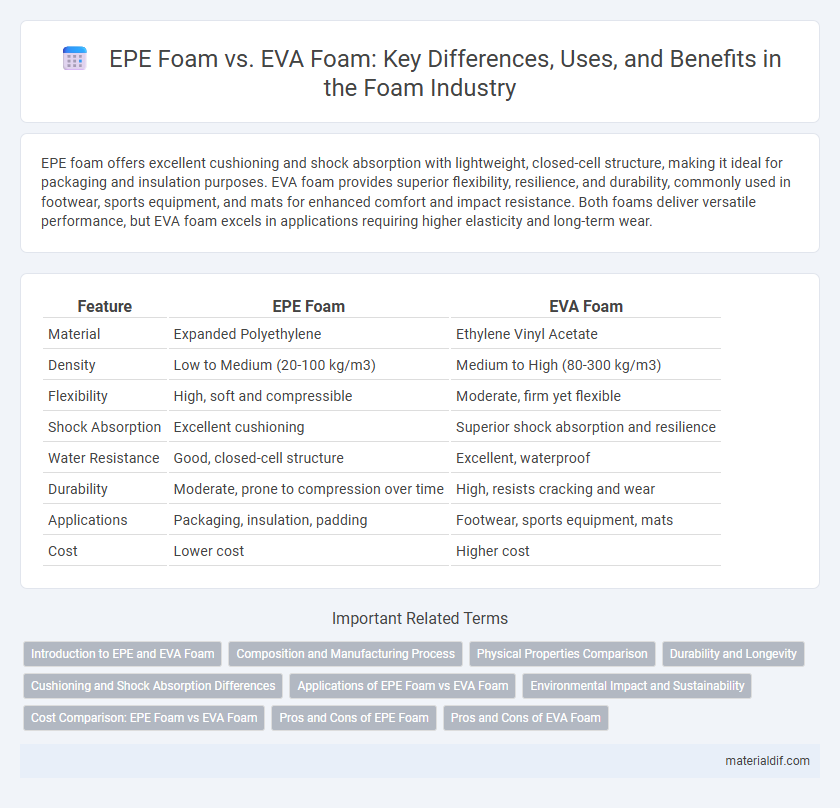

EPE foam offers excellent cushioning and shock absorption with lightweight, closed-cell structure, making it ideal for packaging and insulation purposes. EVA foam provides superior flexibility, resilience, and durability, commonly used in footwear, sports equipment, and mats for enhanced comfort and impact resistance. Both foams deliver versatile performance, but EVA foam excels in applications requiring higher elasticity and long-term wear.

Table of Comparison

| Feature | EPE Foam | EVA Foam |

|---|---|---|

| Material | Expanded Polyethylene | Ethylene Vinyl Acetate |

| Density | Low to Medium (20-100 kg/m3) | Medium to High (80-300 kg/m3) |

| Flexibility | High, soft and compressible | Moderate, firm yet flexible |

| Shock Absorption | Excellent cushioning | Superior shock absorption and resilience |

| Water Resistance | Good, closed-cell structure | Excellent, waterproof |

| Durability | Moderate, prone to compression over time | High, resists cracking and wear |

| Applications | Packaging, insulation, padding | Footwear, sports equipment, mats |

| Cost | Lower cost | Higher cost |

Introduction to EPE and EVA Foam

EPE foam, or Expanded Polyethylene foam, is a lightweight, flexible material known for its excellent shock absorption and thermal insulation properties, commonly used in packaging and cushioning applications. EVA foam, or Ethylene Vinyl Acetate foam, offers superior elasticity, durability, and resistance to UV radiation and stress, making it ideal for sports equipment, footwear, and craft projects. Both EPE and EVA foams provide cushioning solutions, but EPE is favored for impact protection in packaging, while EVA excels in comfort and resilience for wearable and recreational products.

