Reticulated foam features an open-cell structure with most cell membranes removed, offering superior air flow and filtration capabilities compared to non-reticulated foam, which retains closed cells that provide better cushioning and water resistance. The open pores in reticulated foam make it ideal for applications such as air and water filters, while non-reticulated foam excels in packaging and soundproofing due to its dense, energy-absorbing properties. Selecting between these foams depends on the need for permeability versus resilience in the intended use.

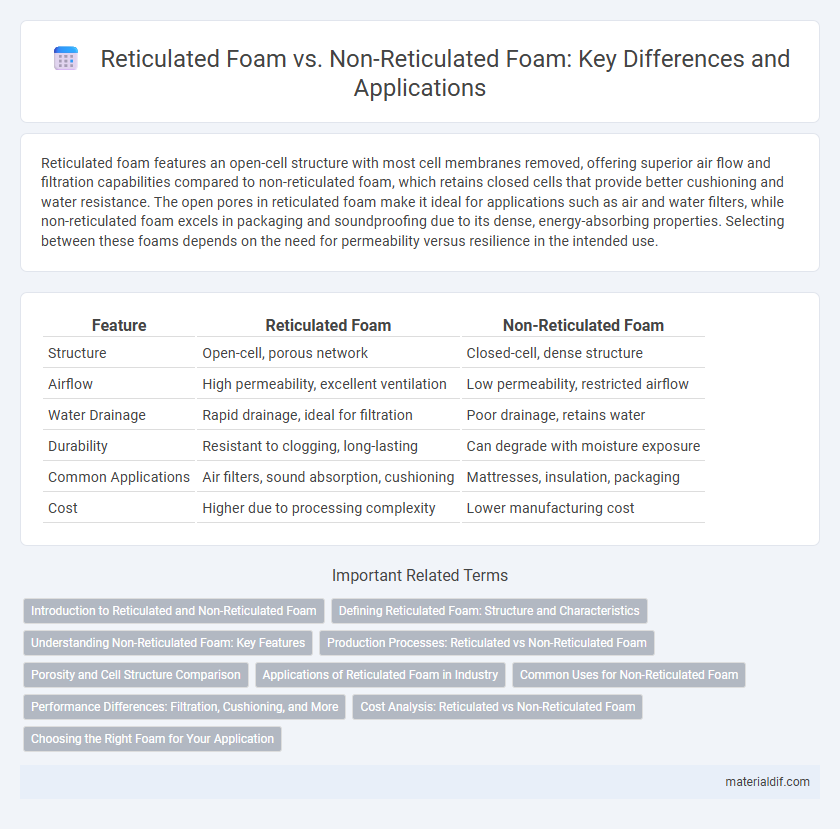

Table of Comparison

| Feature | Reticulated Foam | Non-Reticulated Foam |

|---|---|---|

| Structure | Open-cell, porous network | Closed-cell, dense structure |

| Airflow | High permeability, excellent ventilation | Low permeability, restricted airflow |

| Water Drainage | Rapid drainage, ideal for filtration | Poor drainage, retains water |

| Durability | Resistant to clogging, long-lasting | Can degrade with moisture exposure |

| Common Applications | Air filters, sound absorption, cushioning | Mattresses, insulation, packaging |

| Cost | Higher due to processing complexity | Lower manufacturing cost |

Introduction to Reticulated and Non-Reticulated Foam

Reticulated foam features an open-cell structure where cell membranes are removed, enhancing airflow and filtration efficiency, making it ideal for applications like air and water filters. Non-reticulated foam retains intact cell membranes, providing higher cushioning and shock absorption, commonly used in packaging and upholstery. The distinction in cell structure directly influences physical properties and suitability for specific industrial or consumer products.

Defining Reticulated Foam: Structure and Characteristics

Reticulated foam features an open-cell structure where the cell walls are removed, resulting in a network of interconnected strands that maximize airflow and liquid permeability. This porous design enhances filtration efficiency, sound absorption, and cushioning by allowing fluids and air to pass freely through the foam. In contrast to non-reticulated foam, which retains its closed-cell bubbles and offers greater insulation and rigidity, reticulated foam provides superior breathability and flexibility for specialized industrial and medical applications.

