Bonded foam consists of shredded foam pieces fused together, offering durability and cost-effectiveness, making it ideal for pet beds that require firmness and longevity. Molded foam, shaped in one solid piece, provides superior comfort and support by contouring to a pet's body, enhancing pressure relief and overall rest quality. Choosing between bonded and molded foam depends on your pet's specific needs for comfort versus durability.

Table of Comparison

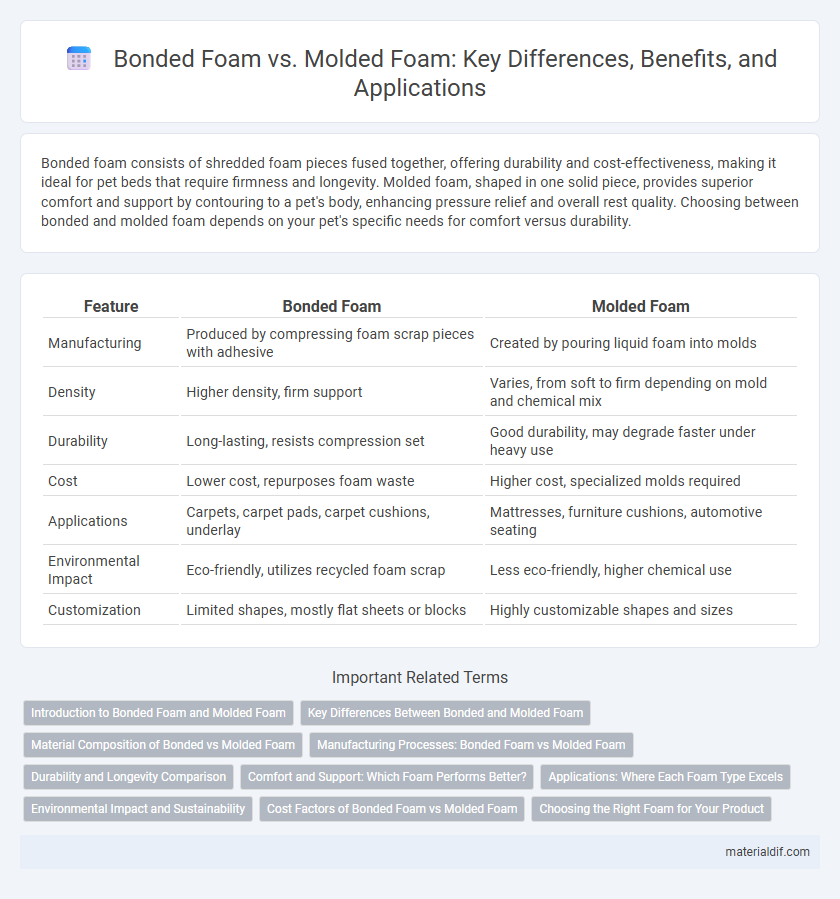

| Feature | Bonded Foam | Molded Foam |

|---|---|---|

| Manufacturing | Produced by compressing foam scrap pieces with adhesive | Created by pouring liquid foam into molds |

| Density | Higher density, firm support | Varies, from soft to firm depending on mold and chemical mix |

| Durability | Long-lasting, resists compression set | Good durability, may degrade faster under heavy use |

| Cost | Lower cost, repurposes foam waste | Higher cost, specialized molds required |

| Applications | Carpets, carpet pads, carpet cushions, underlay | Mattresses, furniture cushions, automotive seating |

| Environmental Impact | Eco-friendly, utilizes recycled foam scrap | Less eco-friendly, higher chemical use |

| Customization | Limited shapes, mostly flat sheets or blocks | Highly customizable shapes and sizes |

Introduction to Bonded Foam and Molded Foam

Bonded foam consists of layers of foam fused together using adhesive or heat, providing enhanced density and strength ideal for heavy-duty applications like automotive seating and industrial cushioning. Molded foam is created by pouring liquid foam into molds where it chemically reacts and expands, resulting in complex shapes and precise dimensions commonly used in packaging, sports equipment, and medical supports. Both types offer unique structural characteristics tailored for specific performance requirements in cushioning, insulation, and protective packaging.

