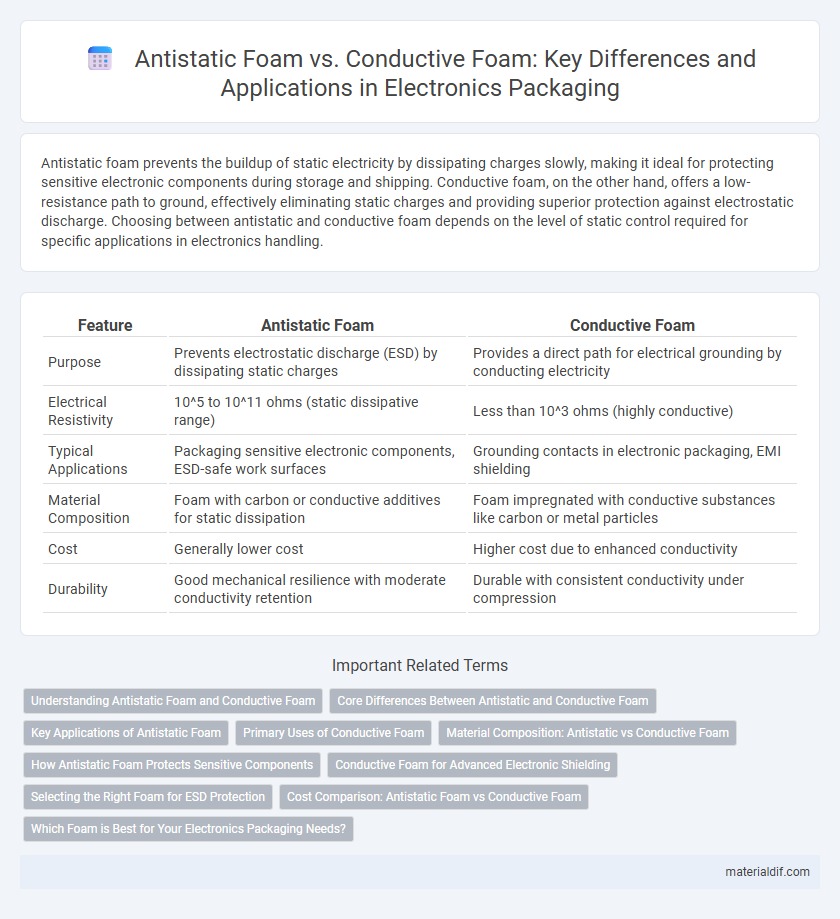

Antistatic foam prevents the buildup of static electricity by dissipating charges slowly, making it ideal for protecting sensitive electronic components during storage and shipping. Conductive foam, on the other hand, offers a low-resistance path to ground, effectively eliminating static charges and providing superior protection against electrostatic discharge. Choosing between antistatic and conductive foam depends on the level of static control required for specific applications in electronics handling.

Table of Comparison

| Feature | Antistatic Foam | Conductive Foam |

|---|---|---|

| Purpose | Prevents electrostatic discharge (ESD) by dissipating static charges | Provides a direct path for electrical grounding by conducting electricity |

| Electrical Resistivity | 10^5 to 10^11 ohms (static dissipative range) | Less than 10^3 ohms (highly conductive) |

| Typical Applications | Packaging sensitive electronic components, ESD-safe work surfaces | Grounding contacts in electronic packaging, EMI shielding |

| Material Composition | Foam with carbon or conductive additives for static dissipation | Foam impregnated with conductive substances like carbon or metal particles |

| Cost | Generally lower cost | Higher cost due to enhanced conductivity |

| Durability | Good mechanical resilience with moderate conductivity retention | Durable with consistent conductivity under compression |

Understanding Antistatic Foam and Conductive Foam

Antistatic foam is designed to prevent the buildup of static electricity by dissipating charges slowly, making it ideal for protecting sensitive electronic components during storage and transport. Conductive foam contains carbon or metal particles that create a continuous conductive path, effectively grounding and shielding devices from electrostatic discharge. Understanding the differences in electrical properties and applications of antistatic versus conductive foam is crucial to selecting the right material for electronic packaging and protection.

