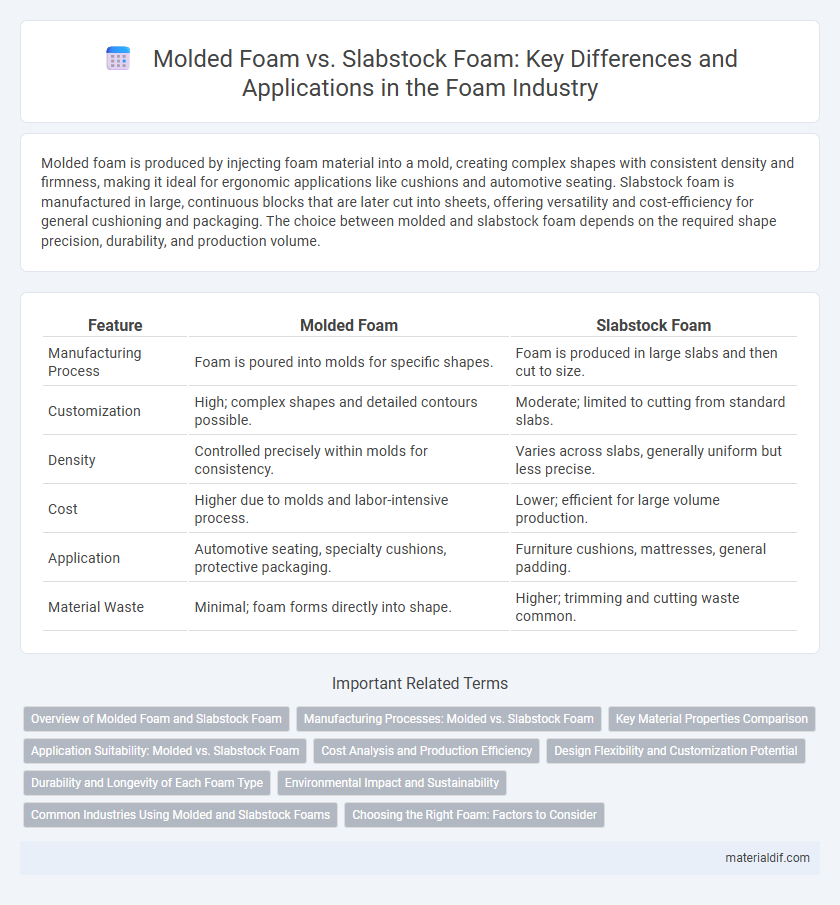

Molded foam is produced by injecting foam material into a mold, creating complex shapes with consistent density and firmness, making it ideal for ergonomic applications like cushions and automotive seating. Slabstock foam is manufactured in large, continuous blocks that are later cut into sheets, offering versatility and cost-efficiency for general cushioning and packaging. The choice between molded and slabstock foam depends on the required shape precision, durability, and production volume.

Table of Comparison

| Feature | Molded Foam | Slabstock Foam |

|---|---|---|

| Manufacturing Process | Foam is poured into molds for specific shapes. | Foam is produced in large slabs and then cut to size. |

| Customization | High; complex shapes and detailed contours possible. | Moderate; limited to cutting from standard slabs. |

| Density | Controlled precisely within molds for consistency. | Varies across slabs, generally uniform but less precise. |

| Cost | Higher due to molds and labor-intensive process. | Lower; efficient for large volume production. |

| Application | Automotive seating, specialty cushions, protective packaging. | Furniture cushions, mattresses, general padding. |

| Material Waste | Minimal; foam forms directly into shape. | Higher; trimming and cutting waste common. |

Overview of Molded Foam and Slabstock Foam

Molded foam is produced by pouring liquid foam into closed molds, resulting in precise shapes with consistent density and structural integrity ideal for seating, automotive components, and protective packaging. Slabstock foam is created by continuously dispensing foam onto a conveyor, forming large blocks that are later cut into sheets or custom sizes, commonly used for mattresses, cushions, and insulation. Each type offers distinct manufacturing processes and material characteristics tailored to specific applications and performance requirements.

