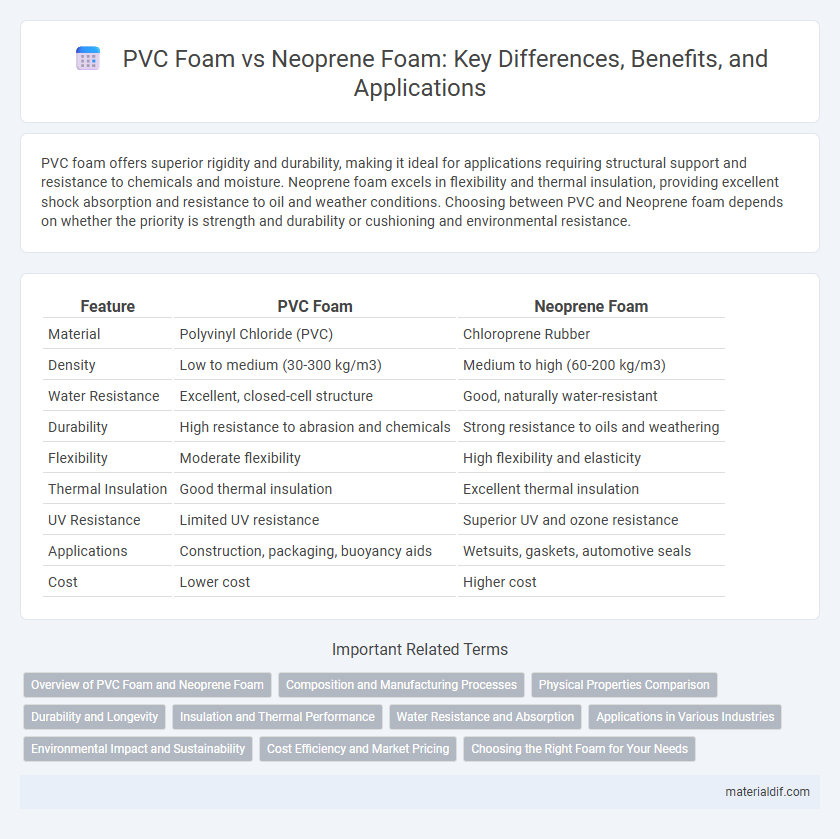

PVC foam offers superior rigidity and durability, making it ideal for applications requiring structural support and resistance to chemicals and moisture. Neoprene foam excels in flexibility and thermal insulation, providing excellent shock absorption and resistance to oil and weather conditions. Choosing between PVC and Neoprene foam depends on whether the priority is strength and durability or cushioning and environmental resistance.

Table of Comparison

| Feature | PVC Foam | Neoprene Foam |

|---|---|---|

| Material | Polyvinyl Chloride (PVC) | Chloroprene Rubber |

| Density | Low to medium (30-300 kg/m3) | Medium to high (60-200 kg/m3) |

| Water Resistance | Excellent, closed-cell structure | Good, naturally water-resistant |

| Durability | High resistance to abrasion and chemicals | Strong resistance to oils and weathering |

| Flexibility | Moderate flexibility | High flexibility and elasticity |

| Thermal Insulation | Good thermal insulation | Excellent thermal insulation |

| UV Resistance | Limited UV resistance | Superior UV and ozone resistance |

| Applications | Construction, packaging, buoyancy aids | Wetsuits, gaskets, automotive seals |

| Cost | Lower cost | Higher cost |

Overview of PVC Foam and Neoprene Foam

PVC foam is a closed-cell, rigid material known for its excellent chemical resistance, durability, and lightweight properties, making it ideal for marine, construction, and signage applications. Neoprene foam, or polychloroprene, offers superior flexibility, thermal insulation, and weather resistance, commonly used in wetsuits, gaskets, and protective apparel. Both foams provide effective cushioning and water resistance, but PVC foam excels in structural support while neoprene foam is preferred for elasticity and temperature durability.

