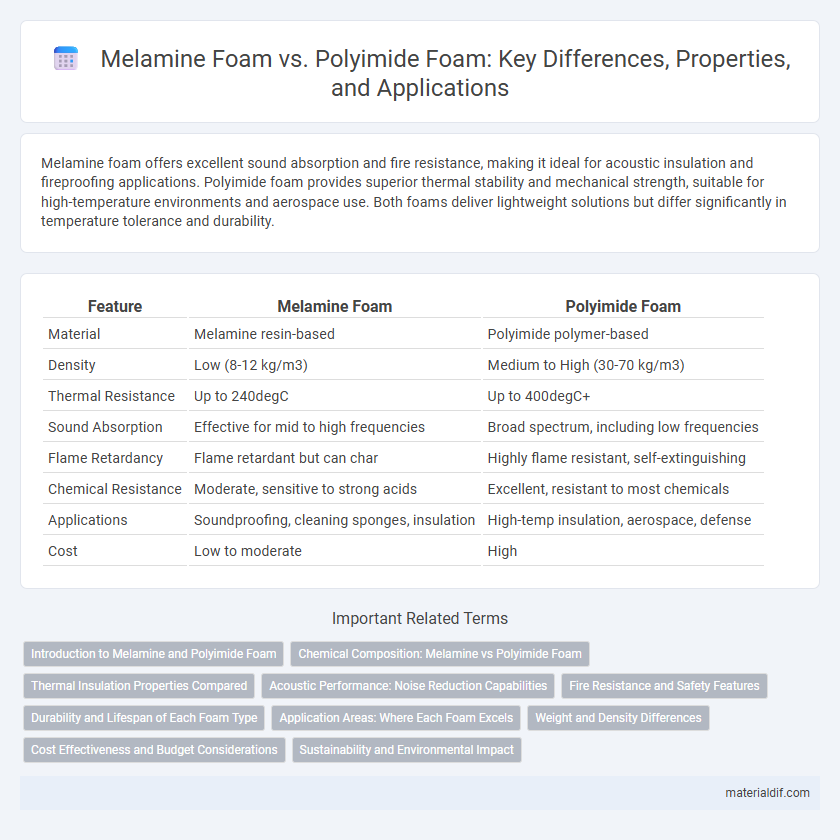

Melamine foam offers excellent sound absorption and fire resistance, making it ideal for acoustic insulation and fireproofing applications. Polyimide foam provides superior thermal stability and mechanical strength, suitable for high-temperature environments and aerospace use. Both foams deliver lightweight solutions but differ significantly in temperature tolerance and durability.

Table of Comparison

| Feature | Melamine Foam | Polyimide Foam |

|---|---|---|

| Material | Melamine resin-based | Polyimide polymer-based |

| Density | Low (8-12 kg/m3) | Medium to High (30-70 kg/m3) |

| Thermal Resistance | Up to 240degC | Up to 400degC+ |

| Sound Absorption | Effective for mid to high frequencies | Broad spectrum, including low frequencies |

| Flame Retardancy | Flame retardant but can char | Highly flame resistant, self-extinguishing |

| Chemical Resistance | Moderate, sensitive to strong acids | Excellent, resistant to most chemicals |

| Applications | Soundproofing, cleaning sponges, insulation | High-temp insulation, aerospace, defense |

| Cost | Low to moderate | High |

Introduction to Melamine and Polyimide Foam

Melamine foam is a lightweight, open-cell material known for its excellent sound absorption, thermal insulation, and fire resistance, commonly used in construction and acoustic applications. Polyimide foam offers superior thermal stability, mechanical strength, and chemical resistance, making it ideal for aerospace, electronics, and high-temperature environments. Both materials serve specialized roles, with melamine foam excelling in cost-effective insulation and soundproofing, while polyimide foam provides durability under extreme conditions.

Chemical Composition: Melamine vs Polyimide Foam

Melamine foam consists primarily of melamine-formaldehyde resin, a thermosetting polymer known for its open-cell structure and excellent sound absorption and thermal insulation properties. Polyimide foam is made from polyimide polymers characterized by aromatic imide rings, offering superior thermal stability, chemical resistance, and flame retardancy. The distinct chemical compositions of melamine and polyimide foams result in different performance profiles, with melamine foam excelling in lightweight cushioning applications and polyimide foam preferred for high-temperature and harsh chemical environments.

