Thermoformed foam offers precise shaping by heating foam sheets and forming them over molds, resulting in lightweight and customizable components ideal for packaging and protective cases. Molded foam is created by injecting or expanding foam materials into molds, producing durable, high-density parts suited for impact absorption and insulation. Both methods provide tailored solutions, but thermoforming excels in detail and flexibility, while molding delivers superior strength and consistency.

Table of Comparison

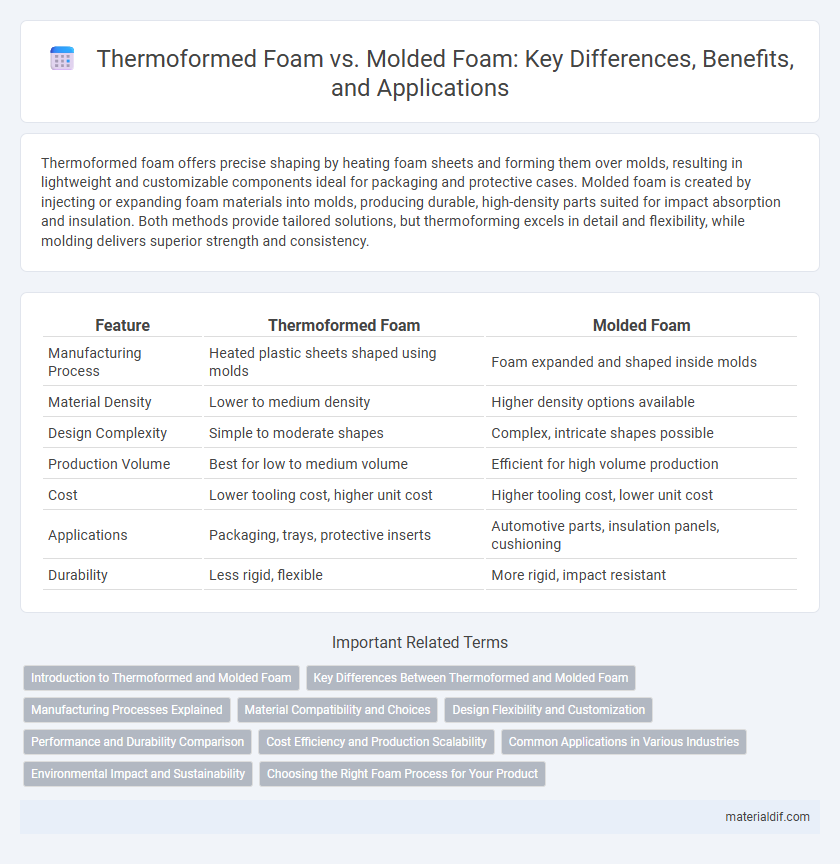

| Feature | Thermoformed Foam | Molded Foam |

|---|---|---|

| Manufacturing Process | Heated plastic sheets shaped using molds | Foam expanded and shaped inside molds |

| Material Density | Lower to medium density | Higher density options available |

| Design Complexity | Simple to moderate shapes | Complex, intricate shapes possible |

| Production Volume | Best for low to medium volume | Efficient for high volume production |

| Cost | Lower tooling cost, higher unit cost | Higher tooling cost, lower unit cost |

| Applications | Packaging, trays, protective inserts | Automotive parts, insulation panels, cushioning |

| Durability | Less rigid, flexible | More rigid, impact resistant |

Introduction to Thermoformed and Molded Foam

Thermoformed foam is created by heating foam sheets until pliable and then shaping them using molds or vacuum forming, resulting in lightweight, rigid components ideal for packaging and cushioning. Molded foam, on the other hand, involves injecting liquid foam into a mold where it expands and solidifies, producing complex shapes with excellent structural integrity commonly used in automotive and protective gear applications. Both techniques optimize foam properties for specific performance requirements, offering versatility across industries.

