Urethane foam offers excellent cushioning and flexibility, making it ideal for pet beds and toys that require softness and durability. Neoprene foam stands out for its superior water resistance and insulation properties, making it suitable for outdoor pet accessories and swimwear. Choosing between urethane and neoprene foam depends on the specific needs of pets, whether prioritizing comfort or protection from moisture and temperature changes.

Table of Comparison

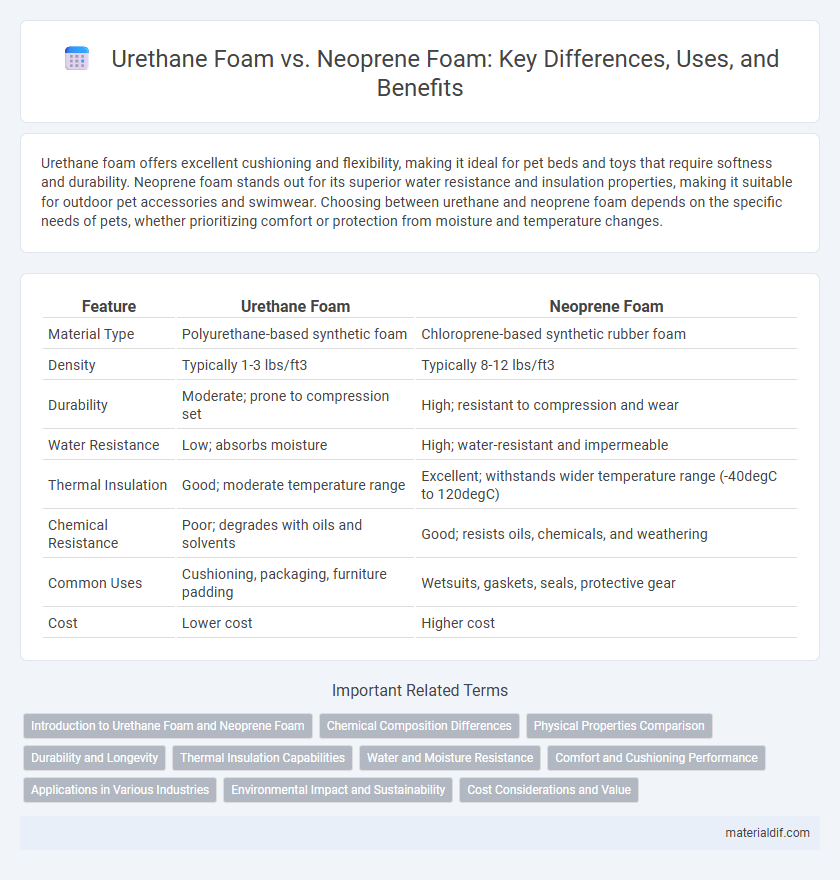

| Feature | Urethane Foam | Neoprene Foam |

|---|---|---|

| Material Type | Polyurethane-based synthetic foam | Chloroprene-based synthetic rubber foam |

| Density | Typically 1-3 lbs/ft3 | Typically 8-12 lbs/ft3 |

| Durability | Moderate; prone to compression set | High; resistant to compression and wear |

| Water Resistance | Low; absorbs moisture | High; water-resistant and impermeable |

| Thermal Insulation | Good; moderate temperature range | Excellent; withstands wider temperature range (-40degC to 120degC) |

| Chemical Resistance | Poor; degrades with oils and solvents | Good; resists oils, chemicals, and weathering |

| Common Uses | Cushioning, packaging, furniture padding | Wetsuits, gaskets, seals, protective gear |

| Cost | Lower cost | Higher cost |

Introduction to Urethane Foam and Neoprene Foam

Urethane foam, widely used in cushioning and insulation, is valued for its flexibility, durability, and excellent load-bearing capabilities, making it ideal for furniture and automotive applications. Neoprene foam, a synthetic rubber material, offers superior resistance to weathering, chemicals, and water, frequently utilized in wetsuits, gaskets, and protective gear. Both foams provide unique properties: urethane excels in comfort and shock absorption, while neoprene is preferred for environmental resilience and sealing effectiveness.