Manufacturing Processes: Molded vs. Slabstock Foam

Molded foam is produced by pouring liquid foam into closed molds where it expands and cures into specific shapes, ensuring precise dimensions and minimal waste. Slabstock foam, in contrast, is manufactured by continuously pouring the foam mixture onto a conveyor belt, where it expands into large foam blocks that are later cut into desired sizes. The molded foam process allows for complex, three-dimensional shapes ideal for specialized applications, while slabstock foam excels in volume production with adaptable thickness and density.

Key Material Properties Comparison

Molded foam exhibits higher density and superior structural integrity compared to slabstock foam, making it ideal for applications requiring precise shaping and durability. Slabstock foam offers greater flexibility and softer cushioning, suitable for general padding and comfort uses due to its open-cell structure. Thermal resistance and resilience rates in molded foam surpass those of slabstock foam, enhancing longevity in high-performance environments.

Application Suitability: Molded vs. Slabstock Foam

Molded foam offers superior contouring and durability, making it ideal for automotive seats, protective gear, and ergonomic cushions where precise shapes are essential. Slabstock foam, generally produced in large blocks, suits applications demanding broad cushioning like mattresses, upholstered furniture, and soundproofing due to its versatility and ease of cutting into various sizes. Choosing between molded and slabstock foam depends on the need for detailed shaping versus expansive, adaptable cushioning solutions.

Cost Analysis and Production Efficiency

Molded foam offers higher production efficiency with automated processes and minimal material waste, leading to lower labor costs compared to slabstock foam, which requires manual cutting and trimming. The initial investment for molded foam machinery is higher, but its precision reduces defects and enhances scalability, optimizing overall cost-effectiveness for large-volume manufacturing. In contrast, slabstock foam is more cost-effective for small-scale or customizable productions due to lower upfront equipment expenses despite increased material scrap and longer production times.

Design Flexibility and Customization Potential

Molded foam offers superior design flexibility with the ability to create complex shapes and detailed contours tailored to specific applications, making it ideal for ergonomic cushioning and automotive seating. Slabstock foam provides broader customization potential in density and firmness but is limited to simpler shapes, often requiring additional cutting or laminating processes to achieve the desired form. Choosing molded foam allows for precise, integrated designs, while slabstock foam excels in adjustable comfort levels through post-production modifications.

Durability and Longevity of Each Foam Type

Molded foam exhibits higher durability due to its denser structure and seamless design, making it resistant to wear and deformation over time. Slabstock foam, while more flexible and softer, tends to compress and degrade faster under sustained pressure, reducing its longevity in high-usage applications. The choice between molded and slabstock foam depends on the specific durability requirements and expected lifespan of the product.

Environmental Impact and Sustainability

Molded foam typically generates less waste during production compared to slabstock foam, which is cut from larger blocks, resulting in higher material offcuts. Molded foam's precision manufacturing methods often allow for better resource efficiency and lower energy consumption, contributing to a reduced carbon footprint. Slabstock foam, while versatile and widely used, tends to have a larger environmental impact due to its bulk processing, higher scrap rates, and challenges in recycling.

Common Industries Using Molded and Slabstock Foams

Molded foam is frequently utilized in automotive seating, packaging, and medical products due to its precise shape and durability, while slabstock foam is prominent in furniture manufacturing, bedding, and carpet underlay for its flexibility and cost-effectiveness. The automotive industry relies on molded foam for ergonomic and safety applications, whereas the furniture industry prefers slabstock foam for cushioning and insulation purposes. Both types of foam serve critical roles in industries requiring tailored comfort, impact absorption, and thermal insulation.

Choosing the Right Foam: Factors to Consider

Choosing between molded foam and slabstock foam depends heavily on the intended application, durability requirements, and budget constraints. Molded foam offers superior structural integrity and resilience, making it ideal for high-impact uses such as automotive seating or specialty cushions, while slabstock foam provides versatile, cost-effective solutions suitable for general upholstery and bedding. Consider factors such as density, firmness, and customization options when selecting foam to ensure optimal comfort, longevity, and performance.

Molded foam vs Slabstock foam Infographic

materialdif.com

materialdif.com