EVA foam offers superior flexibility, durability, and shock absorption compared to EPE foam, making it ideal for sports equipment and protective gear. EPE foam is lightweight, resistant to moisture, and provides excellent cushioning, commonly used in packaging and insulation. Choosing between EVA and EPE foam depends on the specific application requirements for resilience, comfort, and environmental exposure.

Table of Comparison

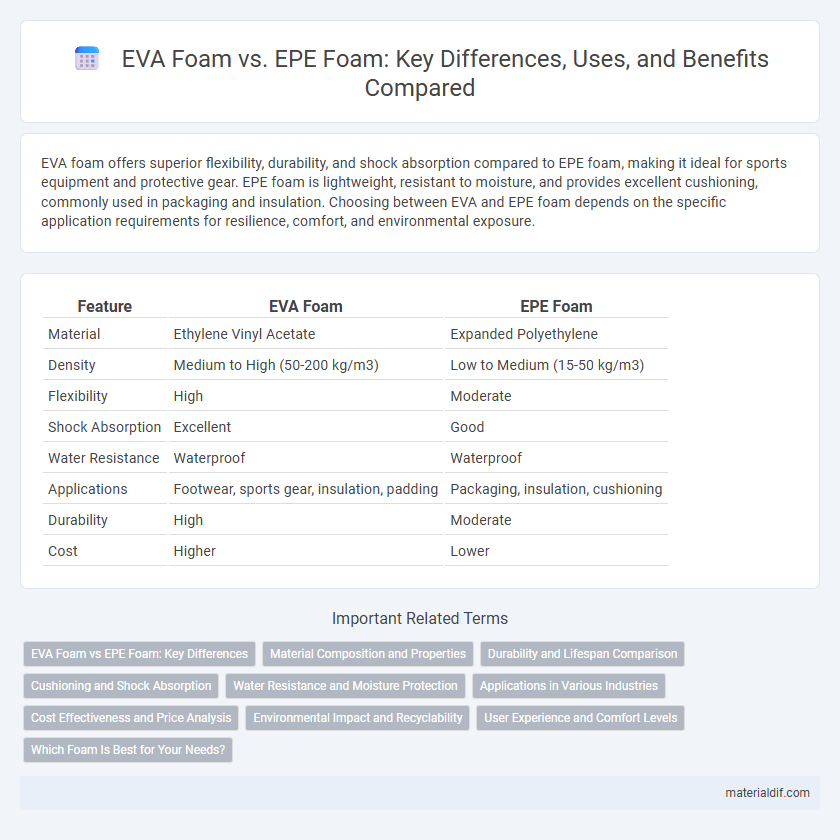

| Feature | EVA Foam | EPE Foam |

|---|---|---|

| Material | Ethylene Vinyl Acetate | Expanded Polyethylene |

| Density | Medium to High (50-200 kg/m3) | Low to Medium (15-50 kg/m3) |

| Flexibility | High | Moderate |

| Shock Absorption | Excellent | Good |

| Water Resistance | Waterproof | Waterproof |

| Applications | Footwear, sports gear, insulation, padding | Packaging, insulation, cushioning |

| Durability | High | Moderate |

| Cost | Higher | Lower |

EVA Foam vs EPE Foam: Key Differences

EVA foam offers superior elasticity, durability, and chemical resistance compared to EPE foam, making it ideal for applications requiring cushioning and shock absorption. EPE foam is lighter, more cost-effective, and provides excellent thermal insulation, often used in packaging and insulation. The key differences include EVA foam's closed-cell structure and resilience versus EPE foam's expanded polyethylene composition and lower density.

Material Composition and Properties

EVA foam, made from ethylene-vinyl acetate copolymer, offers a flexible, durable, and soft texture with excellent shock absorption and resistance to UV radiation, making it ideal for sports equipment and footwear. EPE foam, composed of expanded polyethylene beads, features a lightweight structure with superior cushioning, high resiliency, and good resistance to moisture, commonly used in packaging and insulation. The molecular structure of EVA provides enhanced elasticity and stress crack resistance, while EPE's closed-cell design ensures excellent water resistance and thermal insulation properties.

Durability and Lifespan Comparison

EVA foam offers superior durability with high resistance to cracking, UV rays, and compression set, making it ideal for heavy-use applications and outdoor conditions. EPE foam provides moderate durability, excelling in impact absorption but degrading faster under prolonged stress or exposure to environmental factors. The lifespan of EVA foam typically exceeds 5 years with proper care, whereas EPE foam generally lasts around 2 to 3 years before significant wear occurs.

Cushioning and Shock Absorption

EVA foam offers superior cushioning and shock absorption due to its closed-cell structure that provides excellent resilience and energy return. EPE foam, while lightweight and buoyant, has a more open-cell composition, resulting in less effective impact resistance and cushioning properties. For applications requiring enhanced protection and comfort, EVA foam is generally the preferred choice over EPE foam.

Water Resistance and Moisture Protection

EVA foam offers superior water resistance and moisture protection compared to EPE foam, making it ideal for applications exposed to wet environments. Its closed-cell structure prevents water absorption, ensuring durability and cushioning performance over time. EPE foam, while lightweight and flexible, tends to absorb moisture more readily, which can compromise its insulating properties and lead to degradation.

Applications in Various Industries

EVA foam's resilience, flexibility, and shock absorption make it ideal for footwear soles, sports equipment, and protective padding in automotive and healthcare industries. EPE foam excels in lightweight packaging, insulation, and cushioning delicate electronics due to its closed-cell, water-resistant structure. Both foams serve vital roles in manufacturing, with EVA favored for durability and comfort and EPE preferred for impact protection and thermal insulation.

Cost Effectiveness and Price Analysis

EVA foam generally offers higher durability and flexibility but comes at a higher price compared to EPE foam, which is more affordable and provides sufficient cushioning for basic applications. Cost-effectiveness depends on the intended use, as EVA foam's longer lifespan may reduce replacement costs, while EPE foam's lower upfront price suits budget-sensitive projects. Price analysis reveals EVA foam typically ranges from $2.50 to $4.50 per square foot, whereas EPE foam costs between $1.00 and $2.00 per square foot, influencing material selection in industrial and packaging sectors.

Environmental Impact and Recyclability

EVA foam offers better recyclability due to its thermoplastic nature, enabling repeated melting and reshaping with less environmental waste compared to EPE foam. EPE foam, often composed of expanded polyethylene, is lightweight and cushioning but poses more challenges in recycling and typically contributes more to landfill volume. EVA foam's lower environmental impact is enhanced by its potential for chemical recycling and reduced release of harmful additives during degradation.

User Experience and Comfort Levels

EVA foam offers superior cushioning and durability, providing enhanced shock absorption and a softer feel that improves user comfort during prolonged use. EPE foam, while lighter and more cost-effective, has a firmer texture that may result in less comfort over extended periods. Users seeking long-lasting comfort and flexibility typically prefer EVA foam for applications like footwear insoles and sports equipment.

Which Foam Is Best for Your Needs?

EVA foam offers superior durability, elasticity, and shock absorption, making it ideal for fitness mats, sports equipment, and footwear insoles. EPE foam excels in lightweight cushioning and thermal insulation with excellent water resistance, suitable for packaging, insulation, and floatation devices. Choose EVA foam for high-impact applications requiring resilience, while EPE foam is best for lightweight, moisture-resistant uses.

EVA foam vs EPE foam Infographic

materialdif.com

materialdif.com