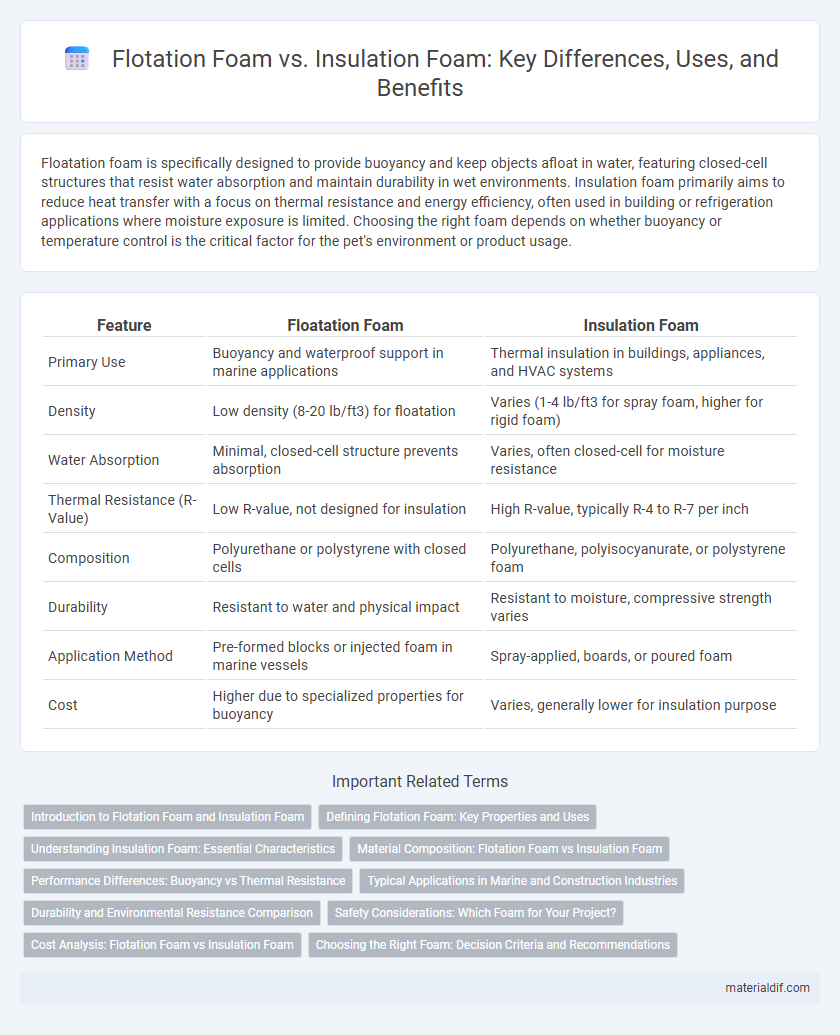

Floatation foam is specifically designed to provide buoyancy and keep objects afloat in water, featuring closed-cell structures that resist water absorption and maintain durability in wet environments. Insulation foam primarily aims to reduce heat transfer with a focus on thermal resistance and energy efficiency, often used in building or refrigeration applications where moisture exposure is limited. Choosing the right foam depends on whether buoyancy or temperature control is the critical factor for the pet's environment or product usage.

Table of Comparison

| Feature | Floatation Foam | Insulation Foam |

|---|---|---|

| Primary Use | Buoyancy and waterproof support in marine applications | Thermal insulation in buildings, appliances, and HVAC systems |

| Density | Low density (8-20 lb/ft3) for floatation | Varies (1-4 lb/ft3 for spray foam, higher for rigid foam) |

| Water Absorption | Minimal, closed-cell structure prevents absorption | Varies, often closed-cell for moisture resistance |

| Thermal Resistance (R-Value) | Low R-value, not designed for insulation | High R-value, typically R-4 to R-7 per inch |

| Composition | Polyurethane or polystyrene with closed cells | Polyurethane, polyisocyanurate, or polystyrene foam |

| Durability | Resistant to water and physical impact | Resistant to moisture, compressive strength varies |

| Application Method | Pre-formed blocks or injected foam in marine vessels | Spray-applied, boards, or poured foam |

| Cost | Higher due to specialized properties for buoyancy | Varies, generally lower for insulation purpose |

Introduction to Flotation Foam and Insulation Foam

Flotation foam is a lightweight, closed-cell material designed to provide buoyancy and prevent water absorption in marine and safety applications. Insulation foam primarily consists of rigid or semi-rigid panels that offer high thermal resistance, reducing heat transfer in buildings, appliances, and industrial systems. Both types of foam utilize different chemical compositions and structures tailored to their specific performance requirements.

