Expanded foam features a cellular structure formed by blowing agents that create numerous small air pockets, resulting in lightweight and flexible material ideal for insulation and cushioning. Extruded foam is produced through a continuous extrusion process that generates a closed-cell structure, offering superior moisture resistance, higher density, and enhanced mechanical strength compared to expanded foam. Choosing between expanded and extruded foam depends on the specific application requirements such as thermal insulation, durability, and environmental exposure.

Table of Comparison

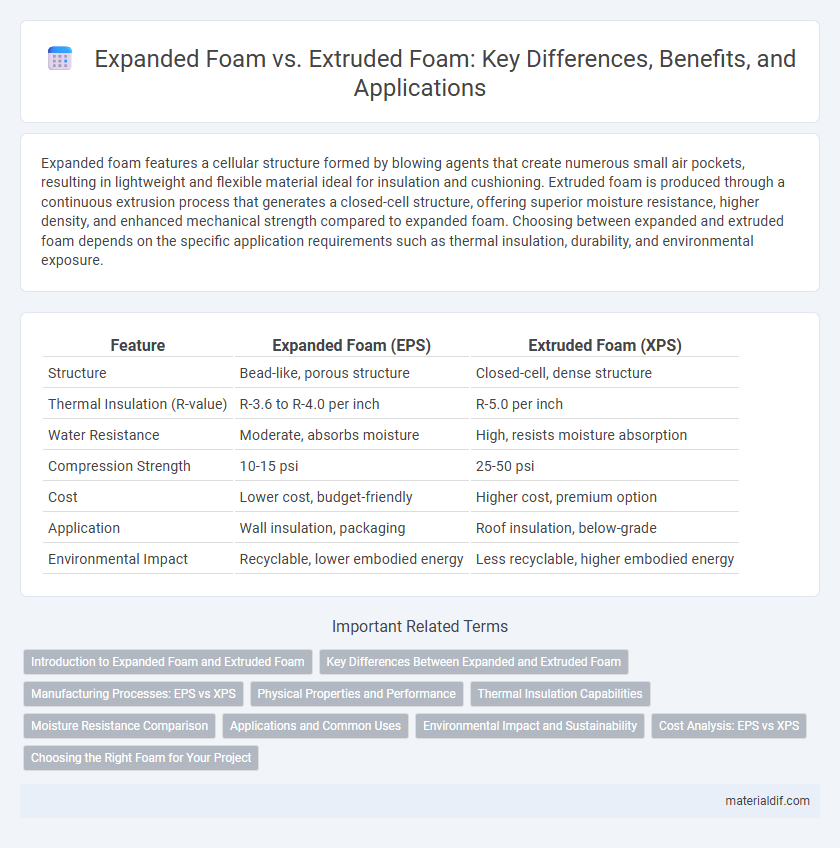

| Feature | Expanded Foam (EPS) | Extruded Foam (XPS) |

|---|---|---|

| Structure | Bead-like, porous structure | Closed-cell, dense structure |

| Thermal Insulation (R-value) | R-3.6 to R-4.0 per inch | R-5.0 per inch |

| Water Resistance | Moderate, absorbs moisture | High, resists moisture absorption |

| Compression Strength | 10-15 psi | 25-50 psi |

| Cost | Lower cost, budget-friendly | Higher cost, premium option |

| Application | Wall insulation, packaging | Roof insulation, below-grade |

| Environmental Impact | Recyclable, lower embodied energy | Less recyclable, higher embodied energy |

Introduction to Expanded Foam and Extruded Foam

Expanded foam is a lightweight material created by expanding polymer beads through steam, resulting in a cellular structure with excellent insulation and cushioning properties. Extruded foam is produced by melting and forcing polymers through a die, creating a uniform, dense, and closed-cell structure that offers superior moisture resistance and structural strength. Both types serve diverse applications in packaging, insulation, and construction, with expanded foam favored for its cost-effectiveness and extruded foam valued for durability and performance.

Key Differences Between Expanded and Extruded Foam

Expanded foam consists of small, closed cells formed by expanding a polymer resin with a blowing agent, resulting in a lightweight material with excellent thermal insulation and sound absorption properties. Extruded foam is produced by melting and forcing polymer through a die to create a dense, homogeneous structure with higher compressive strength and moisture resistance. Key differences include manufacturing processes, cell structure--expanded foam has variable, less dense cells while extruded foam features uniform, closed cells--and performance characteristics like durability, insulation efficiency, and cost.

Manufacturing Processes: EPS vs XPS

Expanded Polystyrene (EPS) is manufactured by expanding polystyrene beads with steam and molding them into blocks or shapes, resulting in a lightweight foam with a bead-like structure. Extruded Polystyrene (XPS) is produced by melting polystyrene pellets and forcing the molten material through a die, creating a dense, closed-cell foam with a uniform texture. EPS's bead expansion process yields lower density and thermal resistance compared to XPS's extrusion method, which provides superior moisture resistance and compressive strength.

Physical Properties and Performance

Expanded foam, characterized by its open-cell structure, offers excellent cushioning and breathability but lower density and compressive strength compared to extruded foam. Extruded foam features a closed-cell, uniform structure that delivers superior moisture resistance, higher durability, and greater thermal insulation. Its dense composition enhances impact absorption and load-bearing capacity, making it ideal for structural and insulation applications.

Thermal Insulation Capabilities

Expanded foam offers superior thermal insulation due to its closed-cell structure that traps air effectively, reducing heat transfer. Extruded foam provides consistent density and moisture resistance, enhancing long-term insulation performance in humid conditions. Both materials excel in energy efficiency, but expanded foam's microcellular composition typically delivers higher R-values per inch.

Moisture Resistance Comparison

Expanded foam features a porous structure that absorbs moisture more readily, resulting in lower moisture resistance compared to extruded foam. Extruded foam boasts a closed-cell structure, providing superior moisture resistance and preventing water infiltration effectively. This makes extruded foam ideal for applications requiring long-term durability in wet or humid environments.

Applications and Common Uses

Expanded foam is widely used in packaging, insulation, and cushioning applications due to its lightweight and excellent shock absorption properties. Extruded foam offers higher density and uniform cell structure, making it ideal for structural insulation, seals, gaskets, and thermal insulation in construction and automotive industries. Both foam types provide effective thermal resistance, but extruded foam's durability and moisture resistance expand its use in outdoor and high-performance environments.

Environmental Impact and Sustainability

Expanded foam, primarily made from polystyrene beads, has a lower density and is more prone to generating microplastics during degradation, posing greater risks to ecosystems. Extruded foam, often made from polyethylene or polystyrene, offers better recyclability and durability, reducing waste and demand for frequent replacement. Both types contribute to environmental pollution, but extruded foam's closed-cell structure enhances insulation efficiency, leading to energy savings and a smaller carbon footprint over time.

Cost Analysis: EPS vs XPS

Expanded Polystyrene (EPS) typically costs less than Extruded Polystyrene (XPS) due to its simpler manufacturing process and lower material density. Despite the higher price, XPS offers superior insulation performance and moisture resistance, which can reduce long-term energy and maintenance costs. Evaluating project requirements and lifespan expenses is crucial when comparing the initial investment of EPS versus XPS foam insulation.

Choosing the Right Foam for Your Project

Expanded foam offers excellent insulation and cushioning with a lightweight, porous structure ideal for packaging and thermal insulation. Extruded foam provides higher density and superior moisture resistance, making it suitable for structural applications and outdoor use. Selecting the right foam depends on project requirements such as durability, moisture exposure, and thermal performance.

Expanded Foam vs Extruded Foam Infographic

materialdif.com

materialdif.com