PU foam offers superior elasticity and durability compared to EPS foam, making it ideal for pet beds that require long-lasting comfort and support. EPS foam is lightweight and provides excellent cushioning but lacks the resilience of PU foam, which may lead to faster wear and reduced comfort for active pets. Choosing PU foam ensures better shock absorption and maintains shape over time, enhancing your pet's rest and overall well-being.

Table of Comparison

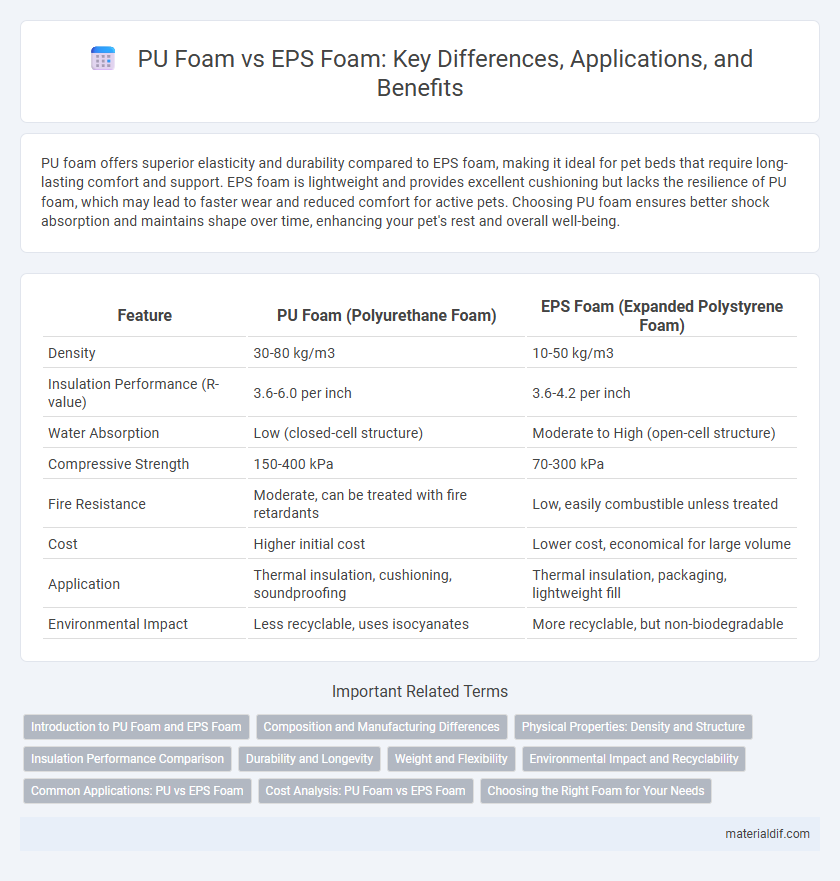

| Feature | PU Foam (Polyurethane Foam) | EPS Foam (Expanded Polystyrene Foam) |

|---|---|---|

| Density | 30-80 kg/m3 | 10-50 kg/m3 |

| Insulation Performance (R-value) | 3.6-6.0 per inch | 3.6-4.2 per inch |

| Water Absorption | Low (closed-cell structure) | Moderate to High (open-cell structure) |

| Compressive Strength | 150-400 kPa | 70-300 kPa |

| Fire Resistance | Moderate, can be treated with fire retardants | Low, easily combustible unless treated |

| Cost | Higher initial cost | Lower cost, economical for large volume |

| Application | Thermal insulation, cushioning, soundproofing | Thermal insulation, packaging, lightweight fill |

| Environmental Impact | Less recyclable, uses isocyanates | More recyclable, but non-biodegradable |

Introduction to PU Foam and EPS Foam

PU foam, or polyurethane foam, is a versatile polymer material known for its excellent insulation, flexibility, and durability, commonly used in furniture, automotive, and construction industries. EPS foam, or expanded polystyrene foam, is a lightweight, rigid cellular plastic primarily utilized for packaging, insulation, and protective applications due to its impact resistance and thermal properties. Both materials offer unique advantages in thermal insulation and cushioning but differ significantly in texture, density, and application scope.