Thermal Insulation Properties Compared

Melamine foam exhibits low thermal conductivity around 0.031 W/m*K, making it highly effective for heat insulation in applications requiring lightweight, fire-resistant materials. Polyimide foam offers superior thermal stability with a thermal conductivity typically between 0.03 and 0.05 W/m*K, maintaining performance at temperatures up to 300degC or higher. While melamine foam excels in acoustic absorption and flame retardancy, polyimide foam is preferred for extreme temperature environments due to its outstanding heat resistance and mechanical durability.

Acoustic Performance: Noise Reduction Capabilities

Melamine foam offers superior noise absorption with an NRC (Noise Reduction Coefficient) typically between 0.75 and 0.85, making it ideal for reducing mid to high-frequency sounds in acoustic treatments. Polyimide foam exhibits excellent thermal stability and mechanical strength but generally has a lower NRC around 0.60 to 0.70, which limits its effectiveness in comprehensive noise reduction applications. The open-cell structure and fine pore size of melamine foam contribute to its enhanced ability to trap sound waves and reduce reverberation compared to polyimide foam, especially in indoor environments.

Fire Resistance and Safety Features

Melamine foam exhibits excellent fire resistance due to its inherent non-combustible structure and ability to char rather than ignite, making it suitable for high-temperature applications and enhancing safety by reducing toxic smoke emissions. Polyimide foam offers superior thermal stability, maintaining structural integrity at temperatures exceeding 400degC, and provides enhanced flame retardancy with low smoke generation, crucial for aerospace and industrial safety standards. Both foams are preferred for fire-resistant insulation, but polyimide foam outperforms melamine foam in extreme heat environments requiring advanced safety.

Durability and Lifespan of Each Foam Type

Melamine foam offers moderate durability with resistance to compression and thermal degradation, making it suitable for repeated cleaning tasks but prone to brittleness over extended use. Polyimide foam exhibits superior durability and an extended lifespan, maintaining structural integrity under high temperatures, chemical exposure, and mechanical stress. The enhanced resilience of polyimide foam makes it ideal for demanding industrial applications requiring long-term performance.

Application Areas: Where Each Foam Excels

Melamine foam excels in soundproofing, thermal insulation, and fire-retardant applications within automotive interiors, construction, and HVAC systems due to its open-cell structure and excellent acoustic absorption. Polyimide foam is preferred in aerospace, electronics, and high-temperature sealing because of its outstanding thermal stability, chemical resistance, and lightweight properties. Each foam's unique thermal and mechanical characteristics make them ideal for specific industrial uses where performance under extreme conditions or effective noise control is critical.

Weight and Density Differences

Melamine foam typically offers a lightweight structure with a density ranging from 9 to 22 kg/m3, making it ideal for acoustic insulation and soundproofing applications. Polyimide foam, on the other hand, exhibits higher density values, generally between 30 to 200 kg/m3, providing enhanced thermal stability and mechanical strength. The significant weight difference, driven by the denser polyimide foam, influences suitability for aerospace and high-performance engineering uses where durability outweighs minimal mass.

Cost Effectiveness and Budget Considerations

Melamine foam offers a cost-effective solution for insulation and soundproofing applications, with lower material costs and widespread availability making it ideal for budget-conscious projects. Polyimide foam, while more expensive, provides superior thermal stability and chemical resistance, justifying its higher price in high-performance or specialized environments. Budget considerations must weigh the upfront cost of melamine foam against the long-term durability and enhanced properties of polyimide foam for optimal value.

Sustainability and Environmental Impact

Melamine foam offers excellent fire resistance and is recyclable, but its production relies on formaldehyde-based resins, raising concerns about VOC emissions and toxicity. Polyimide foam boasts superior thermal stability and durability, with a production process that generally involves fewer hazardous chemicals, leading to a lower environmental footprint. Both foams contribute to energy savings through insulation, but polyimide foam's longer lifespan and reduced chemical hazards make it a more sustainable choice in environmentally sensitive applications.

Melamine foam vs Polyimide foam Infographic

materialdif.com

materialdif.com