Understanding Non-Reticulated Foam: Key Features

Non-reticulated foam consists of a closed-cell structure that retains its original cell walls, providing superior cushioning, durability, and support compared to reticulated foam's open-cell design. Its water-resistant and shock-absorbing properties make it ideal for applications in mattress padding, protective packaging, and insulation. The dense, non-reticulated foam also offers excellent thermal insulation and noise reduction, enhancing comfort and protection in varied industrial and consumer uses.

Production Processes: Reticulated vs Non-Reticulated Foam

Reticulated foam is produced by removing the cell membranes of polyurethane foam through a chemical or thermal process, resulting in an open-cell structure that enhances airflow and liquid permeability. Non-reticulated foam retains its closed-cell structure as it is produced through standard polymerization without the additional reticulation step, providing greater cushioning and water resistance. The distinct production methods influence the foam's porosity, mechanical properties, and suitability for applications like filtration or padding.

Porosity and Cell Structure Comparison

Reticulated foam features an open-cell structure with high porosity, allowing for superior air and liquid flow, making it ideal for filtration and cushioning applications requiring breathability. Non-reticulated foam consists of closed cells with low porosity, providing greater resistance to moisture absorption and enhanced durability for padding and insulation purposes. The distinct difference in cell structure directly impacts their permeability, with reticulated foam offering up to 95% open cells versus the nearly airtight nature of non-reticulated foam.

Applications of Reticulated Foam in Industry

Reticulated foam features an open-cell structure that excels in filtration, sound absorption, and fluid flow applications across automotive, aerospace, and water treatment industries. Its highly porous design allows efficient air and liquid passage, making it ideal for air filters, cushioning, and catalytic converters. Reticulated foam's durability and resistance to clogging enhance performance in harsh industrial environments requiring reliable filtration and ventilation solutions.

Common Uses for Non-Reticulated Foam

Non-reticulated foam is widely used in applications requiring high filtration efficiency, such as air and liquid filtration systems, due to its intact cellular structure that traps particles effectively. It is also commonly found in cushioning materials, packaging, and noise reduction products where durability and shock absorption are essential. Medical applications often utilize non-reticulated foam for wound dressings and orthopedic supports because of its ability to retain moisture and provide softness.

Performance Differences: Filtration, Cushioning, and More

Reticulated foam features a highly porous open-cell structure, enhancing filtration efficiency by allowing fluids and air to pass through easily, whereas non-reticulated foam has a closed-cell design that traps particles and moisture, limiting filtration performance. In cushioning applications, non-reticulated foam offers superior support and durability due to its denser structure, while reticulated foam provides lighter cushioning with faster moisture wicking and breathability. The choice between reticulated and non-reticulated foam depends on specific requirements such as airflow, filtration capability, impact absorption, and environmental exposure.

Cost Analysis: Reticulated vs Non-Reticulated Foam

Reticulated foam, characterized by its open-cell structure, generally incurs higher manufacturing costs than non-reticulated foam due to additional processing steps like chemical or thermal reticulation. Non-reticulated foam offers cost advantages with simpler production and intact cell walls, making it more economical for applications requiring cushioning and insulation without high permeability. Cost analysis reveals that while reticulated foam's price premium supports specialized uses such as filtration and fluid flow, non-reticulated foam remains the cost-effective choice for general-purpose padding and noise reduction.

Choosing the Right Foam for Your Application

Reticulated foam offers a highly porous structure with open cells, making it ideal for filtration, sound absorption, and applications requiring rapid airflow or liquid permeability. Non-reticulated foam features closed cells that provide excellent cushioning, insulation, and moisture resistance, suitable for packaging, padding, and buoyancy uses. Selecting the right foam depends on balancing factors such as porosity, durability, and environmental exposure specific to the intended application.

Reticulated foam vs Non-reticulated foam Infographic

materialdif.com

materialdif.com