Composition and Manufacturing Differences

PU foam, or polyurethane foam, is produced through a chemical reaction between polyols and diisocyanates, resulting in a flexible or rigid material with a cellular structure formed during polymerization. EPS foam, or expanded polystyrene foam, is made by expanding polystyrene beads using steam, which causes the beads to fuse into a lightweight, rigid foam with closed cells. The fundamental composition difference lies in PU foam's polymeric matrix with urethane linkages compared to EPS foam's polystyrene polymer, while manufacturing methods diverge between chemical reaction processes for PU and physical expansion for EPS.

Physical Properties: Density and Structure

PU foam exhibits a higher density range, typically between 30 to 100 kg/m3, offering superior compressive strength and resilience compared to EPS foam, which has a density range of 10 to 40 kg/m3. The cellular structure of PU foam is closed-cell and more uniform, providing better insulation and moisture resistance, whereas EPS foam consists of expanded polystyrene beads fused together, resulting in a more rigid but less flexible matrix. These physical properties make PU foam ideal for applications requiring durability and flexibility, while EPS foam is favored for lightweight insulation and impact absorption.

Insulation Performance Comparison

PU foam exhibits superior insulation performance compared to EPS foam due to its higher R-value per inch, typically around 6 to 7, which enhances energy efficiency by providing better thermal resistance. EPS foam, with an R-value of approximately 3.6 to 4.2 per inch, is less effective in minimizing heat transfer, making PU foam more suitable for applications requiring stringent insulation standards. The closed-cell structure of PU foam also contributes to its enhanced moisture resistance and durability, further improving its overall thermal insulation capabilities.

Durability and Longevity

PU foam offers superior durability due to its closed-cell structure, which resists moisture, chemicals, and physical compression better than EPS foam. EPS foam, while lightweight and cost-effective, is more prone to cracking and degradation under prolonged exposure to environmental stressors. The longevity of PU foam typically exceeds EPS foam by several years, making it ideal for applications requiring extended performance and structural integrity.

Weight and Flexibility

PU foam weighs significantly less than EPS foam, making it ideal for lightweight applications. PU foam offers superior flexibility, allowing it to compress and return to its original shape without permanent deformation, unlike the more rigid EPS foam. This combination of lower weight and enhanced flexibility makes PU foam preferable in industries requiring cushioning and impact absorption.

Environmental Impact and Recyclability

PU foam, or polyurethane foam, is derived from petrochemicals and presents challenges in waste management due to its chemical composition, which complicates recycling processes and leads to longer environmental persistence. EPS foam, or expanded polystyrene, is lightweight and widely used but is notorious for its environmental impact as it breaks down into microplastics and is less biodegradable, though it can be recycled in specialized facilities. Both foams contribute to pollution, but EPS foam's higher volume in waste streams and limited recycling infrastructure exacerbate its environmental footprint compared to PU foam.

Common Applications: PU vs EPS Foam

PU foam is widely used in furniture cushioning, automotive interiors, and insulation panels due to its superior flexibility and insulating properties. EPS foam is commonly applied in packaging, construction insulation, and lightweight structural components because of its excellent compressive strength and thermal insulation. Both materials serve distinct industries where durability, weight, and insulation requirements vary significantly.

Cost Analysis: PU Foam vs EPS Foam

PU foam typically has a higher initial cost compared to EPS foam due to its more complex manufacturing process and superior insulation properties. EPS foam offers a more budget-friendly option, especially for large-scale projects, while still providing decent thermal performance. Long-term savings with PU foam can occur because of its better durability and energy efficiency, reducing maintenance and energy expenses over time.

Choosing the Right Foam for Your Needs

PU foam offers superior insulation and flexibility, making it ideal for applications requiring high thermal resistance and cushioning, such as furniture and automotive seating. EPS foam is lightweight, cost-effective, and highly resistant to moisture, which suits packaging, insulation panels, and construction needs. Assessing factors like thermal performance, durability, and environmental exposure helps in selecting the right foam type tailored to specific project demands.

PU foam vs EPS foam Infographic

materialdif.com

materialdif.com