Buoyant foam contains gas-filled cells that trap air, making it lighter than water and enabling it to float on the surface. Non-buoyant foam has a denser structure with less trapped air, causing it to sink or remain submerged in liquids. The difference in buoyancy affects applications ranging from flotation devices to insulation materials.

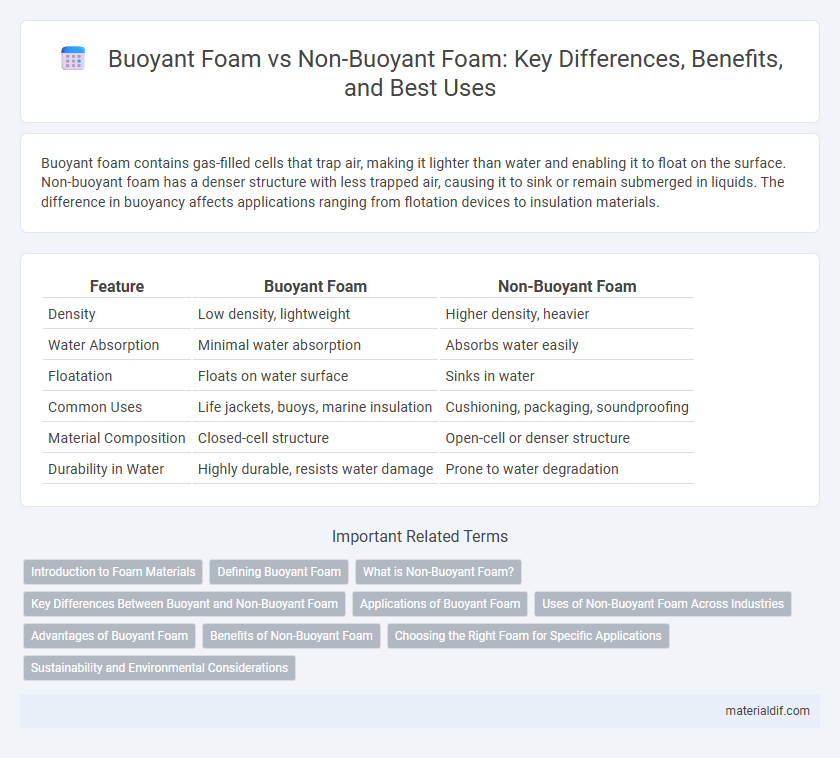

Table of Comparison

| Feature | Buoyant Foam | Non-Buoyant Foam |

|---|---|---|

| Density | Low density, lightweight | Higher density, heavier |

| Water Absorption | Minimal water absorption | Absorbs water easily |

| Floatation | Floats on water surface | Sinks in water |

| Common Uses | Life jackets, buoys, marine insulation | Cushioning, packaging, soundproofing |

| Material Composition | Closed-cell structure | Open-cell or denser structure |

| Durability in Water | Highly durable, resists water damage | Prone to water degradation |

Introduction to Foam Materials

Buoyant foam materials, such as expanded polystyrene and closed-cell polyurethane, possess low density and high air content, enabling them to float on water and provide effective insulation and flotation support. Non-buoyant foams, including open-cell polyurethane and melamine foam, have higher density and absorb water, causing them to sink and making them suitable for applications requiring sound absorption and cushioning. Understanding the distinct physical properties of buoyant versus non-buoyant foam is essential for selecting the appropriate material in marine, construction, or packaging industries.

Defining Buoyant Foam

Buoyant foam is a lightweight material designed with an open-cell structure that traps air, allowing it to float on water. Its low density and high air content provide inherent flotation properties essential for marine applications, life vests, and insulation in wet environments. In contrast, non-buoyant foam lacks sufficient air retention, making it denser and unable to support weight in water.

What is Non-Buoyant Foam?

Non-buoyant foam is a type of foam that absorbs water or has a density higher than that of water, causing it to sink rather than float. Unlike buoyant foam, which contains trapped air pockets for flotation, non-buoyant foam lacks sufficient air content or uses materials that increase its weight and water absorption properties. This makes non-buoyant foam suitable for applications requiring weight, stability, or submersion, such as soundproofing or vibration damping.

Key Differences Between Buoyant and Non-Buoyant Foam

Buoyant foam contains closed-cell structures filled with air or gas, providing natural flotation and preventing water absorption, unlike non-buoyant foam, which features open-cell configurations that absorb water and lose volume. Key differences include density, water resistance, and application suitability: buoyant foam is ideal for marine and flotation devices, while non-buoyant foam is used for cushioning, insulation, and packaging where water exposure is minimal. Thermal insulation properties and compressive strength also vary, with buoyant foam typically offering higher resistance to compression and moisture-induced degradation.

Applications of Buoyant Foam

Buoyant foam, characterized by its low density and high air content, is extensively used in marine and safety applications such as life jackets, flotation devices, and buoyancy aids for watercraft. Its ability to provide reliable support and prevent sinking makes it essential for rescue operations and recreational water activities. Industries also utilize buoyant foam in offshore oil rigs and underwater pipelines to enhance stability and safety.

Uses of Non-Buoyant Foam Across Industries

Non-buoyant foam is extensively utilized in industries such as automotive manufacturing for soundproofing and insulation, as well as in construction for thermal insulation and cushioning. Its dense, non-floating properties make it ideal for applications requiring stability and support without buoyancy. Additionally, packaging industries rely on non-buoyant foam to protect heavy or delicate goods during transportation and storage.

Advantages of Buoyant Foam

Buoyant foam offers superior flotation properties, making it ideal for marine applications, life vests, and emergency flotation devices. Its lightweight structure provides excellent water resistance and maintains stability even under pressure, enhancing safety and durability. Non-buoyant foam lacks these characteristics, limiting its usability in situations requiring reliable buoyancy and impact absorption.

Benefits of Non-Buoyant Foam

Non-buoyant foam excels in fire resistance and structural stability, making it ideal for insulation and soundproofing in construction. Its density and ability to absorb impact contribute to enhanced durability and safety in automotive and industrial applications. Unlike buoyant foam, it prevents moisture absorption, reducing the risk of mold and corrosion in critical environments.

Choosing the Right Foam for Specific Applications

Buoyant foam, such as closed-cell polyethylene or EVA foam, is ideal for applications requiring flotation, insulation, and impact absorption, commonly used in marine, safety, and sports equipment. Non-buoyant foam, typically open-cell polyurethane or melamine foam, excels in soundproofing, cushioning, and filtration tasks due to its porous structure that allows air or liquids to pass through. Selecting the right foam depends on factors like density, water resistance, and specific performance needs to ensure optimal functionality in fields like construction, packaging, and automotive industries.

Sustainability and Environmental Considerations

Buoyant foam, designed to float and resist water absorption, often incorporates recycled materials and low-toxicity additives, enhancing its sustainability profile by reducing environmental impact during use and disposal. Non-buoyant foam typically absorbs water and may degrade faster, leading to microplastic pollution if not properly managed, challenging its environmental compatibility. Selecting buoyant foam with eco-friendly constituents and recyclable properties aligns with sustainable practices by minimizing waste and supporting circular economy principles.

Buoyant foam vs Non-buoyant foam Infographic

materialdif.com

materialdif.com