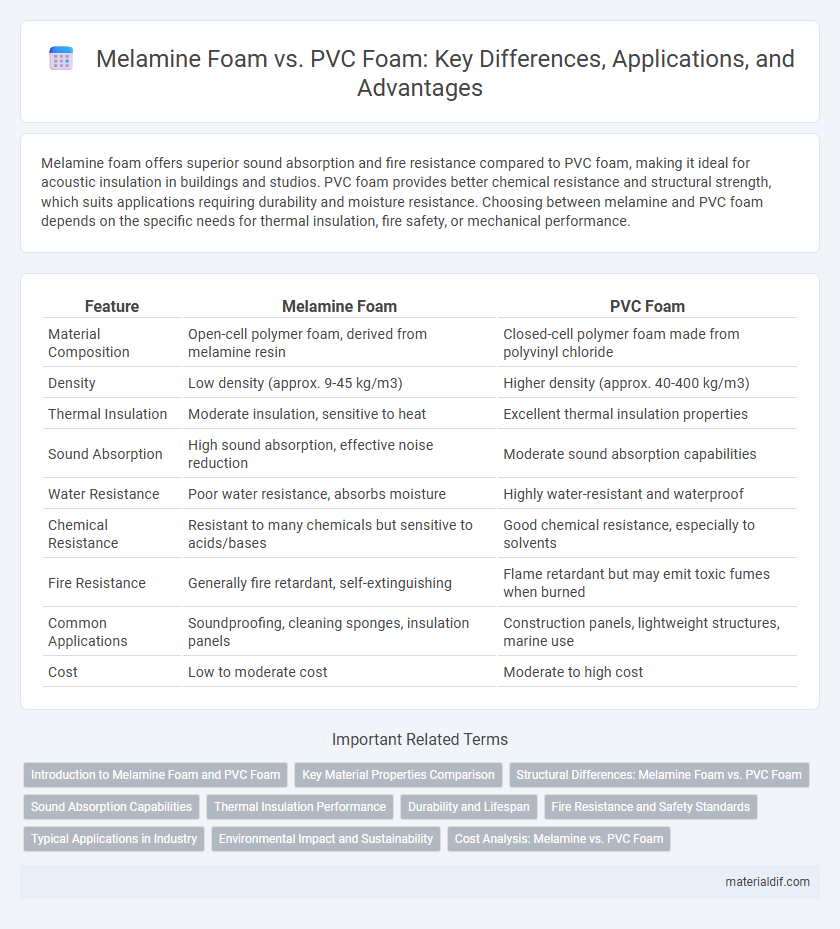

Melamine foam offers superior sound absorption and fire resistance compared to PVC foam, making it ideal for acoustic insulation in buildings and studios. PVC foam provides better chemical resistance and structural strength, which suits applications requiring durability and moisture resistance. Choosing between melamine and PVC foam depends on the specific needs for thermal insulation, fire safety, or mechanical performance.

Table of Comparison

| Feature | Melamine Foam | PVC Foam |

|---|---|---|

| Material Composition | Open-cell polymer foam, derived from melamine resin | Closed-cell polymer foam made from polyvinyl chloride |

| Density | Low density (approx. 9-45 kg/m3) | Higher density (approx. 40-400 kg/m3) |

| Thermal Insulation | Moderate insulation, sensitive to heat | Excellent thermal insulation properties |

| Sound Absorption | High sound absorption, effective noise reduction | Moderate sound absorption capabilities |

| Water Resistance | Poor water resistance, absorbs moisture | Highly water-resistant and waterproof |

| Chemical Resistance | Resistant to many chemicals but sensitive to acids/bases | Good chemical resistance, especially to solvents |

| Fire Resistance | Generally fire retardant, self-extinguishing | Flame retardant but may emit toxic fumes when burned |

| Common Applications | Soundproofing, cleaning sponges, insulation panels | Construction panels, lightweight structures, marine use |

| Cost | Low to moderate cost | Moderate to high cost |

Introduction to Melamine Foam and PVC Foam

Melamine foam is a lightweight, open-cell material known for its excellent sound absorption, thermal insulation, and fire-resistant properties, often used in acoustic panels and cleaning products. PVC foam, on the other hand, is a durable, closed-cell plastic foam valued for its impact resistance, moisture resistance, and structural stability, commonly applied in construction and marine industries. Both materials differ significantly in composition and performance, with melamine foam excelling in insulation and acoustics, while PVC foam offers superior mechanical strength and weather resistance.

