Microcellular foam features tiny, uniformly distributed cells that enhance strength, flexibility, and surface finish, making it ideal for precision molding and lightweight applications. Macrocellular foam contains larger cells, providing greater cushioning and insulation properties, commonly used in packaging and thermal barriers. The choice between microcellular and macrocellular foam depends on the balance between mechanical performance and cost-effectiveness required for specific industries.

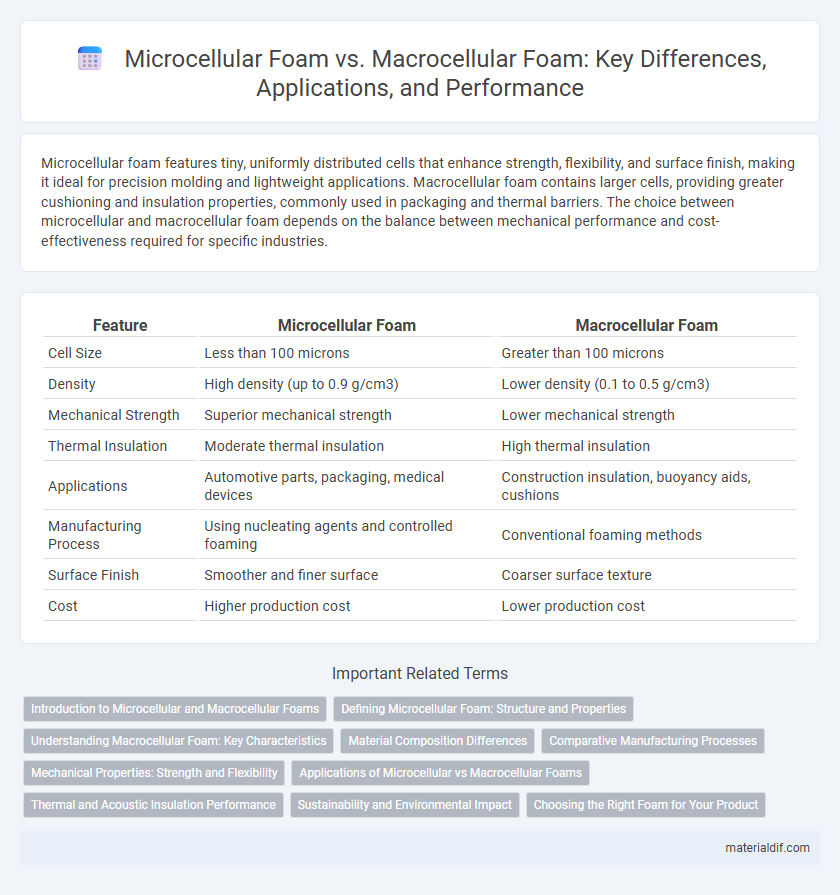

Table of Comparison

| Feature | Microcellular Foam | Macrocellular Foam |

|---|---|---|

| Cell Size | Less than 100 microns | Greater than 100 microns |

| Density | High density (up to 0.9 g/cm3) | Lower density (0.1 to 0.5 g/cm3) |

| Mechanical Strength | Superior mechanical strength | Lower mechanical strength |

| Thermal Insulation | Moderate thermal insulation | High thermal insulation |

| Applications | Automotive parts, packaging, medical devices | Construction insulation, buoyancy aids, cushions |

| Manufacturing Process | Using nucleating agents and controlled foaming | Conventional foaming methods |

| Surface Finish | Smoother and finer surface | Coarser surface texture |

| Cost | Higher production cost | Lower production cost |

Introduction to Microcellular and Macrocellular Foams

Microcellular foam features a fine cell structure with cell sizes typically below 100 microns, resulting in enhanced mechanical properties and reduced material density. Macrocellular foam contains larger, visible cells generally exceeding 1 millimeter, offering greater cushioning and shock absorption but lower tensile strength. The choice between microcellular and macrocellular foam depends on application-specific requirements such as durability, weight, and impact resistance.

