Anti-static foam prevents static electricity buildup by dissipating static charges on its surface, making it ideal for protecting sensitive electronic components. Conductive foam, on the other hand, contains conductive particles that create a path for static charges to ground, offering a higher level of protection against electrostatic discharge (ESD). Choosing between anti-static and conductive foam depends on the level of ESD protection required and the specific application needs.

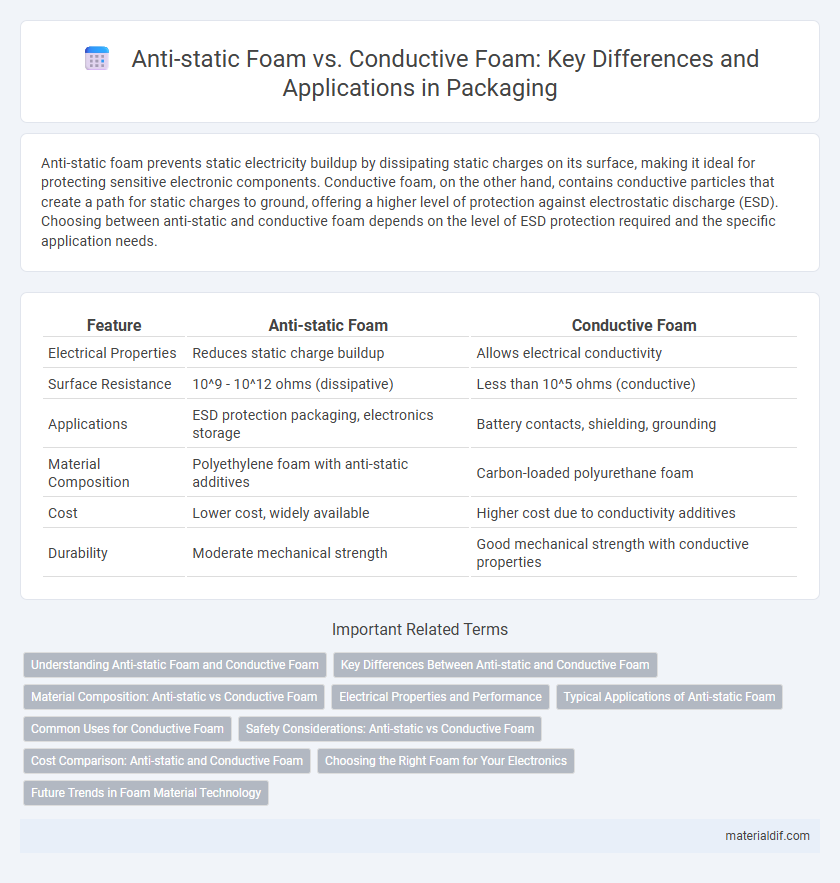

Table of Comparison

| Feature | Anti-static Foam | Conductive Foam |

|---|---|---|

| Electrical Properties | Reduces static charge buildup | Allows electrical conductivity |

| Surface Resistance | 10^9 - 10^12 ohms (dissipative) | Less than 10^5 ohms (conductive) |

| Applications | ESD protection packaging, electronics storage | Battery contacts, shielding, grounding |

| Material Composition | Polyethylene foam with anti-static additives | Carbon-loaded polyurethane foam |

| Cost | Lower cost, widely available | Higher cost due to conductivity additives |

| Durability | Moderate mechanical strength | Good mechanical strength with conductive properties |

Understanding Anti-static Foam and Conductive Foam

Anti-static foam reduces static electricity buildup by dissipating static charges, making it essential for protecting sensitive electronic components during storage and transit. Conductive foam contains carbon or metal particles that provide a continuous electrical path, effectively grounding static charges to prevent electrostatic discharge. Both types of foam serve critical roles in electronics packaging, with anti-static foam primarily preventing charge accumulation and conductive foam actively grounding static buildup.

