation capabilities over LDPE foam.

Manufacturing Processes of HDPE vs LDPE Foam

HDPE foam is primarily manufactured using high-pressure gas injection or chemical blowing agents to create a rigid and dense cellular structure, ensuring greater stiffness and impact resistance. LDPE foam production often involves melt-blowing or extrusion processes with lower processing temperatures, resulting in a softer, more flexible foam with fine cell structures. The manufacturing process differences stem from the distinct polymer properties, where HDPE's higher crystallinity demands more controlled expansion, while LDPE's branched chains allow easier foaming and flexible end-use applications.

Durability and Strength Analysis

HDPE foam exhibits superior durability and strength compared to LDPE foam due to its higher density and crystallinity, making it ideal for heavy-duty applications requiring impact resistance and long-term performance. LDPE foam, while more flexible and lightweight, provides less structural integrity and is more prone to deformation under stress. The enhanced tensile strength and abrasion resistance of HDPE foam contribute to its widespread use in industrial and construction environments where material longevity is critical.

Insulation Performance: HDPE vs LDPE Foam

HDPE foam offers superior insulation performance compared to LDPE foam due to its higher density and closed-cell structure, which significantly reduces thermal conductivity. LDPE foam, while more flexible and lightweight, has a more open-cell composition that allows greater heat transfer, making it less effective for thermal insulation applications. For projects requiring enhanced thermal resistance, HDPE foam provides better energy efficiency and durability.

Common Applications in Various Industries

HDPE foam is extensively used in automotive parts, construction insulation, and packaging due to its high strength and rigidity, while LDPE foam finds common applications in cushioning, flexible packaging, and protective padding in consumer electronics and medical industries. The chemical resistance and durability of HDPE foam make it ideal for heavy-duty industrial uses, whereas the softness and flexibility of LDPE foam cater to delicate product protection and thermal insulation needs. Both foams serve critical roles across sectors such as automotive, healthcare, packaging, and construction, tailored to specific performance and handling requirements.

Environmental Impact and Recyclability

HDPE foam, derived from high-density polyethylene, exhibits greater environmental sustainability due to its higher strength-to-weight ratio and superior recyclability compared to LDPE foam. LDPE foam, made from low-density polyethylene, has a lower melting point and tends to degrade faster, but it is less efficient for recycling processes, often leading to increased landfill accumulation. Both foams are recyclable; however, HDPE foam's chemical structure allows for more effective reuse and a reduced carbon footprint during recycling stages.

Cost Differences Between HDPE and LDPE Foam

HDPE foam generally costs more than LDPE foam due to its higher density and superior mechanical properties, which enhance durability and load-bearing capacity. LDPE foam is more budget-friendly, offering adequate cushioning and flexibility for applications where cost efficiency is a priority. The price difference is influenced by raw material costs, processing conditions, and the intended application requirements.

Choosing the Right Foam Material for Your Needs

HDPE foam offers higher density, superior rigidity, and excellent chemical resistance, making it ideal for structural applications requiring durability. LDPE foam provides greater flexibility, softer texture, and enhanced cushioning, suitable for packaging and impact absorption needs. Selecting between HDPE and LDPE foam depends on prioritizing strength and resistance versus flexibility and softness for your specific project requirements.

HDPE foam vs LDPE foam Infographic

materialdif.com

materialdif.com