Acoustic foam is specifically designed to absorb sound waves and reduce noise levels by minimizing echoes and reverberation, making it ideal for recording studios and home theaters. Insulation foam primarily serves as a thermal barrier, preventing heat transfer and improving energy efficiency in buildings, but it offers limited soundproofing capabilities. Choosing between acoustic foam and insulation foam depends on whether the priority is sound control or temperature regulation.

Table of Comparison

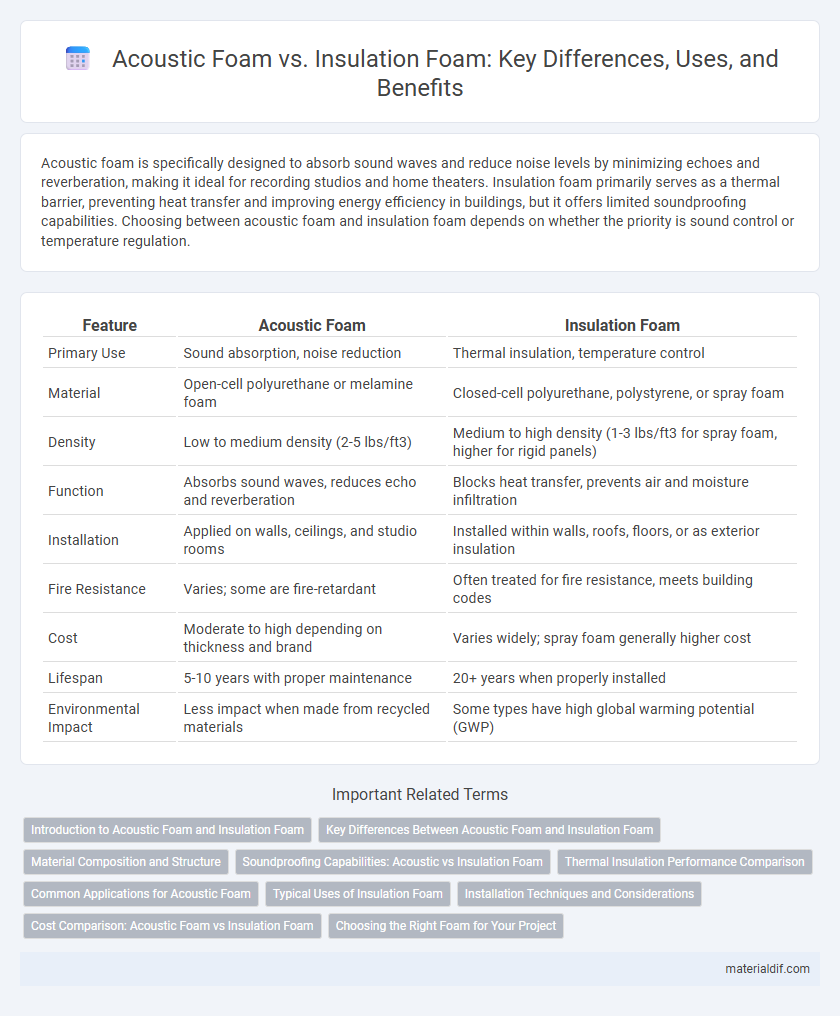

| Feature | Acoustic Foam | Insulation Foam |

|---|---|---|

| Primary Use | Sound absorption, noise reduction | Thermal insulation, temperature control |

| Material | Open-cell polyurethane or melamine foam | Closed-cell polyurethane, polystyrene, or spray foam |

| Density | Low to medium density (2-5 lbs/ft3) | Medium to high density (1-3 lbs/ft3 for spray foam, higher for rigid panels) |

| Function | Absorbs sound waves, reduces echo and reverberation | Blocks heat transfer, prevents air and moisture infiltration |

| Installation | Applied on walls, ceilings, and studio rooms | Installed within walls, roofs, floors, or as exterior insulation |

| Fire Resistance | Varies; some are fire-retardant | Often treated for fire resistance, meets building codes |

| Cost | Moderate to high depending on thickness and brand | Varies widely; spray foam generally higher cost |

| Lifespan | 5-10 years with proper maintenance | 20+ years when properly installed |

| Environmental Impact | Less impact when made from recycled materials | Some types have high global warming potential (GWP) |

Introduction to Acoustic Foam and Insulation Foam

Acoustic foam is specifically designed to absorb sound waves and reduce noise, making it ideal for studios, theaters, and recording environments. Insulation foam primarily provides thermal resistance to maintain temperature control in buildings, enhancing energy efficiency and preventing heat loss. While both types of foam share a similar cellular structure, their material composition and functional properties differ to address sound absorption versus thermal insulation.

