EVA foam offers superior flexibility and resilience, making it ideal for applications requiring impact absorption and comfort, whereas XPS foam provides excellent thermal insulation and moisture resistance, often used in construction and insulation panels. EVA foam is lightweight and resistant to cracking, while XPS foam boasts a rigid, closed-cell structure that enhances durability and compressive strength. Choosing between EVA and XPS foam depends on whether flexibility or insulation performance is the primary need.

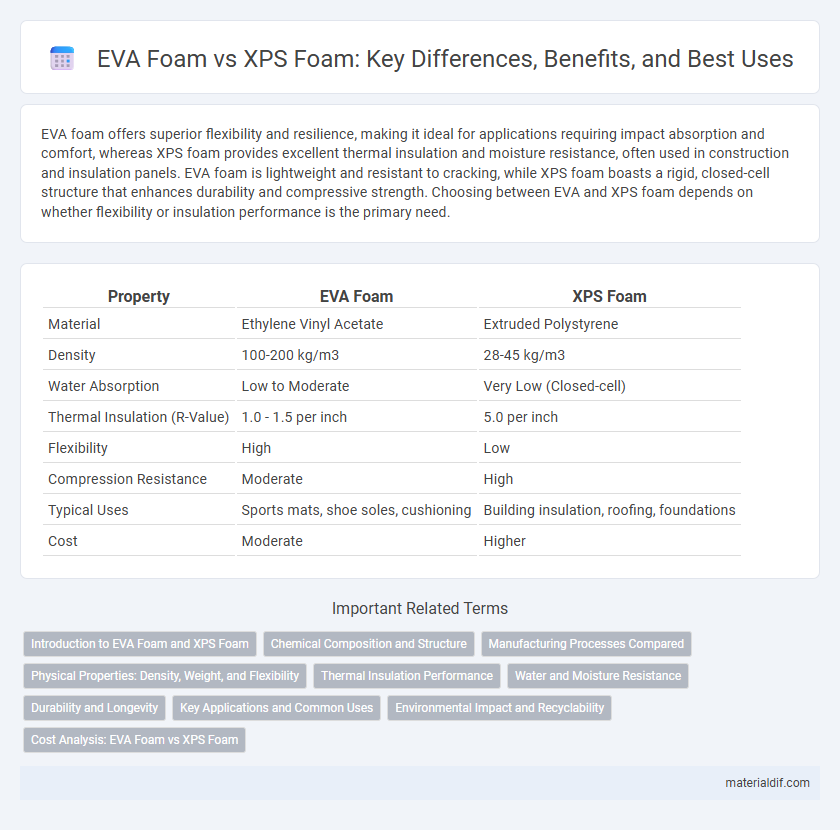

Table of Comparison

| Property | EVA Foam | XPS Foam |

|---|---|---|

| Material | Ethylene Vinyl Acetate | Extruded Polystyrene |

| Density | 100-200 kg/m3 | 28-45 kg/m3 |

| Water Absorption | Low to Moderate | Very Low (Closed-cell) |

| Thermal Insulation (R-Value) | 1.0 - 1.5 per inch | 5.0 per inch |

| Flexibility | High | Low |

| Compression Resistance | Moderate | High |

| Typical Uses | Sports mats, shoe soles, cushioning | Building insulation, roofing, foundations |

| Cost | Moderate | Higher |

Introduction to EVA Foam and XPS Foam

EVA foam, or Ethylene Vinyl Acetate foam, is a flexible, durable material widely used in footwear, sports equipment, and cushioning applications due to its excellent shock absorption and lightweight properties. XPS foam, or Extruded Polystyrene foam, is a rigid insulation material known for its high compressive strength, moisture resistance, and thermal insulation efficiency, commonly used in construction and building applications. Both foams serve distinct purposes: EVA is favored for comfort and flexibility, while XPS is preferred for structural insulation and durability.