Composition and Manufacturing Process

EPE foam is composed of expanded polyethylene beads fused through a steam-chest molding process, resulting in a lightweight material with excellent cushioning and impact absorption properties. EVA foam, made from ethylene vinyl acetate copolymer, undergoes a closed-cell foam extrusion or molding process that creates a flexible, durable, and resilient material with superior shock absorption and elasticity. The manufacturing differences influence their applications, with EPE focusing on cost-effective packaging and cushioning, while EVA offers enhanced performance for sports equipment and footwear.

Physical Properties Comparison

EPE foam exhibits excellent resilience and lightweight characteristics with a density ranging from 18 to 35 kg/m3, making it ideal for shock absorption and cushioning in packaging applications. EVA foam offers superior flexibility, higher tensile strength, and better resistance to UV radiation and chemicals, with densities typically between 70 and 120 kg/m3, making it suitable for sports equipment and footwear. Both foams differ significantly in compression set values, where EVA foam maintains shape under stress better than EPE foam, enhancing durability in high-impact environments.

Durability and Longevity

EPE foam offers exceptional durability due to its resilient closed-cell structure, making it highly resistant to impact, moisture, and abrasion over time. EVA foam provides excellent longevity with superior flexibility and resistance to cracking, maintaining its cushioning properties under continuous stress. Both materials demonstrate strong durability, but EVA foam typically outperforms EPE in sustained flexibility and wear resistance for long-term applications.

Cushioning and Shock Absorption Differences

EPE foam offers superior cushioning due to its lightweight, resilient closed-cell structure that provides excellent shock absorption and durability in various applications. EVA foam, with its flexible and softer composition, delivers enhanced shock absorption and comfort, making it ideal for footwear and protective gear. The choice between EPE and EVA foam depends on the specific cushioning needs, as EVA provides better energy return while EPE excels in maintaining shape under repetitive impact.

Applications of EPE Foam vs EVA Foam

EPE foam is widely used in packaging, insulation, and cushioning applications due to its excellent shock absorption and lightweight properties. EVA foam is favored in sports equipment, footwear, and automotive interiors for its superior flexibility, durability, and resistance to UV radiation. Choosing between EPE and EVA foam depends on specific application requirements such as impact resilience for packaging or comfort and longevity in wearable products.

Environmental Impact and Sustainability

EPE foam, made from expanded polyethylene, is lightweight and recyclable but often lacks biodegradability, contributing to long-term environmental waste. EVA foam, composed of ethylene-vinyl acetate, is more durable and flexible, but its production involves petrochemicals and generates higher carbon emissions. Both foams pose challenges for sustainability, with ongoing research aimed at improving recycling methods and developing bio-based alternatives.

Cost Comparison: EPE Foam vs EVA Foam

EPE foam typically costs less than EVA foam due to its simpler manufacturing process and lower raw material expenses, making it a more budget-friendly option for applications requiring lightweight cushioning. EVA foam offers higher durability and resilience but comes at a higher price point, reflecting its superior material properties and longer lifespan. When choosing between EPE and EVA foam, consider the balance between initial cost and performance requirements to determine the most cost-effective solution.

Pros and Cons of EPE Foam

EPE foam offers excellent cushioning, lightweight durability, and resistance to moisture, making it ideal for packaging and protective applications. However, it has lower elasticity compared to EVA foam, which limits its flexibility and impact absorption in high-performance uses. Its relatively lower thermal insulation and compression recovery also differentiate it from EVA foam's enhanced comfort and resilience.

Pros and Cons of EVA Foam

EVA foam offers superior durability, flexibility, and resistance to UV rays and chemicals compared to EPE foam, making it ideal for applications needing long-lasting cushioning and shock absorption. However, EVA foam is typically more expensive and heavier than EPE foam, which may impact cost-efficiency and portability in some uses. Its closed-cell structure provides excellent water resistance but limits breathability, potentially causing discomfort in prolonged contact scenarios.

EPE foam vs EVA foam Infographic

materialdif.com

materialdif.com