Key Material Properties Comparison

Melamine foam offers exceptional thermal insulation and fire resistance due to its open-cell structure and melamine resin composition, making it ideal for acoustic applications. PVC foam exhibits superior mechanical strength and chemical resistance, attributed to its closed-cell structure and polyvinyl chloride base, making it suitable for structural and marine uses. Both foams differ significantly in density, compressive strength, and water absorption, influencing their performance across industries.

Structural Differences: Melamine Foam vs. PVC Foam

Melamine foam features an open-cell microstructure composed of a rigid thermosetting resin, providing exceptional sound absorption and thermal insulation properties. PVC foam consists of a closed-cell structure made from polyvinyl chloride, offering higher density and greater mechanical strength but reduced acoustic performance. The porous network of melamine foam enables superior airflow and noise reduction, while the dense PVC foam excels in durability and resistance to moisture and chemicals.

Sound Absorption Capabilities

Melamine foam exhibits superior sound absorption capabilities due to its open-cell structure, effectively reducing mid to high-frequency noise. PVC foam, with its denser and closed-cell design, provides limited sound absorption but excels in impact resistance and insulation. For acoustic applications requiring efficient noise dampening, melamine foam is the preferred choice over PVC foam.

Thermal Insulation Performance

Melamine foam offers superior thermal insulation due to its open-cell structure, which effectively traps air and reduces heat transfer. In contrast, PVC foam, characterized by its closed-cell composition, provides moderate insulation but excels in moisture resistance and durability. Melamine foam's low thermal conductivity makes it ideal for applications requiring efficient temperature control.

Durability and Lifespan

Melamine foam offers superior durability due to its rigid, open-cell structure, maintaining performance under frequent use and exposure to solvents and heat. PVC foam, while versatile and resistant to moisture and chemicals, tends to degrade faster under UV exposure and mechanical stress. Consequently, melamine foam typically provides a longer lifespan in demanding cleaning and insulation applications compared to PVC foam.

Fire Resistance and Safety Standards

Melamine foam offers superior fire resistance due to its intrinsic ability to char and self-extinguish, aligning with stringent fire safety standards such as ASTM E84 Class A. In contrast, PVC foam tends to melt and emit toxic fumes when exposed to high temperatures, posing greater safety risks in fire scenarios. Choosing melamine foam enhances fire safety compliance in applications requiring non-flammable, low-smoke materials.

Typical Applications in Industry

Melamine foam is widely used in the automotive and construction industries for sound absorption and thermal insulation due to its open-cell structure and fire-resistant properties. PVC foam finds typical applications in marine, signage, and furniture sectors because of its density, durability, and excellent chemical resistance. Both foams serve key roles in packaging and lightweight structural components, with melamine foam favored for acoustic solutions and PVC foam preferred for impact-resistant and waterproof applications.

Environmental Impact and Sustainability

Melamine foam is highly valued for its biodegradability and low environmental footprint due to its organic composition, which decomposes more efficiently than synthetic alternatives. PVC foam, derived from polyvinyl chloride, poses significant sustainability challenges as it releases harmful dioxins during production and disposal, contributing to long-term pollution and limited recyclability. Choosing melamine foam promotes eco-friendly practices by reducing toxic emissions and supporting waste reduction in comparison to PVC foam.

Cost Analysis: Melamine vs. PVC Foam

Melamine foam generally incurs higher production costs due to its specialized manufacturing process and superior acoustic properties compared to PVC foam. PVC foam offers a more cost-effective solution for applications prioritizing affordability and ease of fabrication, despite lower sound absorption efficiency. Businesses often choose PVC foam for large-scale projects to minimize expenses, whereas melamine foam is preferred when performance justifies the premium price.

Melamine Foam vs PVC Foam Infographic

materialdif.com

materialdif.com