Reticulated foam features an open-cell structure that allows air, liquids, and light to pass through, making it ideal for filtration and cushioning that requires breathability. Skinned foam has a dense outer layer with a softer core, providing enhanced durability, impact resistance, and a smoother surface finish suitable for applications like seating and packaging. Choosing between reticulated and skinned foam depends on the need for ventilation and filtration versus robustness and surface integrity.

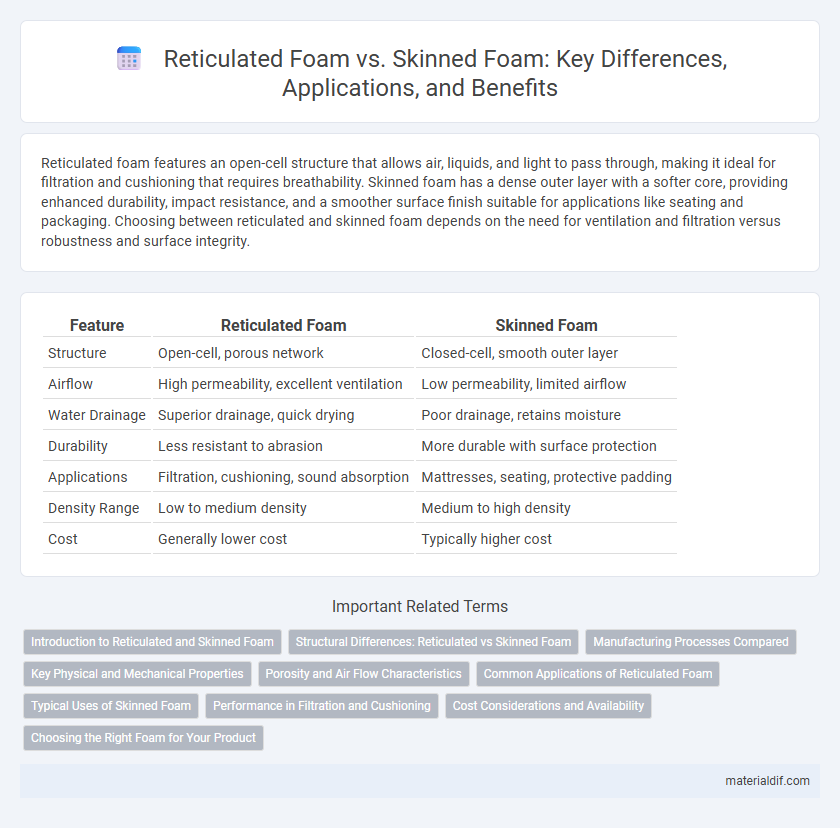

Table of Comparison

| Feature | Reticulated Foam | Skinned Foam |

|---|---|---|

| Structure | Open-cell, porous network | Closed-cell, smooth outer layer |

| Airflow | High permeability, excellent ventilation | Low permeability, limited airflow |

| Water Drainage | Superior drainage, quick drying | Poor drainage, retains moisture |

| Durability | Less resistant to abrasion | More durable with surface protection |

| Applications | Filtration, cushioning, sound absorption | Mattresses, seating, protective padding |

| Density Range | Low to medium density | Medium to high density |

| Cost | Generally lower cost | Typically higher cost |

Introduction to Reticulated and Skinned Foam

Reticulated foam features an open-cell structure with interconnected pores, making it highly breathable and ideal for filtration, cushioning, and filtration applications. Skinned foam has a dense outer layer with a closed-cell interior, providing durability, water resistance, and smooth surface finish. The unique structural differences between reticulated and skinned foam determine their suitability in industries such as automotive, packaging, and medical devices.

Structural Differences: Reticulated vs Skinned Foam

Reticulated foam features an open-cell structure where cell walls are removed, creating a porous network ideal for filtration and airflow applications. Skinned foam has a closed-cell surface layer, providing a denser, smoother exterior that enhances durability and resistance to moisture. The structural disparity between reticulated and skinned foam directly impacts their performance in cushioning, filtration, and insulation uses.

Manufacturing Processes Compared

Reticulated foam is manufactured through a chemical or thermal reticulation process that removes cell membranes, resulting in an open-cell structure optimized for filtration and cushioning applications. Skinned foam undergoes a molding or curing process that forms a closed, dense outer layer, providing enhanced durability and resistance to abrasion. The distinct manufacturing techniques lead to significant differences in physical properties, impacting their suitability for various industrial uses.

Key Physical and Mechanical Properties

Reticulated foam features an open-cell structure with high porosity, offering superior air and liquid permeability compared to skinned foam, which has a dense outer layer providing enhanced durability and impact resistance. Skinned foam exhibits greater tensile strength and compression set resistance, making it ideal for cushioning and protective applications, while reticulated foam excels in filtration and fluid flow scenarios due to its interconnected pores. The choice between reticulated and skinned foam hinges on the balance between breathability, structural integrity, and mechanical resilience required for specific industrial or consumer uses.

Porosity and Air Flow Characteristics

Reticulated foam features an open-cell structure with high porosity, allowing superior air flow and rapid moisture drainage, making it ideal for filtration and cushioning applications requiring breathability. In contrast, skinned foam has a dense outer layer with closed cells, resulting in lower porosity and restricted air flow, which provides better water resistance and durability but reduced ventilation. The choice between reticulated and skinned foam depends on the balance needed between air permeability and protection in specific use cases.

Common Applications of Reticulated Foam

Reticulated foam is widely used in filtration systems, air and water purification, and acoustic panels due to its high open-cell structure that allows for superior airflow and fluid passage. It is also common in cushioning for sports equipment, automotive seating, and medical devices where breathability and quick drainage are essential. Unlike skinned foam, reticulated foam excels in applications requiring enhanced ventilation and rapid drying.

Typical Uses of Skinned Foam

Skinned foam is commonly used in automotive seating, furniture cushions, and mattress toppers due to its smooth, durable outer layer that provides enhanced comfort and resistance to wear. Its closed-cell structure makes it ideal for applications requiring moisture resistance and a firmer support surface. Skinned foam also serves in packaging and insulation where protective, shock-absorbing properties are essential.

Performance in Filtration and Cushioning

Reticulated foam features an open-cell structure that excels in filtration by allowing air, liquids, and particulates to pass through efficiently, making it ideal for air and water filtration systems. Skinned foam, characterized by a dense outer layer with a softer core, provides superior cushioning due to its combination of firmness and comfort, commonly used in automotive seating and medical mattresses. The choice between reticulated and skinned foam depends on the specific performance needs: reticulated foam for high permeability and filtration efficiency, and skinned foam for enhanced support and impact absorption.

Cost Considerations and Availability

Reticulated foam typically incurs higher costs due to its intricate manufacturing process, which removes most cell walls to create an open-cell structure, making it less widely available than skinned foam. Skinned foam, characterized by its dense outer layer and closed-cell core, offers a more affordable and readily accessible option for applications requiring cushioning and insulation. Budget-sensitive projects often favor skinned foam for its balance of cost-efficiency and availability in various densities and sizes.

Choosing the Right Foam for Your Product

Reticulated foam features an open-cell structure with high permeability, making it ideal for filtration, cushioning, and airflow applications, while skinned foam offers a closed-cell outer layer that provides enhanced durability and water resistance. Selecting the right foam depends on product requirements such as breathability, structural support, and exposure to moisture. For applications needing robust protection and longevity, skinned foam is preferred, whereas reticulated foam suits environments requiring maximal ventilation and quick drainage.

Reticulated foam vs Skinned foam Infographic

materialdif.com

materialdif.com