Chemical Composition Differences

Urethane foam is primarily made from polyurethane polymers derived from the reaction of polyols and isocyanates, offering versatility in density and firmness. Neoprene foam, composed of polychloroprene synthetic rubber, contains chlorine atoms providing enhanced chemical resistance and durability. The distinct molecular structures result in different performance characteristics, with urethane foam favoring cushioning applications and neoprene foam excelling in insulation and sealing.

Physical Properties Comparison

Urethane foam offers excellent flexibility and resilience with a typical density ranging from 1.2 to 2.0 lb/ft3, making it lightweight and highly compressible. Neoprene foam exhibits superior chemical resistance and durability, with a higher density around 2.5 to 4.0 lb/ft3, providing better resistance to moisture, oils, and UV exposure. The tensile strength of neoprene foam generally surpasses that of urethane foam, enhancing its suitability for outdoor and industrial applications.

Durability and Longevity

Urethane foam offers excellent durability with high resistance to compression and wear, making it ideal for applications requiring long-term cushioning. Neoprene foam provides superior longevity due to its strong resistance to environmental factors such as ozone, UV rays, and water, which prevents degradation over time. Both foams deliver robust performance, but neoprene's chemical stability and resilience extend its functional lifespan more effectively in harsh conditions.

Thermal Insulation Capabilities

Urethane foam offers superior thermal insulation due to its closed-cell structure, which minimizes heat transfer and enhances energy efficiency in applications such as refrigeration and HVAC systems. Neoprene foam provides moderate thermal insulation along with flexibility and resistance to oil, chemicals, and weathering, making it suitable for industrial gasketing and protective gear. Selecting between urethane and neoprene foam depends on prioritizing either maximum thermal insulation or combined thermal and environmental resilience.

Water and Moisture Resistance

Urethane foam exhibits moderate water resistance but tends to absorb moisture over time, making it less ideal for prolonged exposure to wet environments. Neoprene foam offers superior water and moisture resistance due to its closed-cell structure, preventing water absorption and maintaining durability in damp or aquatic conditions. This makes neoprene foam the preferred choice for applications requiring consistent performance in water-rich settings.

Comfort and Cushioning Performance

Urethane foam offers superior softness and flexibility, providing enhanced comfort and effective cushioning for prolonged use. Neoprene foam exhibits excellent resilience and durability, maintaining consistent cushioning performance under repeated compression and impact. The choice between urethane and neoprene foam depends on specific comfort needs, with urethane excelling in plushness and neoprene in long-term support and shock absorption.

Applications in Various Industries

Urethane foam is widely used in automotive seating, furniture cushioning, and packaging due to its excellent cushioning properties and durability, while neoprene foam is preferred in the medical, sports, and marine industries for its superior resistance to water, oil, and weather conditions. The versatility of urethane foam makes it ideal for insulation and soundproofing applications in construction, whereas neoprene's chemical stability ensures reliability in wetsuits, orthopedic braces, and protective gear. Both foams serve critical roles in industrial applications, yet their unique physical and chemical properties determine their specific usage across diverse sectors.

Environmental Impact and Sustainability

Urethane foam, derived from petroleum-based chemicals, typically exhibits lower recyclability and generates more toxic emissions during production compared to neoprene foam, which can be formulated with chloroprene or limestone-based alternatives that reduce environmental toxicity. Neoprene foam offers better durability and longer lifespan, decreasing the frequency of replacement and waste accumulation, thus enhancing overall sustainability. Both foams present challenges for biodegradability, but advancements in bio-based urethane and recycled neoprene materials are driving improvements in eco-friendly foam applications.

Cost Considerations and Value

Urethane foam typically offers lower upfront costs compared to neoprene foam, making it a budget-friendly option for applications requiring cushioning and insulation. Neoprene foam, while more expensive, provides superior durability, chemical resistance, and longevity, delivering better long-term value in harsh environments. Evaluating project requirements and expected lifespan is crucial to balancing initial investment against performance benefits.

Urethane foam vs Neoprene foam Infographic

materialdif.com

materialdif.com