Core Differences Between Antistatic and Conductive Foam

Antistatic foam prevents static electricity buildup by dissipating static charges while maintaining electrical resistance, ideal for protecting sensitive electronic components from electrostatic discharge. Conductive foam, in contrast, offers low electrical resistance and effectively creates a shielding path for static charges to ground, ensuring superior electrostatic protection during storage and transportation. The core difference lies in electrical conductivity levels: antistatic foam reduces charge accumulation, whereas conductive foam actively channels charges away.

Key Applications of Antistatic Foam

Antistatic foam is essential in protecting electronic components by preventing electrostatic discharge in sensitive environments such as semiconductor manufacturing, electronics packaging, and assembly lines. This foam is commonly used in shipping containers, tool storage, and cleanrooms to maintain electrostatic control and ensure component integrity. Its moderate conductivity and static dissipative properties make it ideal for applications requiring controlled discharge without complete grounding.

Primary Uses of Conductive Foam

Conductive foam is primarily used for protecting sensitive electronic components from electrostatic discharge (ESD) during storage and transportation, ensuring the safe handling of integrated circuits and semiconductors. Its unique composition allows it to dissipate static charges effectively, making it ideal for ESD-safe packaging and shielding applications. Conductive foam's role is crucial in industries such as electronics manufacturing, aerospace, and telecommunications where static damage can lead to device failure.

Material Composition: Antistatic vs Conductive Foam

Antistatic foam is typically composed of polyurethane infused with antistatic agents that dissipate static charges without providing full conductivity, making it ideal for preventing electrostatic discharge in sensitive electronic packaging. Conductive foam, on the other hand, incorporates carbon or metal particles within the foam matrix, creating a continuous path for electrical conductivity and offering enhanced protection against electrostatic buildup. The material composition difference directly impacts their suitability, with antistatic foam reducing static buildup and conductive foam enabling effective grounding in electronic component protection.

How Antistatic Foam Protects Sensitive Components

Antistatic foam protects sensitive electronic components by dissipating static electricity that can cause damage during handling and transport. Its low electrical resistance prevents the buildup of static charges, ensuring that delicate semiconductor devices remain safe from electrostatic discharge (ESD). This foam is essential in packaging for integrated circuits, printed circuit boards, and other components prone to ESD damage.

Conductive Foam for Advanced Electronic Shielding

Conductive foam offers superior electromagnetic interference (EMI) shielding for advanced electronic components by providing a consistent low-resistance path to ground, essential for sensitive devices. Its structure allows efficient dissipation of static charges and absorption of high-frequency noise, making it ideal for protecting circuit boards and connectors in high-performance electronics. Compared to antistatic foam, conductive foam delivers enhanced conductivity, ensuring robust protection against electrostatic discharge (ESD) and electromagnetic compatibility (EMC) challenges.

Selecting the Right Foam for ESD Protection

Antistatic foam offers moderate resistance to static electricity by dissipating charges slowly, making it suitable for low-risk ESD environments. Conductive foam provides low electrical resistance, allowing rapid discharge of static electricity, ideal for high-sensitivity electronic components requiring stringent ESD protection. Selecting the right foam depends on the specific ESD tolerance of the devices and the desired rate of static charge dissipation during handling and storage.

Cost Comparison: Antistatic Foam vs Conductive Foam

Antistatic foam generally costs less than conductive foam due to its lower material complexity and production processes. Conductive foam incorporates more specialized conductive fillers such as carbon or metal particles that increase manufacturing expenses. When considering large-scale applications, the cost difference becomes significant, making antistatic foam a budget-friendly choice for moderate static protection.

Which Foam is Best for Your Electronics Packaging Needs?

Antistatic foam is designed to prevent the buildup of static electricity, making it ideal for protecting sensitive electronic components from electrostatic discharge during handling and transport. Conductive foam, on the other hand, not only dissipates static charges but also provides a conductive path to ground, offering enhanced protection for high-sensitivity devices prone to static damage. Choosing between antistatic and conductive foam depends on the specific electronic components' sensitivity and the environment in which they will be stored or shipped, with conductive foam generally preferred for critical applications requiring maximum static protection.

Antistatic foam vs Conductive foam Infographic

materialdif.com

materialdif.com