Defining Microcellular Foam: Structure and Properties

Microcellular foam features a fine cellular structure with cell sizes typically below 50 microns, resulting in a higher surface area and improved mechanical properties compared to macrocellular foam. This foam type offers enhanced energy absorption, reduced density, and superior thermal insulation due to its uniform, small cells. The dense network of microcells also provides better dimensional stability and resistance to deformation under stress.

Understanding Macrocellular Foam: Key Characteristics

Macrocellular foam features larger cells typically exceeding 300 microns in diameter, resulting in a less dense and more rigid structure compared to microcellular foam. Its higher permeability allows for enhanced fluid flow, making it ideal for applications such as thermal insulation, cushioning, and filtration. The mechanical properties of macrocellular foam emphasize durability and shock absorption, advantageous in packaging and automotive industries.

Material Composition Differences

Microcellular foam consists of finer cells with diameters typically less than 50 microns, created through nucleation in polymer matrices such as polyurethane or polystyrene, resulting in higher density and uniform material distribution. Macrocellular foam features larger cells often exceeding 100 microns, produced via chemical blowing agents in materials like polyethylene or polypropylene, which yield lower density and enhanced cushioning properties. The material composition differences directly influence mechanical strength, thermal insulation, and acoustic absorption capacities between microcellular and macrocellular foams.

Comparative Manufacturing Processes

Microcellular foam is produced through a precise nucleation process involving high-pressure gas saturation and rapid depressurization, resulting in uniform, fine cells typically less than 50 microns in diameter. Macrocellular foam manufacturing relies on traditional polymer foaming techniques, such as chemical blowing agents or mechanical frothing, creating larger, irregular cells ranging from hundreds to thousands of microns. The controlled environment and advanced equipment required for microcellular foam enable superior mechanical properties and material efficiency compared to the simpler, cost-effective processes used for macrocellular foam production.

Mechanical Properties: Strength and Flexibility

Microcellular foam exhibits higher strength and enhanced flexibility due to its smaller, uniformly distributed cell structure, which distributes stress more evenly and reduces the likelihood of fracture. Macrocellular foam, with its larger cell size, typically offers lower mechanical strength but provides greater cushioning and impact absorption. The choice between microcellular and macrocellular foam depends on application-specific requirements for durability and flexibility in sectors such as automotive, packaging, and biomedical devices.

Applications of Microcellular vs Macrocellular Foams

Microcellular foams feature small, uniform cells ideal for precision applications like automotive components, electronics, and medical devices due to their enhanced mechanical properties and surface finish. Macrocellular foams possess larger cells, providing superior cushioning and insulation qualities, making them suitable for packaging, furniture, and thermal insulation in construction. The choice between microcellular and macrocellular foams depends on application-specific requirements such as density, strength, and thermal performance.

Thermal and Acoustic Insulation Performance

Microcellular foam exhibits superior thermal insulation properties due to its smaller, more uniform cell structure that minimizes heat transfer through conduction and convection. In contrast, macrocellular foam, with larger cells, offers enhanced acoustic insulation by effectively trapping sound waves and reducing noise transmission. Selecting between microcellular and macrocellular foam depends on prioritizing either heat retention or sound attenuation in insulation applications.

Sustainability and Environmental Impact

Microcellular foam features smaller, more uniformly distributed cells that enhance material efficiency by reducing raw material consumption and waste, making it a sustainable choice. Macrocellular foam, with larger, irregular cells, often requires more polymer and energy to produce, leading to a higher environmental footprint. Optimizing foam cell structure in microcellular technology supports lower greenhouse gas emissions and improved recyclability, crucial for eco-friendly manufacturing.

Choosing the Right Foam for Your Product

Microcellular foam features smaller, uniform cells that provide enhanced strength, cushioning, and resistance to compression, making it ideal for applications requiring durability and lightweight properties. Macrocellular foam contains larger, more open cells, offering superior ventilation, flexibility, and softer texture, suitable for comfort-focused products like mattresses and upholstery. Selecting the right foam depends on balancing factors such as load-bearing capacity, breathability, and product longevity in line with specific performance requirements.

Microcellular foam vs Macrocellular foam Infographic

materialdif.com

materialdif.com