Key Differences Between Thermoformed and Molded Foam

Thermoformed foam is created by heating foam sheets and shaping them using a mold, resulting in precise contours and smooth surfaces ideal for packaging and protective inserts. Molded foam, produced by injecting or pouring liquid foam into molds, allows for complex shapes and higher density variations, commonly used in automotive seats and cushioning applications. Key differences include the manufacturing process, shape complexity, production speed, and typical applications, with thermoforming excelling in thin, lightweight parts and molding suited for intricate, durable components.

Manufacturing Processes Explained

Thermoformed foam is created by heating foam sheets until pliable, then pressing them into molds to achieve the desired shape, allowing for precise control over thickness and detail. Molded foam involves injecting liquid foam into a closed mold where it expands and cures, producing complex shapes with consistent density and strong structural integrity. Both processes offer distinct advantages: thermoforming excels in rapid prototyping and thin-walled components, while molding is ideal for high-strength, thicker, and more intricate foam products.

Material Compatibility and Choices

Thermoformed foam offers greater versatility in material compatibility, allowing the use of various polymers such as polyethylene, polystyrene, and polypropylene that respond well to heat and pressure during shaping. Molded foam primarily utilizes polyurethane and expanded polystyrene, which react chemically to form complex, durable shapes with superior cushioning properties. Selecting the appropriate foam type depends on the application's specific requirements for flexibility, durability, and resistance to environmental factors.

Design Flexibility and Customization

Thermoformed foam offers superior design flexibility by allowing precise contouring and intricate shapes through heat and vacuum or pressure forming, ideal for custom packaging and protective inserts. Molded foam excels in producing complex, three-dimensional parts with consistent density, providing durability and impact resistance for automotive and industrial applications. Customization in thermoformed foam adapts quickly to small production runs, while molded foam suits high-volume manufacturing with robust, repeatable design elements.

Performance and Durability Comparison

Thermoformed foam offers superior consistency and resilience due to its uniform cell structure, enhancing impact absorption and long-term shape retention, which makes it ideal for applications requiring repeated stress resistance. Molded foam excels in complex shapes and larger volumes, providing high density and rigidity but may exhibit slight variation in performance across different sections due to uneven cell distribution. In durability terms, thermoformed foam generally outperforms molded foam in maintaining structural integrity over time, while molded foam is preferred when intricate design and high load-bearing capacity are critical.

Cost Efficiency and Production Scalability

Thermoformed foam offers greater production scalability due to faster cycle times and less labor-intensive processes, making it cost-efficient for high-volume manufacturing. Molded foam, while often delivering superior structural integrity and complex shapes, tends to have higher tooling costs and longer production cycles, impacting its overall cost efficiency. Choosing between thermoformed and molded foam depends on balancing initial investment against production volume and desired foam characteristics.

Common Applications in Various Industries

Thermoformed foam is widely used in packaging, automotive interiors, and consumer electronics due to its lightweight structure and precise contouring capabilities. Molded foam finds common applications in protective gear, furniture cushions, and aerospace components where durability and complex shapes are essential. Both types are integral in medical devices, sports equipment, and insulation, catering to industry-specific performance requirements.

Environmental Impact and Sustainability

Thermoformed foam generally has a lower environmental impact than molded foam due to its more efficient material usage and energy consumption during production. Molded foam typically involves higher waste generation and greater energy input, which can increase its carbon footprint. Choosing thermoformed foam supports sustainability by reducing resource consumption and facilitating easier recycling processes.

Choosing the Right Foam Process for Your Product

Thermoformed foam offers precise shaping and is ideal for lightweight, rigid protective packaging, while molded foam provides higher density and durability for impact-resistant applications. Selecting the right foam process depends on factors such as product sensitivity, required cushioning, and production volume. Understanding the specific performance needs ensures optimal material efficiency and cost-effectiveness in packaging design.

Thermoformed foam vs Molded foam Infographic

materialdif.com

materialdif.com