Key Differences Between Acoustic Foam and Insulation Foam

Acoustic foam primarily targets sound absorption to reduce echoes and improve audio clarity, featuring a porous structure that traps sound waves effectively. Insulation foam focuses on thermal regulation, providing high R-values to limit heat transfer and maintain temperature stability within buildings. Unlike insulation foam, acoustic foam typically lacks significant thermal resistance and is not designed to prevent heat loss or gain.

Material Composition and Structure

Acoustic foam is typically made from open-cell polyurethane or melamine foam, designed with a porous structure that absorbs sound waves and reduces echo. Insulation foam, often composed of closed-cell materials such as extruded polystyrene (XPS) or spray polyurethane foam (SPF), features a dense, rigid structure aimed at thermal resistance and moisture barrier properties. The open-cell structure of acoustic foam enhances sound absorption, whereas the closed-cell structure of insulation foam maximizes heat retention and prevents air infiltration.

Soundproofing Capabilities: Acoustic vs Insulation Foam

Acoustic foam is specifically engineered to absorb sound waves and reduce echo, focusing on improving sound quality within a space rather than blocking sound transmission completely. Insulation foam primarily serves as a thermal barrier but provides minimal soundproofing due to its density and composition, which do not effectively dampen airborne noise. For effective soundproofing, acoustic foam outperforms insulation foam by targeting mid to high-frequency sounds and reducing reverberation.

Thermal Insulation Performance Comparison

Acoustic foam primarily targets sound absorption and noise reduction, offering limited thermal insulation properties due to its open-cell structure. Insulation foam, such as spray polyurethane foam (SPF) or rigid foam boards, features closed-cell construction that traps air, providing superior thermal resistance and reducing heat transfer efficiently. When comparing thermal insulation performance, insulation foam typically exhibits higher R-values per inch, making it more effective for energy conservation and temperature control than acoustic foam.

Common Applications for Acoustic Foam

Acoustic foam is commonly used in recording studios, home theaters, and broadcast rooms to reduce echo and improve sound clarity, making it essential for environments where audio quality is critical. Unlike insulation foam, which primarily focuses on thermal regulation in walls and attics, acoustic foam targets sound absorption by minimizing reverberation and controlling ambient noise levels. This specialized foam often features wedge or pyramid shapes designed to diffuse sound waves, enhancing acoustic performance in professional and residential spaces.

Typical Uses of Insulation Foam

Insulation foam is primarily used in building construction to enhance thermal efficiency by reducing heat transfer through walls, roofs, and floors, helping maintain consistent indoor temperatures. It is commonly applied in residential and commercial buildings to prevent energy loss, improve HVAC system performance, and increase overall energy savings. Unlike acoustic foam, which targets sound absorption, insulation foam is designed to provide a durable barrier against moisture, air infiltration, and temperature fluctuations.

Installation Techniques and Considerations

Acoustic foam installation typically involves adhesive sprays or mounting tapes to ensure precise placement on walls or ceilings, emphasizing sound absorption and minimizing vibration. Insulation foam requires expansion foam guns or spray equipment for application within wall cavities or around pipes, focusing on thermal resistance and air sealing properties. Proper surface preparation and moisture control are crucial for both foams to maximize longevity and performance.

Cost Comparison: Acoustic Foam vs Insulation Foam

Acoustic foam typically costs between $20 to $50 per panel, making it a more affordable option for soundproofing smaller areas, whereas insulation foam ranges from $0.30 to $1.50 per board foot, offering a cost-effective solution for thermal insulation on a larger scale. The price variation is influenced by factors such as density, material composition, and application purpose, with acoustic foam emphasizing sound absorption properties and insulation foam focusing on thermal resistance (R-value). For projects requiring soundproofing, acoustic foam offers specialized benefits at a higher unit cost compared to the broad thermal protection provided by insulation foam at a lower price per volume.

Choosing the Right Foam for Your Project

Acoustic foam specializes in sound absorption to reduce echo and noise within rooms, making it ideal for studios, theaters, and offices. Insulation foam primarily provides thermal resistance, helping to maintain temperature control in walls, ceilings, and floors. Selecting the right foam depends on project goals: choose acoustic foam for improving sound quality and insulation foam for energy efficiency and temperature regulation.

Acoustic foam vs Insulation foam Infographic

materialdif.com

materialdif.com