Composition and Manufacturing Processes

PVC foam is composed primarily of polyvinyl chloride combined with plasticizers, stabilizers, and blowing agents, produced through a extrusion or free-rise molding process that creates a closed-cell structure. Neoprene foam consists of polychloroprene elastomers, manufactured by a polymerization process followed by foaming with gas expansion or chemical blowing agents, resulting in an open or closed-cell structure depending on formulation. The distinct chemical compositions influence the manufacturing methods, where PVC foam's rigid polymer matrix contrasts with neoprene's flexible elastomeric nature, affecting their respective density, durability, and insulation properties.

Physical Properties Comparison

PVC foam exhibits higher rigidity and superior chemical resistance compared to neoprene foam, making it ideal for structural applications requiring durability. Neoprene foam offers greater flexibility, excellent resistance to oil, and superior thermal insulation properties suited for dynamic environments. Density-wise, PVC foam typically ranges from 50 to 200 kg/m3, while neoprene foam density varies between 70 and 200 kg/m3, influencing their respective compressive strengths and cushioning capabilities.

Durability and Longevity

PVC foam exhibits superior durability and longevity compared to neoprene foam due to its enhanced resistance to abrasion, chemicals, and UV exposure. Neoprene foam tends to degrade faster when exposed to prolonged sunlight and harsh environmental conditions, limiting its lifespan in outdoor applications. The molecular structure of PVC foam provides greater stability, maintaining its physical properties over extended use and under varying temperatures.

Insulation and Thermal Performance

PVC foam provides excellent thermal insulation due to its closed-cell structure, which minimizes heat transfer and maintains consistent temperature control. Neoprene foam also offers strong insulation properties but excels in thermal performance by resisting temperature fluctuations and maintaining flexibility under varying conditions. The choice between PVC and Neoprene foam depends on specific insulation requirements, with PVC favored for rigid thermal barriers and Neoprene preferred for dynamic thermal environments.

Water Resistance and Absorption

PVC foam offers superior water resistance due to its closed-cell structure, preventing water absorption and maintaining buoyancy even after prolonged exposure. Neoprene foam, while also water-resistant, has an open-cell composition that allows minimal water absorption, leading to slight weight gain over time. This makes PVC foam more suitable for applications requiring durable, consistently dry materials in wet environments.

Applications in Various Industries

PVC foam excels in marine, construction, and automotive industries due to its rigidity, water resistance, and chemical stability, making it ideal for insulation, buoyancy aids, and structural components. Neoprene foam offers superior flexibility, weather resistance, and cushioning, widely used in sports equipment, wetsuits, and protective gear manufacturing. Both materials cater to specialized industrial needs, with PVC preferred for durability and Neoprene for comfort and impact absorption.

Environmental Impact and Sustainability

PVC foam generates more environmental concerns due to its production process involving toxic chlorine-based chemicals and challenges in recycling, often resulting in persistent pollutants. Neoprene foam, while also synthetic, has a comparatively lower environmental footprint as newer manufacturing methods reduce emissions and improved recycling technologies are emerging. Sustainable alternatives favor neoprene with certifications supporting eco-friendlier formulations and biodegradability potential, making it a preferable choice for reducing long-term ecological impact.

Cost Efficiency and Market Pricing

PVC foam offers superior cost efficiency compared to neoprene foam due to its lower production expenses and longer lifespan, making it a budget-friendly option for manufacturers. Market pricing for PVC foam generally remains stable and affordable, while neoprene foam experiences higher prices linked to its specialized chemical properties and demand in niche markets. Businesses prioritize PVC foam to optimize operational costs without sacrificing performance in applications like insulation and packaging.

Choosing the Right Foam for Your Needs

PVC foam offers excellent chemical resistance, durability, and is lightweight, making it ideal for applications requiring structural support and exposure to harsh environments. Neoprene foam provides superior flexibility, thermal insulation, and resistance to oils and weathering, which suits uses in cushioning, gaskets, and wetsuits. Selecting the right foam depends on factors like environmental exposure, mechanical stress, and required elasticity, ensuring optimal performance and longevity for specific applications.

PVC foam vs Neoprene foam Infographic

materialdif.com

materialdif.com