Defining Flotation Foam: Key Properties and Uses

Flotation foam is a specialized closed-cell foam designed to provide buoyancy by trapping gas bubbles within its structure, making it highly effective for marine applications and watercraft safety. Key properties include low water absorption, high compressive strength, and excellent durability in wet environments, distinguishing it from insulation foam that primarily focuses on thermal resistance. Its primary uses encompass life jackets, boat hulls, and flotation devices, where maintaining buoyancy and structural integrity in aquatic conditions is critical.

Understanding Insulation Foam: Essential Characteristics

Insulation foam is designed to minimize heat transfer, providing excellent thermal resistance with a high R-value that enhances energy efficiency in buildings. This foam type is typically closed-cell, which prevents moisture absorption and offers structural rigidity, making it ideal for walls, roofs, and foundations. Unlike flotation foam, insulation foam prioritizes temperature control and moisture barrier properties over buoyancy and water displacement.

Material Composition: Flotation Foam vs Insulation Foam

Flotation foam primarily consists of closed-cell polyethylene or polypropylene, providing buoyancy and water resistance essential for marine and safety applications. Insulation foam is typically made from polyurethane or polystyrene, designed with a cellular structure that traps air to minimize heat transfer and enhance energy efficiency. The key difference lies in flotation foam's emphasis on durability and water repellency, whereas insulation foam prioritizes thermal resistance and structural rigidity.

Performance Differences: Buoyancy vs Thermal Resistance

Floatation foam exhibits superior buoyancy due to its closed-cell structure that traps air, making it ideal for applications requiring water displacement and durability in aquatic environments. Insulation foam, characterized by its thermal resistance properties, uses materials like polyurethane or polystyrene to minimize heat transfer and enhance energy efficiency in buildings. The performance difference hinges on floatation foam's emphasis on low density and water resistance, while insulation foam prioritizes thermal conductivity and fire retardancy.

Typical Applications in Marine and Construction Industries

Floatation foam is primarily used in marine applications for buoyancy and safety, ensuring vessels remain afloat even when compromised, while insulation foam is common in construction for thermal regulation and energy efficiency in buildings. Marine industries rely on closed-cell floatation foam for durability against water absorption, whereas construction utilizes rigid or spray polyurethane insulation foam to enhance structural thermal performance. Both foams are engineered for industry-specific demands, optimizing safety and comfort in their respective environments.

Durability and Environmental Resistance Comparison

Floatation foam exhibits superior durability and environmental resistance compared to insulation foam, making it ideal for marine and aquatic applications where prolonged exposure to water, UV rays, and temperature fluctuations is common. This type of foam maintains structural integrity and buoyancy over time, resisting water absorption, corrosion, and biological degradation. Insulation foam, while effective in thermal resistance, typically shows less resilience against moisture and harsh environmental elements, leading to reduced longevity in outdoor or wet conditions.

Safety Considerations: Which Foam for Your Project?

Floatation foam, designed for buoyancy and water resistance, is non-toxic and fire-retardant, making it ideal for marine safety applications requiring both stability and compliance with safety standards. Insulation foam emphasizes thermal resistance and often includes additives to enhance fire retardancy; however, some types emit hazardous fumes if burned or improperly installed, posing risks in enclosed or poorly ventilated spaces. Selecting the appropriate foam involves assessing exposure conditions, fire safety regulations, and chemical emissions to ensure both project performance and occupant safety.

Cost Analysis: Flotation Foam vs Insulation Foam

Flotation foam typically incurs higher upfront costs due to its specialized closed-cell structure designed for buoyancy and water resistance, making it ideal for marine and safety applications. Insulation foam, often made from materials like polyurethane or polystyrene, provides cost-effective thermal resistance and energy savings in construction and HVAC systems. The overall cost efficiency depends on the application's performance requirements, with flotation foam justified by durability and safety benefits, while insulation foam emphasizes long-term energy cost reductions.

Choosing the Right Foam: Decision Criteria and Recommendations

Selecting the appropriate foam requires assessing key factors such as density, water resistance, and thermal insulation properties. Floatation foam, characterized by low density and high buoyancy, is ideal for marine and safety applications, while insulation foam excels in thermal resistance for construction and HVAC systems. Evaluating project-specific needs and environmental conditions guides the optimal foam choice, ensuring performance efficiency and durability.

Floatation Foam vs Insulation Foam Infographic

materialdif.com

materialdif.com