Key Differences Between Bonded and Molded Foam

Bonded foam consists of layers of foam fused together, offering increased density and firmness, while molded foam is created by pouring liquid foam into molds for customized shapes and consistent density. Bonded foam is ideal for high-resilience applications requiring durability and impact resistance, whereas molded foam provides enhanced comfort and precise contouring for cushioning. The key differences lie in manufacturing processes, density uniformity, and typical uses across furniture, automotive, and packaging industries.

Material Composition of Bonded vs Molded Foam

Bonded foam is composed of multiple layers of foam fused together using adhesive agents or heat, typically combining different foam types such as polyurethane and memory foam to enhance durability and support. Molded foam is made from liquid foam that expands and solidifies within a mold, resulting in a cohesive structure often using high-density polyurethane to achieve precise shapes and consistent density. The material composition of bonded foam allows for varied stiffness and customized performance, whereas molded foam offers homogeneous material properties with enhanced resilience due to its monolithic formation.

Manufacturing Processes: Bonded Foam vs Molded Foam

Bonded foam is produced by layering and compressing sheets or pieces of foam using adhesives or heat, resulting in a dense, durable material ideal for cushioning and insulation. Molded foam is created through a chemical reaction within a mold, allowing the foam to expand and fill intricate shapes with consistent density and minimal waste. Manufacturing molded foam offers precise control over shape and thickness, whereas bonded foam manufacturing emphasizes strength and multi-layer structure.

Durability and Longevity Comparison

Bonded foam exhibits superior durability due to its dense structure created by compressing foam scraps, making it highly resistant to wear and tear over extended use. Molded foam, formed by pouring liquid foam into molds, offers consistent cell structure but may degrade faster under heavy stress and frequent compression. The lifespan of bonded foam typically surpasses molded foam, making it ideal for applications requiring long-lasting cushioning and support.

Comfort and Support: Which Foam Performs Better?

Bonded foam offers firmer support by compressing smaller foam pieces together, making it ideal for applications requiring durability and stability, but it may lack the plush comfort of molded foam. Molded foam, created from a single, solid block, provides superior contouring and pressure relief, enhancing comfort and support by adapting closely to body shape. For optimal comfort and support, molded foam typically outperforms bonded foam in applications like mattresses and cushions where body conformance is essential.

Applications: Where Each Foam Type Excels

Bonded foam excels in applications requiring high durability and impact resistance, making it ideal for automotive seating, soundproofing, and industrial padding. Molded foam is preferred for products demanding precise shapes and cushioning, such as athletic footwear, furniture cushions, and packaging for delicate electronics. Each foam type's unique properties optimize performance in their respective applications, balancing comfort, protection, and structural integrity.

Environmental Impact and Sustainability

Bonded foam is often considered more sustainable due to its ability to recycle scrap materials and reduce waste in production, while molded foam typically requires more energy-intensive processes and generates higher emissions. Molded foam benefits from closed-cell technology that enhances durability and longevity, potentially reducing the need for frequent replacement. Choosing bonded foam aligns better with environmental goals by minimizing landfill contributions and supporting circular economy practices.

Cost Factors of Bonded Foam vs Molded Foam

Bonded foam generally costs less due to its simpler manufacturing process, which involves laminating small foam pieces using adhesives, reducing material waste and production time. Molded foam, created through an injection molding process, incurs higher expenses from specialized molds and longer curing cycles, leading to increased tooling and labor costs. Evaluating project scale and performance requirements helps determine the cost-effectiveness between bonded and molded foam options.

Choosing the Right Foam for Your Product

Selecting the right foam for your product depends on factors like durability, shape complexity, and cushioning needs. Bonded foam offers excellent density and resistance to compression, making it ideal for support applications, while molded foam provides superior contouring and resilience, perfect for ergonomic designs. Assess product requirements carefully to balance comfort, longevity, and cost-effectiveness when choosing between bonded and molded foam.

Bonded Foam vs Molded Foam Infographic

materialdif.com

materialdif.com