Chemical Composition and Structure

EVA foam is primarily composed of ethylene vinyl acetate copolymers, featuring a soft, flexible, and closed-cell structure that offers excellent shock absorption and resilience. XPS foam consists of extruded polystyrene polymers with a rigid, closed-cell structure providing high compressive strength, moisture resistance, and thermal insulation. The chemical composition differences result in EVA's elasticity and cushioning, while XPS's molecular structure delivers durability and superior insulation properties.

Manufacturing Processes Compared

EVA foam is produced through a polymerization process that blends ethylene and vinyl acetate monomers, resulting in a flexible, closed-cell structure ideal for shock absorption and cushioning applications. XPS foam is manufactured using an extrusion process that forces molten polystyrene through a die, creating a rigid, highly insulative foam with a consistent closed-cell structure suitable for thermal insulation in construction. The distinct manufacturing techniques directly influence the foam's density, mechanical properties, and suitability for different industrial uses.

Physical Properties: Density, Weight, and Flexibility

EVA foam exhibits lower density, typically around 48-96 kg/m3, resulting in a lighter and more flexible material compared to XPS foam, which ranges from 28-45 kg/m3 but is more rigid and less flexible. The closed-cell structure of XPS foam provides higher compressive strength and moisture resistance, making it suitable for insulation, while EVA foam's elastic nature makes it ideal for cushioning and shock absorption applications. Weight differences are significant, with EVA foam being lightweight yet more adaptable under stress, whereas XPS foam is denser and firmer, offering better structural support.

Thermal Insulation Performance

EVA foam offers moderate thermal insulation with a typical R-value around 1.5 to 2.0 per inch, making it suitable for applications requiring lightweight and impact-resistant materials. XPS foam provides superior thermal insulation, boasting R-values between 4.5 to 5.0 per inch, which effectively reduces heat transfer and enhances energy efficiency in building envelopes. The closed-cell structure of XPS foam ensures better moisture resistance and long-term thermal performance compared to the more flexible and softer EVA foam.

Water and Moisture Resistance

EVA foam exhibits excellent water resistance due to its closed-cell structure, making it highly effective at preventing moisture absorption and ideal for wet environments. XPS foam also offers superior moisture resistance with low water absorption rates and a dense closed-cell composition, providing reliable insulation even in high-humidity conditions. Both foams maintain dimensional stability when exposed to water, but XPS foam typically outperforms EVA foam in long-term moisture resistance and durability.

Durability and Longevity

EVA foam exhibits superior durability due to its excellent flexibility and resistance to cracking, making it ideal for applications requiring repeated impact absorption. XPS foam offers high compressive strength and moisture resistance, ensuring long-lasting thermal insulation in construction environments. Both foams deliver notable longevity, but EVA foam tends to outperform in wear-intensive uses, while XPS excels in moisture-heavy conditions.

Key Applications and Common Uses

EVA foam is widely used in sports equipment, footwear insoles, and cushioning due to its flexibility, shock absorption, and lightweight properties. XPS foam is primarily utilized in construction for insulation, roofing, and structural panels because of its high compressive strength, moisture resistance, and thermal insulation capabilities. Both foams serve specialized purposes where EVA excels in comfort and impact protection, while XPS provides durability and energy efficiency in building applications.

Environmental Impact and Recyclability

EVA foam contains ethylene-vinyl acetate, which is partially recyclable but often ends in landfills due to limited recycling facilities, impacting its environmental footprint. XPS foam, made from extruded polystyrene, poses significant environmental challenges due to its non-biodegradability and difficulty in recycling, contributing to long-term pollution. Both foams release greenhouse gases during production, but XPS has a higher global warming potential due to the blowing agents used, making EVA a somewhat greener option.

Cost Analysis: EVA Foam vs XPS Foam

EVA foam typically costs more per square foot compared to XPS foam, reflecting its superior flexibility and durability in cushioning applications. XPS foam offers a more budget-friendly option, with prices generally lower due to its rigid structure and widespread use in insulation. When evaluating cost-effectiveness, consider the required foam properties alongside initial purchase price and long-term performance in specific projects.

EVA foam vs XPS foam Infographic

materialdif.com

materialdif.com