Key Differences Between Anti-static and Conductive Foam

Anti-static foam primarily prevents the buildup of static electricity by dissipating electrostatic discharge (ESD) without conducting electricity, making it suitable for protecting sensitive electronic components from static damage. Conductive foam, on the other hand, offers a higher level of electrical conductivity, providing a direct path to ground to neutralize static charges effectively, which is essential for applications requiring grounding of components. Key differences include resistance levels, with anti-static foam having higher resistivity (10^9 to 10^12 ohms) compared to conductive foam's lower resistivity (10^4 to 10^6 ohms), impacting their protective mechanisms and use cases in electronic packaging.

Material Composition: Anti-static vs Conductive Foam

Anti-static foam is typically composed of polyethylene or polyurethane infused with carbon or other conductive additives to dissipate static electricity without providing full conductivity. Conductive foam, in contrast, contains higher concentrations of conductive materials such as carbon black or metal fibers, allowing it to conduct electricity and provide effective shielding against electromagnetic interference. The key difference in material composition lies in the balance of conductive fillers, which determines whether the foam resists or conducts static charges.

Electrical Properties and Performance

Anti-static foam provides surface resistivity in the range of 10^9 to 10^11 ohms per square, effectively preventing static charge buildup without conducting electricity, making it ideal for protecting sensitive electronics from electrostatic discharge (ESD). Conductive foam offers much lower resistivity, typically around 10^2 to 10^4 ohms per square, allowing it to dissipate static charges rapidly by providing a direct electrical path to ground. The choice between anti-static and conductive foam depends on the required level of electrical conductivity and the specific protection needs of electronic components during storage and transport.

Typical Applications of Anti-static Foam

Anti-static foam is commonly used in packaging sensitive electronic components, such as microchips, circuit boards, and semiconductors, to prevent electrostatic discharge (ESD) damage during handling and transport. Unlike conductive foam, which provides a direct path to ground, anti-static foam dissipates static charges slowly to protect devices without attracting dust or contaminants. Typical applications include use in cleanroom environments, electronic assembly lines, and storage containers for delicate electronic parts.

Common Uses for Conductive Foam

Conductive foam is primarily used in the electronics industry for the safe packaging and transportation of sensitive integrated circuits (ICs) and semiconductor devices, protecting them from electrostatic discharge (ESD) damage. It offers excellent dissipation of electrical charge, making it ideal for shielding delicate components during storage and shipping. Common applications include preventing static buildup in PCBs, connectors, and other static-sensitive devices.

Safety Considerations: Anti-static vs Conductive Foam

Anti-static foam prevents the buildup of static electricity without conducting current, making it ideal for protecting sensitive electronic components from electrostatic discharge (ESD) while ensuring user safety. Conductive foam provides a low-resistance path to ground, effectively dissipating static charges but must be handled carefully to avoid unintended short circuits or shocks. Selecting between anti-static and conductive foam depends on specific safety requirements, including the sensitivity of electronics and the risk of electrical hazards during handling and storage.

Cost Comparison: Anti-static and Conductive Foam

Anti-static foam generally costs less than conductive foam due to its simpler chemical composition and manufacturing process. Conductive foam incorporates higher levels of conductive materials like carbon or metal fibers, driving up production expenses and retail prices. Selecting between anti-static and conductive foam depends on balancing necessary electrostatic discharge protection with budget constraints.

Choosing the Right Foam for Your Electronics

Anti-static foam prevents static electricity buildup by dissipating charges, making it ideal for protecting sensitive electronic components during storage and transport. Conductive foam, with its high electrical conductivity, provides a more robust grounding solution for electronic parts requiring direct charge discharge. Selecting the right foam depends on the device's sensitivity level and the specific electrostatic discharge (ESD) protection needed to ensure optimal safety.

Future Trends in Foam Material Technology

Future trends in foam material technology emphasize enhanced electrical properties to meet evolving industry demands. Anti-static foam continues to improve in dissipating static electricity without compromising cushioning, while conductive foam advances by integrating nanomaterials such as carbon nanotubes and graphene to achieve superior conductivity and durability. Innovations also target eco-friendly production methods and multifunctional foams that combine static control with thermal management and antimicrobial features.

Anti-static Foam vs Conductive Foam Infographic

materialdif.com

materialdif.com